New Screen Changer Boosts Productivity, Cuts Scrap for Extruder of PET Strapping

Cyklop’s move to a new-model, high-efficiency screen changer reduces number of screen changes and backflush waste while yielding uniform melt flow and high throughputs.

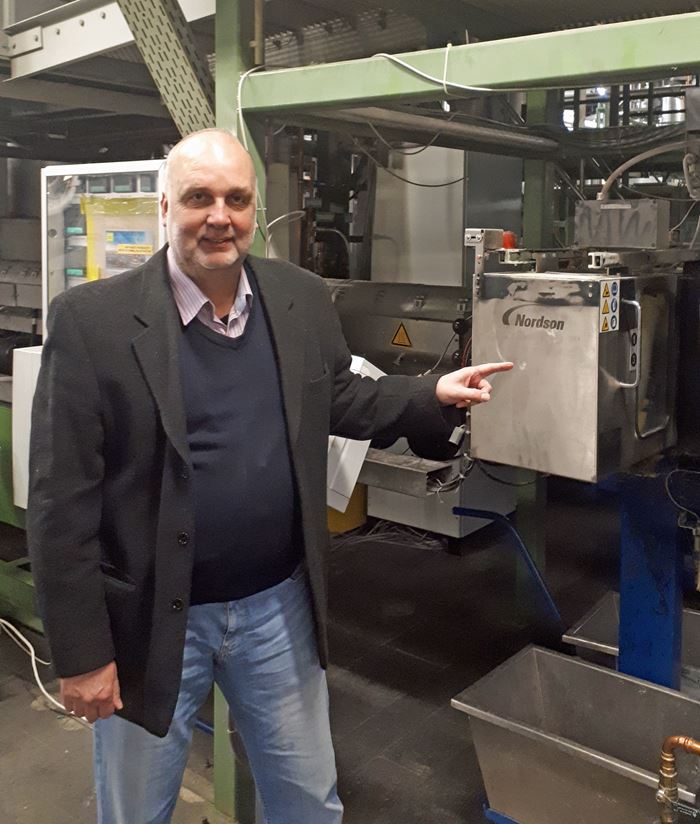

An advanced melt-filtration system has enabled Cyklop, an international supplier of industrial packaging systems for load securement, to increase productivity, reduce downtime, and cut material waste in the production of strapping tape from PET bottle flake. At its facility in Cologne, Germany, Cyklop GmbH replaced an older hydraulically powered backflush screen changer with the recently introduced BKG HiCon V-Type 3G system from

Nordson (U.S. office: Nordson Xaloy, Hickory, N.C.). Cyklop reports that the new screen changer reduces operating costs because it needs 30% fewer backflushes and requires screen changes 40% less frequently. Employed in a production line at throughput rates of 992 to 1212 lb/hr, the HiCon V-Type 3G system maintains flow and melt pressure at constant levels, ensuring uniform product quality, according to Bernd Causemann, Cyklop plant manager.

“The BKG HiCon V-Type 3G screen changer requires less maintenance and operator supervision than either the older Nordson system or a backflush system from a competing supplier,” states Causemann. “The higher efficiency of the V-Type 3G screen changer means fewer backflushes and less material waste. The system is particularly good in dealing with contamination surges, since the filtration area is regenerated very effectively in a short time.”

In the new screen changer, melt flow from the extruder is split at the entry side and guided to four screen cavities on two screen-bearing pistons with screens in each cavity. Each pair of cavities is positioned so they can filter their respective melt streams, until the piston removes one of the cavities from the process to remove contaminant buildup by means of backflushing. In normal operation, polymer is flowing through all four cavities. While one of the screens in the cavities is changed or flushed, the other three—or 75% of screening capacity—remain in the process so that throughput remains uninterrupted.

The backflushing cycle is automated. In addition to the two screen-bearing pistons, there is a single hydraulically actuated displacement piston that operates during backflushing. When the differential pressure across the screen changer increases to a preset level because of contaminant buildup, the backflush sequence for all cavities will be started automatically. For each cavity, the displacement piston retracts, creating a reservoir of filtered molten polymer.

This material is then hydraulically compressed and discharged in reverse direction, back through the screen, carrying away contaminant for removal from the system. The sequence is performed for each cavity, one after the other.

“In comparison with the earlier V-Type system, the height of the new version has been reduced by 30%, permitting a lower extrusion height,” notes Christian Schroeder, global product manager for BKG melt-delivery products. “A single displacement piston is used for backflushing instead of having one for each screen cavity; and hydraulic piping has been optimized.”

Related Content

-

How Screw Design Can Boost Output of Single-Screw Extruders

Optimizing screw design for a lower discharge temperature has been shown to significantly increase output rate.

-

What to Know About Your Materials When Choosing a Feeder

Feeder performance is crucial to operating extrusion and compounding lines. And consistent, reliable feeding depends in large part on selecting a feeder compatible with the materials and additives you intend to process. Follow these tips to analyze your feeder requirements.

-

How to Select the Right Tooling for Pipe Extrusion

In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative factors. Here’s some guidance to help you out.