New Low-Pressure Process Molds Long Profiles On Small Presses

A new process that can produce long, thin-walled profiles and strips with functional or decorative geometries integrated in the part in a single step was developed by IB Steiner engineering consultants and Hybrid Composite Products GmbH, both in Spielberg, Austria.

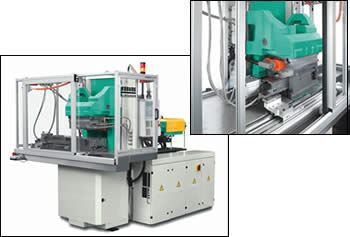

A new process that can produce long, thin-walled profiles and strips with functional or decorative geometries integrated in the part in a single step was developed by IB Steiner engineering consultants and Hybrid Composite Products GmbH, both in Spielberg, Austria. Their Exjection process uses a moving mold to incorporate projections or geometry changes into a long profile (difficult or impossible to achieve by extrusion) while inducing low stress and using relatively small injection machines. Molded parts can incorporate features like screw bosses, snap-fit hooks, end caps, or ribs, which are molded on the profile as the mold travels past a stationary hot-runner nozzle. Applications can include aircraft, automotive, construction, packaging, appliance, and lighting parts. As reported previously, this process is newly available on presses from Arburg and Engel.

LOW CLAMP FORCE

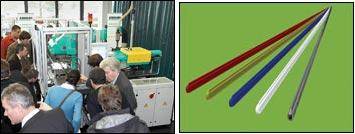

The Exjection process was first used to produce parts up to 1000 mm long with a cross-section of 10 x 16 mm, and a wall thickness from 1.5 to 1.8 mm on a 50-ton press, says Herbert Eichler, IB Steiner’s quality manager and project engineer for assemblies and technology development. Today, parts up to 2.5 meters long or longer can be produced on the same size press.

The process uses a mold that travels horizontally or vertically past the injection point and is designed to fill a small, continuously moving cross-section of the cavity. Since the injection step fills only a small cross-section of the part at a time, less clamp force is needed and parts have low internal stress, says Gottfried Steiner, who founded IB Steiner in 1995 and Hybrid Composite Products in 2005. Proprietary control software and pressure sensors at the beginning and ending of fill synchronize the movement of the mold carriage with the injection speed for uniform filling pressure. Because the mold moves, the gate is always just behind the melt front.

Exjection can be used on a horizontal or vertical press. The drive unit for the mold carriage can be integrated into either the mold or the machine. For very long parts, it is generally advisable to move the mold horizontally, since the weight of the carriage is more easily supported in that configuration. Also, ceiling height could limit movement of very long molds.

Use of the Exjection process involves a one-time payment of 40,000 Euros (around $61,600) for a non-exclusive production license for one production cell. There are no restrictions on the number of different products or pieces produced. Five companies have obtained more than 10 licenses so far. The first licensee, Ferdinand Stuekerjuergen GmbH in Rietberg-Varensell, Germany, a maker of aircraft interior parts, starts production this month.

Investment in equipment and systems for Exjection is roughly 30% to 50% less than it would be to mold the same parts conventionally, because of the lower tonnage required. Says Eichler, “With Exjection, machine size depends on the capacity of the plasticizing unit, not on the clamp force required or spacing between the platens. For a part about 1 meter long, you can use an injection molding machine with a clamp force between 50 tons and 150 tons. Without Exjection, a standard injection machine of around 500 tons would be needed to handle the mold. For a 2-meter part, the normal machine size would be up to 1500 tons.”

The process had its world premiere at the K 2007 show in Germany, where Engel molded strips on a 60-ton, all-electric e-motion 200/55 press. Arburg, at its annual Technology Days conference earlier this year, produced a 640-mm-long, 60-g rail from ABS in a 45-sec cycle on its new 55-ton Allrounder 375 V 500-290 vertical hydraulic machine. Eichler says a tool of that size would typically require a 300- to 500-ton press.

HOW IT WORKS

The mold is placed in a moving carriage driven by an electric motor and ball screw. The “variotherm” tool has a hot zone on one side of the nozzle, and a cold zone on the other side. The hot (supply) zone is typically set about 20° C below the melt temperature of the material being used. The temperature on the cold (calibration) zone is set at the recommended mold temperature for the material. As the mold carriage moves, the melt passes stationary areas on the fixed nozzle side that help to calibrate and then cool the profile. “The supply zone of the nozzle side works like an extrusion die and is heated. The calibration zone of the nozzle side works like an extrusion calibration unit and is cooled,” says Steiner. “You have to ensure that the melt is cooled to a frozen state before the cavity leaves the calibration zone.” Carriage speed typically ranges between 50 and 100 mm/sec. “If the rate is too fast or too slow, poor part quality will result,” says Eichler.

Filling pressure of several hundred bar develops at the nozzle. This pressure remains basically constant during filling (assuming a constant part cross-section) and is independent of the length of the part.

Exjection can be used with a wide range of commodity, engineering, and high-performance materials, from PP to PEEK. Higher resin viscosity is generally advantageous because it helps create a higher filling/holding pressure. (The only holding pressure in this process is the pressure of incoming melt against previously injected material.) Even extrusion grades can be used.

Eichler adds, “We can process the material at a much lower temperature then is typically used for injection molding. Together with low shear rates, this gentle processing of the melt results in better material properties in the part.”

Exjection can also be used with hard/soft molding, inserts, glass fiber or wood fillers, and in-mold decorating or lamination.

Related Content

Back to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreKnow Your Options in Injection Machine Nozzles

Improvements in nozzle design in recent years overcome some of the limitations of previous filter, mixing, and shut-off nozzles.

Read MoreInjection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

Read MoreRead Next

New Injection Machines and Processes To Debut at K 2007

A brand-new line of all-electric machines priced on par with comparable hydraulic presses and the first public demonstration of insert molding RFID chips into plastic parts will be two highlights of the Engel display at the mammoth K 2007 show in Dusseldorf, Germany, this October.

Read MoreNew Presses, Robots And Low-Pressure Process

At its annual Technology Days conference and exhibition in Lossburg, Germany, Arburg GmbH + Co.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More