Nanolayers Enter Blow Molding

Technology mirrors Dow's recent development in blown film.

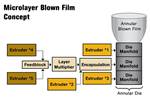

Dow Chemical Co., Midland, Mich., has adopted nanolayer technology developed for blown film (the film technology was discussed in our June issue). At the recent SPE ANTEC in Boston, a paper by Dow’s S. Crabree, J. Dooley, J. Robacki, P.C. Lee, R. Wrisley, and C. Pavlicek detailed technology that used feedblock and flow-divider technology more common in flat-die extrusion, as well as a specially configured die head to produce blow molded bottles containing more than 30 layers.

Related Content

-

Coca-Cola Europacific Transitions to Tethered Caps and Lighter PET Bottle

Sidel is converting all Coca-Cola PET bottling lines in Europe to meet new EU packaging regulations by July 2024.

-

First Water Bottles With Ultrathin Glass Coating

Long used for sensitive juices and carbonated soft drinks, KHS Freshsafe PET Plasmax vapor-deposited glass coating is now providing freshness and flavor protection for PET mineral water bottles.

-

Services to Help Blow Molders Convert to rPET

Sidel launches “RePETable” range of services as “one-stop” solution to efficient adoption of rPET for bottle production.