Novel Device Boosts Feed Rate & Throughput

Feed enhancement unit is aimed at low-bulk density materials.

A new device for compounders offers to boost the feed rate and throughput of low-bulk-density materials. Called Feed Enhancement Technology (FET) and developed by Coperion (U.S. office in Ramsey, N.J.), it was on display at last fall’s K 2010 show in Germany and is retrofittable to existing twin-screw extruders. Typical applications for FET are production of highly filled compounds with talc or calcium carbonate, processing of wood/polymer composites, and production of masterbatches.

According to Paul Andersen, director of process technology at Coperion, compounders have struggled for years with feeding low-bulk-density material into a co-rotating twin-screw extruder. Matters have gotten more complicated with the development of fillers with ever finer particle size (sub-micron in some cases) as well as new generations of reactor-grade resin powders. As bulk density decreases, the materials tend to fluidize more easily. Fluidization lowers the effective bulk density even further and exacerbates feeding issues, Andersen explains.

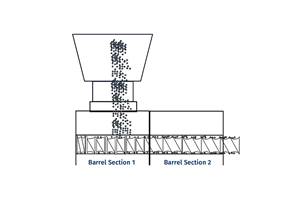

In the FET setup, the feeding zone of an extruder is equipped with a porous, gas-permeable wall section, on which a vacuum is pulled externally. By applying the vacuum through the porous material, air surrounding the polymer or filler is evacuated as it passes the FET barrel-section insert. As the air is sucked toward the insert, it entrains and carries the particles toward the insert surface. The air goes through but the material remains behind to coat the surface.

This coating, or “filter cake,” of densified resin powder has the effect of increasing the coefficient of friction between the wall surface and the bulk of the material. The layer of material adhering to the barrel wall due to the vacuum is continuously renewed by the rotating screws. Additionally, the bulk density of the powder is increased as it passes the insert and is deaerated. These two effects combine to improve conveying efficiency.

There are several options for locating the FET insert. It can be installed upstream of the feed throat and be used as a back vent for pellet feedstocks. It can be installed downstream of the feeding point but before the melting section. Or, to accommodate use of the technology for introducing filler in the downstream portion of the extruder, the FET insert can be installed in the barrel of a side feeder.

Coperion has tested the all three system setup variations on the FET. The downstream configuration (FET insert placed in the main extruder barrel section downstream of the main feed location) was evaluated for an HDPE powder resin. This was first run in the lab, and the system then was installed on a ZSK 240 production unit. The result was that the throughput rate was increased from 14 tons/hr to 17 tons/hr, limited only by the maximum torque of the extruder.

The back-vent version (FET insert placed in the main extruder barrel section upstream of the main feed location) was tested in the lab and then was installed on a 92-mm production line for a halogen-free flame-retardant material. The upstream feed was a blend of polymer, alumina trihydrate (ATH), and additives fed into barrel section 2. Additional components, including oil and a second portion of ATH, were introduced in the downstream portion of the line. The result was a rate increase of more than 50% from 1.4 tons/hr to more than 2.2 tons/hr.

The most typical use for the device is to enhance productivity with highly mineral-filled compounds. For these materials, the most common FET setup is to install the device in the side feeder. Several tests were run by Coperion in this configuration. In one, a 40-mm twin-screw compounded nylon 6 with fillers—either 60% talc (0.25 g/cc), 43% halogen-free flame retardant (0.20 g/cc), or 50% graphite (0.08 g/cc). Rates increased in all three cases, as much as 250% for the talc formulation.

Andersen presented a paper on FET at the recent SPE ANTEC in Boston.

Related Content

How to Configure Your Twin-Screw Extruder: Part 3

The melting mechanism in a twin-screw extruder is quite different from that of a single screw. Design of the melting section affects how the material is melted, as well as melt temperature and quality.

Read MoreHow to Configure Your Twin-Screw Barrel Layout

In twin-screw compounding, most engineers recognize the benefits of being able to configure screw elements. Here’s what you need to know about sequencing barrel sections.

Read MoreHow to Configure Your Twin-Screw Extruder -- Part 2

Follow these tips to configure your twin-screw elements to promote feeding and solids conveying.

Read MoreWhat to Know About Your Materials When Choosing a Feeder

Feeder performance is crucial to operating extrusion and compounding lines. And consistent, reliable feeding depends in large part on selecting a feeder compatible with the materials and additives you intend to process. Follow these tips to analyze your feeder requirements.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More