Productivity and Flexibility in Molding, Extrusion/Compounding, Thermoforming

More quality output in less time, more uptime/less downtime for maintenance and changeovers, and ability to make a wider range of products with a given capital investment—those imperatives are driving innovation at NPE2018.

“The Need for Speed”—plastics processors feel it, for sure; but today they feel the need for faster production of quality product even more urgently. And since no product gets made while a machine is waiting for maintenance or a job changeover, maximizing uptime is part of what keeps them in business. Add to that one more essential for competitiveness: flexibility to produce a wider range of products from their capital equipment.

One goal for makers of all-electric injection presses is to match the speed of accumulator-assisted hydraulics for high-speed packaging and cap molding.

That constellation of needs is what will be driving processors through the doors of the Orange County Convention Center in Orlando, Fla., on May 7-11 for NPE2018. There they will encounter new and upgraded machine models, innovations in controls and automation, new aids to preventive maintenance, and novel approaches to tooling and processing methods. Here’s an overview of what’s in store for injection molders, extrusion processors, compounders, blow molders, and thermoformers.

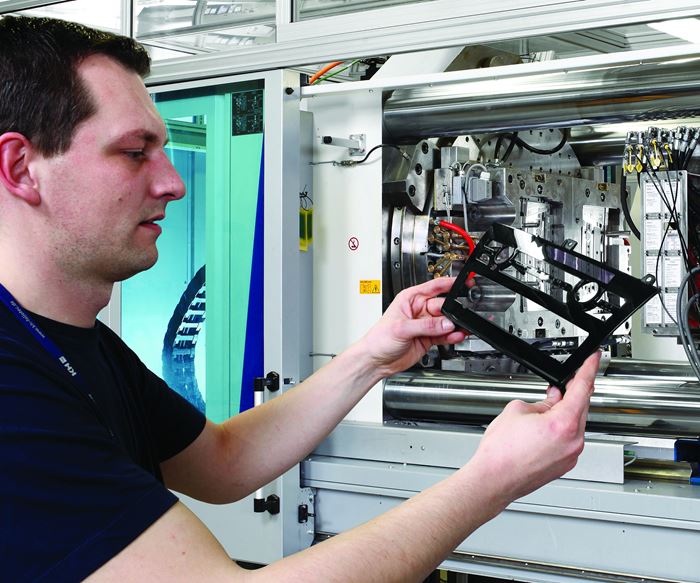

What to Look for in Injection Molding

When it comes to raw speed, injection machine builders have been pushing the benchmark for show-floor molding demonstrations ever lower, so that it ever more frequently approaches—or exceeds—2-sec cycles. Even a 715-ton (650-metric-ton) press today can be capable of 2.4-sec dry cycles.

A special goal for injection-machine designers has been all-electric presses that can compete with accumulator-assisted hydraulics in high-speed packaging and cap molding. Some suppliers have engineered dedicated systems for caps or PET preforms, using closer integration of the machine and mold to overlap motions and wring every possible fraction of a second from the cycle time.

Much of the search for speed has focused on clamp designs, but improved screw designs have also gained fresh attention of late. Other tools for cracking the limits of cycle time include use of rotating “cube” type stack molds that permit cooling to occur in one or two of the four faces. For specialty molding, such as lightweight, high-strength composites, faster preheating of composite organosheets is helping to make this emerging technology even more attractive to automotive and computer/electronics OEMs. Rapid heat/cool, or variotherm, molding is likely to make multiple appearances at the show, where it will demonstrate potential for enhancing both speed and part quality. (Quality, in this case, means more than surface appearance or mold definition—it also means the potential for “erasing” weld lines and minimizing frozen-in stresses.)

Speed-plus-quality will be the theme behind a number of recent developments in molding process-control software that automatically adjusts injection parameters for changes in material viscosity; finds the minimum necessary clamp force to avoid over-stressing parts and molds; and determines the appropriate coolant flow in mold circuits to achieve optimal heat removal without overdoing the cooling and wasting energy.

And be on the lookout for other developments aimed at filling in two of the biggest blanks in the picture of injection molding process control—accurate monitoring and control of melt temperature in the barrel and of mold cooling in individual flow circuits.

Quality, even more than speed, is the focus of special systems for micromolding. Two-stage systems with a fixed plasticating screw and reciprocating screw or plunger claim the advantage of eliminating the nonreturn valve, so that shot size is volumetrically certain and repeatable.

To keep machines running with the least possible downtime, a powerful tool that is offered by more and more machine builders is remote service capability. Also likely to prove important, though still in its early stages, is a movement toward predictive maintenance through new approaches to “condition monitoring” with on-machine sensors for vibration, torque, temperature, and other variables. The goal is to all but eliminate unplanned downtime. Some machinery OEMs are developing ways to monitor the health of ballscrews, electrical systems, clamps, injection units, etc., and even to measure screw/barrel wear without having to pull the screw for a conventional check.

Versatility on Display

Being able to do more in one machine and mold has been a consistent theme of advances in injection molding for the past decade or more. Multi-material molding and integrated multi-process cells have starred at recent major plastics shows and are apt do so again in Orlando two months from now. Molding parts with multiple colors, hard and soft-touch components, and combinations of thermoplastic and thermoset—liquid silicone rubber (LSR) or liquid urethane coatings—demonstrates to processors how eliminate costs of assembly or other secondary operations. (In-mold decorating or labeling are related themes that will get plenty of play at NPE2018.) As noted above, rotating “cube” stack molds have proved a powerful tool for combining materials and in-mold assembly operations in an integrated process.

For molders who have difficulty justifying the cost of a multi-barrel injection machine, an increasingly popular approach is to convert a standard machine—perhaps only temporarily—with auxiliary add-on injection units that sit on the floor beside the clamp or mount vertically on a platen. The variety and capabilities of such units has steadily expanded to include all-electric versions and the ability to add LSR capability to a standard machine.

Interest in foam injection molding is also growing trend, machine builders report, and some newer developments add versatility by allowing for physical foam molding on a standard machine with little or no modification (see PT, Dec. ’15 Fakuma Close-Up).

For some machine builders at NPE, versatility and flexibility have become a strategy of basic machine design. Whole lines of presses are now based on the concept of modularity to enable a range of customization more affordably than in the past. There have also been developments in clamp design that pack more punch in a smaller footprint. As you’ll see at NPE, space-saving two-platen presses have proliferated up and down the size range; but keep your eyes peeled for innovations that enhance the specs of toggle clamps without increasing their size.

What to Look for in Extrusion/Compounding

It used to be that extrusion processors had a choice between dedicated, high-speed lines or systems where material recipes and product structures could be changed quickly. Now, those distinctions are gone: Speed and flexibility are no longer mutually exclusive as machine builders design systems that can accommodate a range of products in a single footprint. And quality is a given.

In blown film, particularly, orders are getting smaller and smaller; which means the quicker a processor can shift from one to the next, the better. Systems are being engineered for lightning-quick product changeovers that permit blown-film processors to make complete format changes—material, color, thickness, layflat width, web tension, blow-up ratio, etc.—in a couple of minutes. Highly complex, multi-layer blown-film lines are also being built to provide processors with unparalleled flexibility, permitting them to mix and match layers and materials in a wide variety of combinations.

None of this flexibility comes at the expense of throughput. In blown film, you can expect to see at NPE2018 more advances in internal bubble cooling and air-ring technologies aimed at increasing rate.

In sheet, “no-dry” systems for running hygroscopic materials such as PET and PLA continue to proliferate. While these lines are aimed primarily at packaging, where volumes tend to be high, flexibility again rules the day, as these lines are being engineered to switch quickly among PET, PLA, and PP.

In pipe, profile, and tubing, recent advances have focused on tooling. Again, the emphasis is on flexibility, more specifically on technology aimed at giving processors the ability to change dimensional sizes on the fly. Look for that theme to continue in Orlando.

Production runs in compounding are getting shorter too, and builders of extruders and pelletizing systems have been focusing on engineering new equipment that facilitates product changeovers by providing easy access to components that need to be regularly cleaned and maintained.

What to Look for in Blow Molding

Their penetration has been gradual, but all-electric shuttle machines seem to be finally catching on with U.S. blow molders, as they already have in Europe and Asia. So expect to see all-electric models featured in Orlando. While machine builders are quick to tout these machines’ energy savings, the bigger draws here are faster cycles, greater output in a smaller footprint, quicker setup and return to production of good bottles after a shutdown, and greater precision and repeatability.

The same arguments are said to be gaining ground with U.S. injection-blow molders, but energy savings and productivity benefits are also said to be available from servo-hydraulic models.

In PET stretch-blow machines, there are also a number of all-electric and servo-hydraulic choices on the market. But the emphasis here has been more on versatility, meaning ability to produce a wider range of complex and “difficult” shapes—bottles with deep pinch grips, tiny necks (2-5 mm on 5-ml eyedrop containers), off-center necks and gates, and very flat shoulders. Also new are machines that make dual-blow heat setting possible on one-stage as well as two-stage PET systems.

And in quality-boosting technologies, be on the lookout for new control and monitoring systems for PET containers that enable processors to optimize crystallinity for maximum strength without sacrificing clarity.

What to Look for in Thermoforming

While the thermoforming market is divided between packaging and industrial applications, exhibitors at trade shows like NPE and K tend to focus on the former. Lines have been showcased that can form an unprecedented range of materials at unheard of speeds (more than 50 cycles/min in the case of PP cups, for example). There’s seemingly no end in sight where the need for speed in concerned, so at NPE2018 you can expect to see more machine builders debuting technologies aimed at increasing productivity.

IML technology figures to be a focus in thermoforming as well. While IML is far more established in injection molding, more formers are eyeing this technology as a means of differentiating themselves from the competition, so machine builders figure to emphasize new options in this area in Orlando.

Related Content

Real-Time Production Monitoring as Automation

As an injection molder, Windmill Plastics sought an economical production monitoring system that could help it keep tabs on its shop floor. It’s now selling the “very focused” digital supervisor it created, automating many formerly manual tasks.

Read MoreAI: The Next Big Thing in Plastics Processing

Discover how artifical intelligence is revolutionizing plastics processing. Hear from industry experts on the future impact of AI on your operations and envision a fully interconnected plant.

Read MoreBASF Highlighting How They 'Make, Use and Recycle Future Solutions'

NPE2024: BASF is using its proprietary computer-aided engineering tool Ultrasim when designing for sustainability in a broad range of industries.

Read MoreFor Extrusion and Injection-Blow Molders, Numerous Upgrades in Machines and Services

Uniloy is revising its machinery lines across the board and strengthening after-sales services in tooling maintenance, spare parts and tech service.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More