In addition to combining utilities that you might expect to be co-located, like blending and feeding or drying and conveying, auxiliaries debuting at NPE2018 combine elements that heretofore have not shared the same housing, like process cooling and resin drying.

As reported in our March Close Up, Novatec and Advantage Engineering collaborated to create the DryTemp+, a patent-pending machine that combines a portable desiccant-wheel dryer and a fluid temperature-control unit (TCU) in a single footprint. The product is aimed at processors that don’t dry centrally.

The unit features a 7-in. touchscreen Siemens pendant PLC, which accesses both drying and mold-temperature-control parameters. The PLC can provide trending and data logging and will be Ethernet equipped so it can be used for QC logging of jobs with resin, mold temperature, and drying parameters recorded. The DryTemp+ dryer is a NovaWheel desiccant dryer sized for 25 to 150 lb/hr, featuring Novatec’s over-dry protection. The TCU comes with one or two circuits, a display screen, capacity of 30 gpm at 30 psi and 30 to 250 F temperature capability.

While a desiccant-wheel dryer normally requires a water utility for cooling, Conair is launching a new generation of Carousel desiccant-wheel dryers featuring an air-to-air after-cooling option. That now frees up these dryers to be moved anywhere in a plant because they are self-contained without a water connection.

The air-to-air aftercooling option reduces the temperature of return air from the drying hopper, improving the moisture-absorption efficiency of the desiccant. Conair’s Carousel PlusX series portable dryers and dX series mobile drying/conveying systems represent a complete redesign of Conair’s Carousel Plus desiccant-wheel dryer and its former W series and MDCW series mobile drying/conveying systems for 15 to 400 lb/hr.

Processors can specify dryers equipped with either an optional air-to-water aftercooler or the new air-to-air aftercooler. The air-to-air unit can sustain drying efficiency while handling return-air temperatures of up to 375 F and dewpoints of -40 F. At the same time, it saves water, maximizes dryer portability, and makes installation and setup faster and easier.

MORE FUNCTIONS, MORE MOBILITY

Mobility and combined functions—drying and conveying—are also the emphasis for Motan with its new line of mobile dehumidifying dryers for small throughputs or stand-alone applications. The Luxor E A and Luxor EM A dryers provide 60 to 150 liters of drying-hopper volume.

Luxor E A models can be integrated into existing conveying systems or equipped with a stand-alone material loader. Luxor EM A dryers with integrated conveying are self-contained mobile units.

As standard, they have integrated drying and a side-channel blower, as well as a small, monitored cyclone dust-collection filter and bin. The Luxor EM A can control up to three Metro-G material loaders—one to supply the drying hopper and up to two more to supply processing machines. Optionally, Metro-G loaders can be equipped with a Metromix proportioning valve, so that any regrind produced at the machine can be immediately returned to the production process.

The dryers operate in a closed process in combination with temperature-controlled regeneration, or there’s an option for dewpoint-controlled regeneration. Both dryer ranges have the new LuxornetEM color touchscreen control.

LuxornetEM controls drying and conveying for three material loaders, as well as recipe management, quality-assurance reporting, and enhanced service functions and trend charts. A weekly timer is also integrated.

INDUSTRY 4.0 MEETS RESIN DRYING

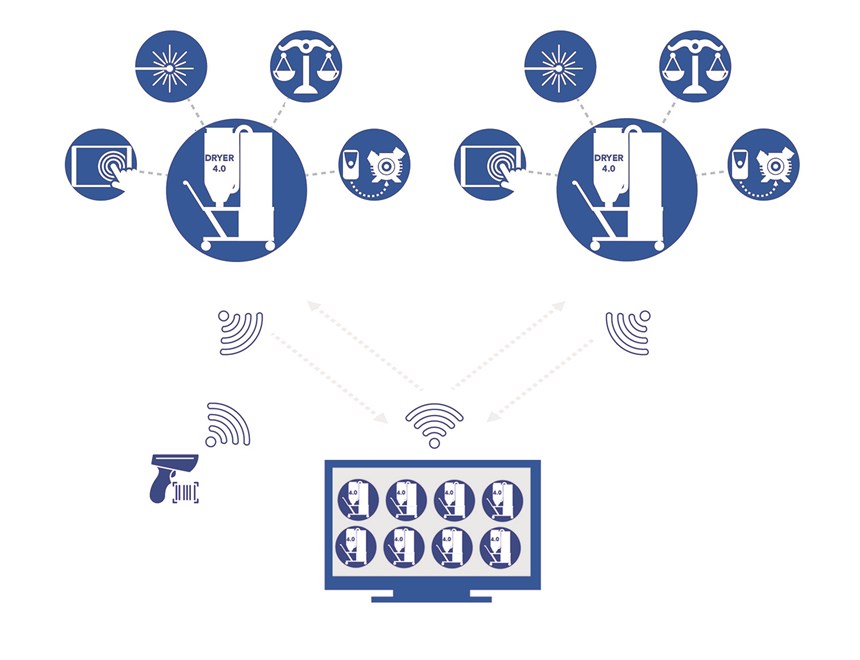

Dri-Air Industries is tapping into Industry 4.0 buzz at NPE2018, launching the Dri-Air Dryer 4.0. Dri-Air says the new line adjusts to conditions and changes in the operation autonomously, gathering information and adapting on its own.

Connectivity is part of Dri-Air’s 4.0 initiative, and for customers with multiple systems, a central dryer control can be installed in a convenient location displaying each dryer’s operating parameters and other important data. When a dryer needs servicing, an icon flashes showing what needs to be done, with directions for service and the parts required. The dryer’s control monitors motor performance, reporting this data to the main control.

As a new Dri-Air 4.0 dryer is installed, it is automatically added to the group display, and the list of spare parts required is updated. An inventory package that tracks and stores the spare parts is under development.

Wittmann Battenfeld’s theme for NPE2018 is Pathways to 4.0 and one of the pieces of equipment on that path will be its new Aton H beside-the-press segmented-wheel dryer, which it describes as being “fully integrated with 4.0 capabilities.” Wittmann Battenfeld says this is its first display of a 4.0-functional dryer.

In a “Wittmann 4.0” connected work cell, when a new mold starts up, all the equipment in the cell, including this new connected dryer, pulls up that part’s setup recipe. The values are saved so operators don’t have to go around to each piece of equipment and set up the TCU, dryer, robot, etc. Everything is controlled through the machine interface. Two Aton H dryers will be involved in active molding machine cells at the company’s booth.

Collecting and sharing data are an integral part of Industry 4.0 connectivity and Maguire Products will showcase an energy-monitoring capability on the newest member of its VBD line of vacuum dryers. The VBD-600 intermediate-range model has 600 lb/hr of drying capacity. The energy monitoring will be displayed on a new touchscreen controller.

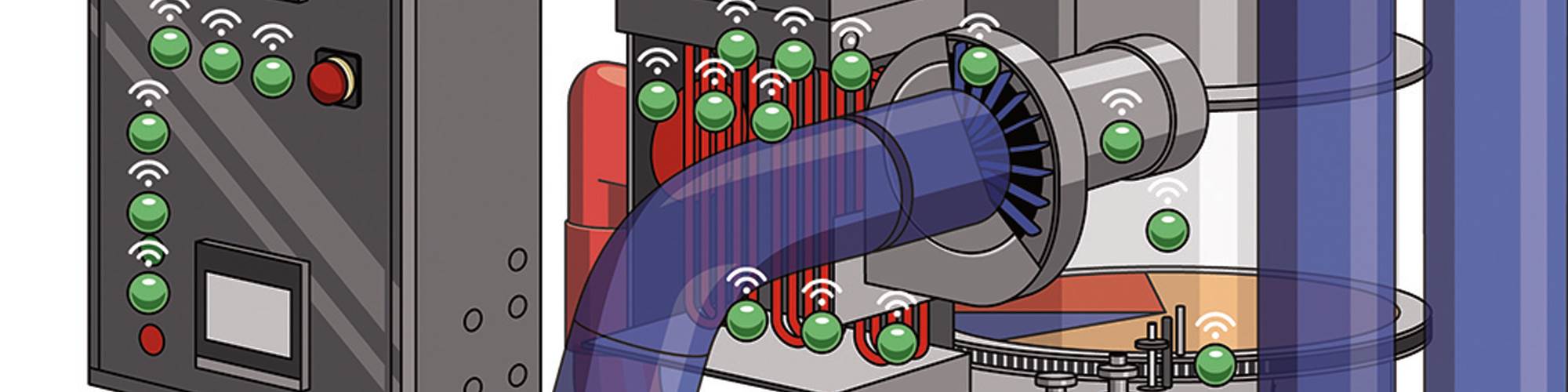

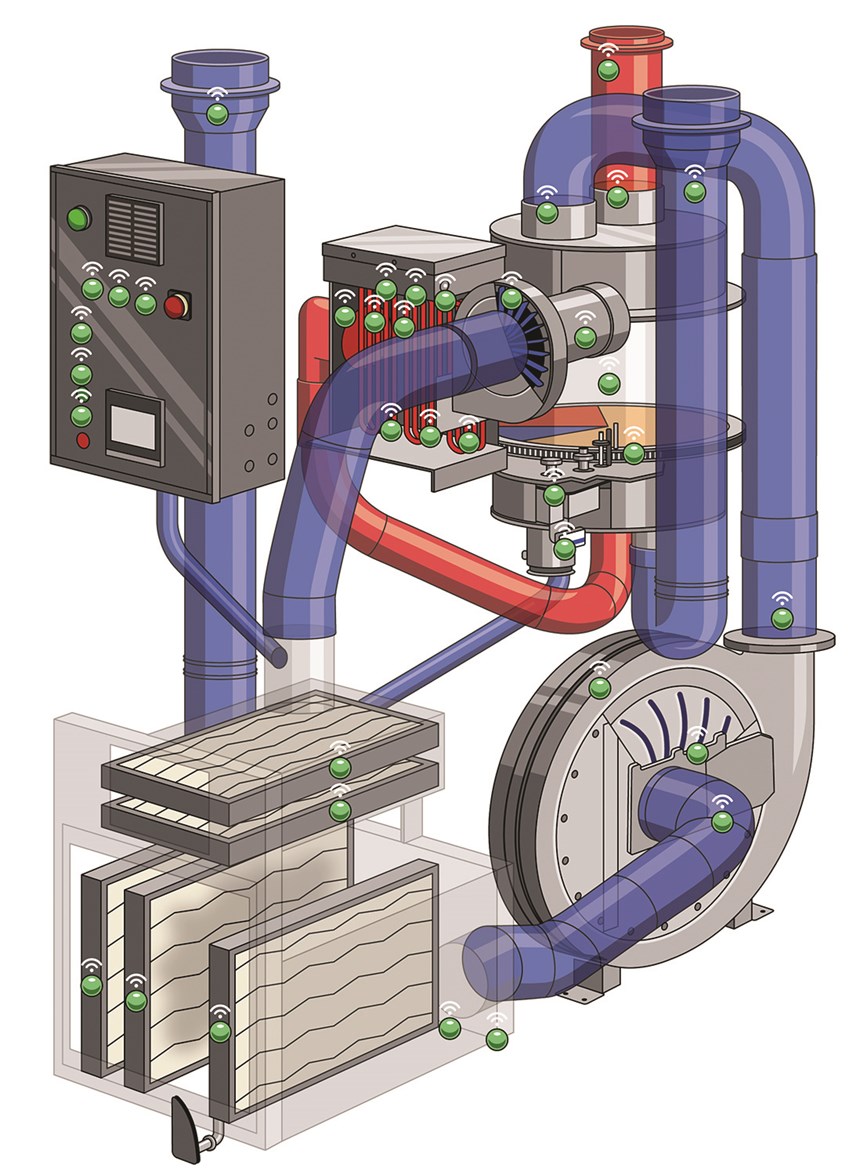

Novatec will take collection and sharing of data a step further with the debut of DigiTwin, a virtual electronic twin of a physical machine that measures and follows every behavior of the physical machine and every key component. The key here is that it is not culling data from the machine-controller PLC, but directly from the multiple sensors located throughout the machine. Novatec calls DigiTwin the ultimate component and machine monitoring system that observes, tracks and predicts performance. At its booth, Novatec will show a physical dryer side by side with the digital model of that same machine next to it. Novatec compares DigiTwin to a “virtual x-ray or MRI” for the dryer, looking under the sheet metal and within the machine for its actual status.

Novatec is also highlighting a new at-the-press drying product for molders tackling highly tailored nylons and other specialty materials. These specially equipped NovaWheel portable dryers have adapted two technologies established in Novatec’s central drying offerings—Moisture Manager and OverDry Protection (see February Close Up).

Also on the 4.0 front, Piovan will introduce FACS 4.0, an auxiliary-equipment control and monitoring system designed by Una-Dyn and based on Winfactory 4.0, Piovan’s OPC-UA compliant supervisory software.

MATERIAL BLENDING, LOADING, DOSING

Consistent with the theme of more functionality from the same footprint, Maguire is introducing a compact system that combines loading, dosing, mixing and dispensing. The Micro Tower mixes up to three materials—such as virgin resin, regrind, and masterbatch—in 10-lb batches. Throughputs range up to 100 lb/hr for the compact tower, which mounts at the throat of the processing machine, with no floor space required for a vacuum pump. The loader and hoppers operate on a loss-in-weight basis under simultaneous direction by the controller for greater accuracy.

Mobility and flexibility are key to the latest iteration of Plastrac’s cart-based blending systems, which are designed to be shared among multiple stand-alone processing machines.

This new line can make additive changes, for instance, faster and simpler, particularly for shops handling short production runs. Plastrac had supplied custom single-cart systems for years, before standardizing the offering and formally introducing it at NPE2015. The new cart systems are duplex and fully independent dual models. In the duplex-dual design, a single virgin feeder and two different color feeders have a shared controller and blower system, operating independently with either manual color filling or an automated color loader. The dual system can manage two different resins for double-shot machines; Plastrac notes that separate hoppers facilitate easy color changes, with a full dual able to accommodate two natural resins and up to two additives, using a shared blower system, with a control box that can manage up to six disc feeders, allowing operators to switch colors electronically.

New to the system at NPE2018 is a touchscreen control. The control offers a full virtual keyboard for recipe entry, while a USB port allows those recipes to be transferred to and from a thumb drive or software updates to be uploaded. The controller features wired Ethernet and allows setup parameters to be stored for later use.

Advanced Blending Solutions (ABS) is introducing its first automated, self-cleaning blender. The Chameleon Simplicity 3000 is a fully automated material-cleanout system that can complete a blender material change without operator assistance. Material is removed from the feeder tray using an automated vacuum system. From there it can be sent to a collection station or bin for later use. Compressed air then cleans the side walls of the component hopper.

Piovan is promoting its line of Quantum batch blenders, entirely U.S.-made, saying it has expanded the range to cover applications requiring a high degree of accuracy. These work in conjunction with its Easylink automatic coupling stations and Pureflo filterless receivers.

Moretto is introducing a self-contained loader equipped with a single-phase vacuum unit, specifically tailored for North American custom processors. The Loader F24 offers high capacity (660 lb/hr) and features stainless-steel construction. Equipped with a wide signal lamp and a die-cast aluminum flange, the units have soft start, fabric filter, and automatic filter cleaning included as standard.

RESIN CONVEYING

Options for moving materials to blenders and processing equipment are also getting smarter at NPE2018. Motan’s MetroConnect U/C manually operated coupling system for pneumatic conveying lines offers an RFID option for error-free connections. MetroConnect C (for “coded”) represents an RFID enabled system. Motan notes that an uncoded MetroConnect U or legacy system (Motan or otherwise) can have the RFID capability added. Motan says that coded coupling stations not only prevent coupling errors, but in certain fields, they are necessary if material tracking, validation or certification is required.

The coupling system is controlled, monitored and configured with the MetroConnect controls. Up to eight blower lines can be set up with a maximum of 96 loaders and material sources. Up to 125 coupling points can be connected to each blower line. If required, an extension of up to 250 coupling points is available.

Maximum flexibility is the goal of a new discrete wired conveying controller that allows the number of pumps and receiver stations to be customized to fit processors’ evolving needs. AEC’s VacTrac Plus can control vacuum receivers, vacuum pumps, remote proportioning valves, purge valves, knife gates, and pump or hopper blowback in any resin conveying application across any process. The control is fully configurable from one to 12 pumps and one to 44 stations.

The VacTrac Plus has a 7-in. color touchscreen, powered by an Allen-Bradley PLC. The graphical user interface with a VNC server allows remote two-way communication on any PC, tablet or mobile device. The system offers Ethernet connectivity and can be networked to PCs anywhere.

Schenck Process will unveil a newly designed Plug Single Tunnel (PST30) diverter valve at NPE2018. The valve’s new features include internally shim-able positive stops, inflatable pneumatic seals at each port, position indication from the tunnel itself, and external tunnel position indication. Additional features include 145° port-to-port rotation combined with the ability to switch between dilute- or dense-phase conveying. The housing, plug and endplates on the aluminum valve are hard anodized for wear resistance. A pneumatic actuator provides a 4-sec actuation time between ports.

MOVE WHAT YOU WANT, GET RID OF WHAT YOU DON’T

Dust, fines, metals and other contaminants are the target of multiple suppliers at NPE2018. Pelletron will showcase two offerings on that front. Pelletron has completely redesigned its C‐20 DeDuster. The dust-removal system can process up to 100 lb/hr of dry granular material and requires no additional floor space. New features include higher temperature capabilities, from 150 to 185 F. An integrated level sensor is installed in the glass tube hopper and can stop the material flow if needed. And the completely new feeder assembly features variable-speed paddles for finer control of solids feed rate. The system’s flat disc-type filters have more surface area than previous closed‐end cylinder-type filters, easing maintenance.

Pelletron will also introduce a completely new dedusting product based on a patent-pending technology. The company says the HR45 DeDuster’s novel half‐round cone technology allows the system to utilize a smaller air system, reducing the unit’s footprint, initial cost, and operating costs. This new model will ultimately replace the XP45 DeDuster model. The company says the same size range that’s available for the XP series will be developed for the HR in coming years.

The HR45 has an overall capacity of 10,000 lb/hr for materials of average bulk density, including PE, PET, PC, PMMA, and nylon. Pelletron says advantages of the new HR45 DeDuster include 40% less power consumption as well as reduced equipment costs, thanks to smaller filters and cyclones—700 ft3/min vs. 1100 ft3/min.

Bunting Magnetics Co. is introducing a drawer magnet rated for use at up to 350 F. The FF 350 Hi Temp drawer magnet can work with molding machines running at higher temperatures without affecting the unit’s rare-earth magnets, which can be damaged by heat. The Hi Temp FF drawer is typically installed above the molding machine’s feed throat, and resin passes through the drawer to remove ferrous contaminants.

For moving finished parts and assemblies rather than raw materials, Dynamic Conveyor will be presenting a variety of DynaCon conveyor systems. The company says its products permit customization using standard components and a variety of accessories For materials handling, Rechner Sensors will showcase the new Smart Paddle Level Sensor with a stationary electronic paddle and a new electronic design that simplifies installation. It detects a wide range of powders, granules and thin liquids with a dielectric between 2 and 80.

PROCESS COOLING

Efficiency, connectivity and transparency are also key themes in process cooling, with new units applying the most efficient technologies for operations while sharing performance data with users.

Thermal Care is updating its central-chiller control systems with a new technology that continuously calculates the lowest allowable refrigerant pressure for any combination of operating conditions in order to maximize energy savings and provide more stable and smooth refrigerant pressure control, especially under varying load and condenser inlet temperatures.

Called Dynamic Lift, the technology also adds direct control of remote condenser fans or condenser water-regulating valves for added savings. According to Thermal Care, users will see an average 25% reduction in partial-load chiller energy use at a 50 F setpoint.

The company will also focus heavily on improved PLC controls, introducing its new Connex4.0 system, Thermal Care’s Industry 4.0 software. With the new control, users can control and monitor any Thermal Care equipment from any Internet-enabled device.

Wittmann Battenfeld is showing the Tempro Plus D mold-temperature controller (TCU) with new energy-saving SpeedDrive option—a variable-speed pump and the ability to set either motor speed, pump pressure, or differential temperature (ΔT).

Also, its Flowcon Plus unit for monitoring and controlling water temperature and flow in individual mold circuits is now available as a stand-alone unit for use with any brand of injection machine.

Delta T Systems will show its new variable-speed, water-cooled chiller at the booth of thermoforming equipment supplier Irwin Research & Development.

Engel is using NPE2018 as the North American launch of its iQ flow control software. Considered the next step in Engel’s bid to eliminate cooling errors, which the company believes have a disproportionate impact on scrap, iQ flow control builds on the company’s flomo electronic water manifold system and e-flomo, which automatically sets the required flow rate for each temperature control circuit. New iQ flow control software networks the temperature-control unit (TCU), e-flomo, and injection machine together. Based on the measured values determined by e-flomo, iQ flow software controls the TCU’s pump speed on demand. While e-flomo increases the process stability and consequently reduces the risk of rejects, automatic speed adjustment means the temperature control will require substantially less energy.

An essential element of this system is Engel’s new e-temp TCU with variable-speed pump. It is built for Engel by HB-Therm. The entire temperature-control process can be set up, monitored and logged on the Engel press’s CC300 machine control. The control determines the ideal operating point for the temperature-control unit and sets it automatically. The various devices are networked with the press via OPC UA protocol.

Burger & Brown Engineering Inc. says its NPE2018 booth will focus on three main objectives for injection molders: cooling water efficiency, quick mold change, and tooling protection. Its newest items are focused on cooling-water efficiency. These new products use the TracerVM electronics platform. The TracerVM Bluetooth Interface collects, transmits and saves flow and temperature data from up to eight TracerVM Base flowmeters installed in mold-cooling circuits.

TracerVM Base Flowmeters purchased separately can be connected via cable to the TracerVM Bluetooth Interface. The interface wirelessly transmits data to a mobile device up to 20 meters away, and the mobile app can display data from up to 30 interface units at one time. The app can create flow-condition data files, which can be saved onto a USB flash drive to document mold cooling-water conditions for process traceability.

TracerVM can also communicate over an Ethernet connection with a local network. Data Logger PC software, which is included with the interface, displays and stores temperature and flow data.

While saving data files, the software enables customizable visual alerts for low- or high-temperature and flow-rate limits. By installing economical non-display flowmeters in the cooling line instead of flowmeters with individual displays, processors can save money with the TracerVM Bluetooth Interface, according to Burger & Brown.

The TracerVMA with AutoReg is a new automatic flow regulator that automatically adjusts flow rate to the required user-selected volume, regardless of changes in line pressure. This results in a more consistent flow rate with more control over cooling-water conditions in critical molding situations. The electronic control communicates with the valve actuator, which adjusts the valve opening to maintain the correct flow rate. Local or remotely mounted electronic control allows for convenient positioning. Electronic control may be mounted up to 9.5 ft away from the flow sensor and regulator.

Also making a U.S. debut from Piovan’s Aquatech brand of industrial cooling is the Easycool+ line of air- and water-cooled chillers; along with Aryacool, a dry cooler that can meet the needs of various industrial processes; and DigitempEvo, which Piovan describes as its flexible heating/cooling solution.

Frigel’s line of Microgel machine-side chiller/TCUs with digital controls now lets users capture, display and record historical process-cooling energy data. In addition to energy consumption, the Microgel’s digital controls allow processors to review temperatures, pressures and flow rates. All operating data is stored in a historical log and are accessible via touchscreen. Processors can use the information to adjust the unit for specific molding conditions and optimal efficiency.

Thanks to what it calls the most efficient fan technology in the industry, AEC says its new High Efficiency central chiller can deliver users up to 60% in average energy savings. The chiller utilizes electrically commutated (EC) fan motors, which AEC says are more efficient than variable-frequency drives (VFDs) and fan staging across the entire load spectrum. Compared with VFD-controlled compressors, AEC says the High Efficiency central chiller is more efficient and less complex, generating the biggest savings when running between 40% and 80% of capacity.

Through Ethernet communications, the chillers can expand up to 10 modules with individual units ranging in chilling capacity from 20 to 60 tons. This redundancy allows process cooling to continue uninterrupted, virtually eliminating downtime. Chilling capacity can be expanded up to 600 tons by combining 10 modules under the same control. Designed to grow with a processor, the line controls off-tank temperature ranges of 20 to 80 F. The system’s control uses a 10-in. color touchscreen, and the chillers themselves communicate with one another via Ethernet to maintain tank temperatures.

Pass-through communication allows the system to skip a unit that is down, while not interrupting the connection to the rest of the system. If a unit does go down, the others automatically begin compensating to maintain the setpoint temperature. Redundancy is inherent in the chillers, which all boast two compressors.

AEC will also present a “Hybrid” freeze-proof adiabatic cooling system. This technology combines dry-air cooling during the cooler months of the year with fluid cooling during warmer months.

AEC says the Hybrid adiabatic cooling system saves up to 95% in water use annually compared with a traditional cooling tower or a closed-circuit fluid cooler. Pulling outside ambient air across coils to remove heat when outside temperature is cool enough, the system only turns on fine misting nozzles when needed.

In addition to saving water, energy usage can be reduced by up to 86% versus packaged air-cooled chillers, according to AEC. Each fan of the system is cycled on and off to meet the cooling setpoint, using high-efficiency motors. Only the fans that are necessary to meet required temperature are used, which saves energy and also results in quieter operation and reduced fan maintenance. In cooler months, the system functions as a dry-air cooling system, operating a fan motor rather than a chiller compressor motor. A closed glycol loop means less maintenance for the freeze-proof system, reducing the amount of chemicals needed to run while also locking out dirt and dust.

Mokon brings an expanded line of its Iceman SC Series portable chillers to NPE2018, now offering units with cooling capacity up to 50 tons. Mokon says this larger size will allow customers to consider portable units for their cooling needs versus having to jump to larger, immobile central systems. The Iceman SC Series, which utilizes scroll compressors and air- or water-cooled condensers, now ranges in capacity from 0.5 to 50 tons. The fluid temperature range goes from 20 F to 65 F.

TESTING & MEASUREMENT

Elevating the process of materials testing will be the theme of Tinius Olsen’s exhibit with the introduction of new scalable, fully automated robotic systems. According to the company, automation of materials testing is now viable for plastics processors who may have thought they needed a certain production volume to move away from manual testing. The company can deliver dedicated or combination systems that test tension, compression, flexion, or hardness.

A robotic system for materials testing can continue running all day and night, leading to gains against an operator of 59 hours a week, or 127 days over the course of a year. A scalable building block approach allows Tinius Olsen to offer systems from very low-force applications, just a few newtons, to very high-force applications of a thousand kilonewtons or more. They can also use a single specimen-handling system with a robotic handling arm to feed more than one testing machine.

The company also has developed a streamlined design for its MP1200 melt indexer with selectable weights that reportedly makes the process of melt-flow testing a lot easier and quicker.

Zwick USA will introduce the Amsler HIT line of dropweight testers, which feature an energy range of a few joules up to 100,000 joules, supporting tests on specimens as well as components. HIT1100F and HIT2000F units boast rapid changeovers through ergonomic features such as an integrated T-slot platform, which enables flexible fixture positioning to secure components and support a wide range of tests, often at angles smaller or larger than 90º.

The HIT600F tester addresses requirements for instrumented multiaxial puncture tests, according to ISO 6603-2 and ASTM D3763, but also a number of international specifications in the automotive industry that now stipulate slower speeds and call for relatively large drop weights. It also supports compression-after-impact (CAI) tests, Charpy, and Izod tests. Model HIT230F, with velocity of 4.4 m/sec and drop weights between 2 and 23 kg, is suited to puncture tests (ISO 6603-2) and CAI pre-damaging by a variety of standards.

A new series of hardness testers will be launched by Mitutoyo America. The latest additions to the company’s Rockwell hardness testers are the HR-530 (maximum specimen height of 8.46 in. and depth of 5.91 in.) and the HR-530L (specimen height of 15.55 in. and depth of 5.91 in.).

C.W Brabender will show its recently launched Meta Torque Plasti-Corder torque rheometer, which features Allen-Bradley PLC field technology, the RheoLink software program, and RFID self-recognition of attachments (e.g., mixers, extruders).

The latest addition to the MetaVue family of spectrophotometers from X-Rite Inc. (xrite.com) is said to be the first non-contact instrument for industrial applications that combines color imaging with spectrophotometry to characterize today’s most complex materials, including plastics. MetaVue VS3200 is suited to lab or QC operations and offers high versatility and color accuracy for the measurement of plastic samples, liquids, powders and gels.

Konica Minolta Sensing will showcase its recently launched CM-25cG compact, hand-held spectrophotometer with specialized features for automotive interiors. The unit’s circular optical system reportedly achieves the highest accuracy and repeatability levels, especially on textured or structured surfaces, regardless of measurement direction.

WELDING & SEALING

Rinco Ultrasonics USA will launch its new AGM Pro ultrasonic generator designed to be built into automation lines and special-purpose welding machines. The digital, Industry 4.0-capable device is an upgraded version of Rinco’s current AGM ultrasonic generator and is reportedly well suited to semi-automated and automated applications in the automotive and packaging industries. Rinco will also unveil its Electrical Motion ultrasonic welder. Available in 20-kHz and 35-kHz, the new unit is said to move away from traditional pneumatic press systems to electrically driven machines. This system enables users to finely regulate the weld, using precise positioning of the horn, along with the applied welding force to the welding rate.

Emerson’s Branson Ultrasonics Div., will feature the latest addition to the Branson 2000Xc series ultrasonic assembly systems; it reportedly combines a small physical size, precise and consistent welds, and the process-control needs of today’s manufacturing environment. The compact Branson 2000Xc 40-kHz MicroActuator measures only 2.76 in. wide by 25.98 in. high and provides 800W output. It locks in the welding process with electronic settings, hierarchical password protection, and Ethernet connectivity access.

Dukane will highlight its newly introduced rotary infrared (IR) welding system that features multiple heating stations to reduce cycle time. The rotary IR welding system is designed for assemblies within a footprint of 7.87 by 9.84 in. that require a fast cycle. It provides non-contact IR welding and can produce welded assemblies as fast as 8 sec, compared with conventional IR welders that run on 30-40 sec cycles.

Herrmann Ultrasonics will highlight the latest enhancements to its HiQ Vario series of ultrasonic welders, which boast significant reduction in setup and changeover times with features like the quick-change system (QCS), whereby the aligned weld tools can be changed to a new application in under a minute.

ITW Shakeproof will feature its new Wercs Technology for design and manufacturing of threaded fasteners, allowing formation of unique geometries on the thread. Using the Wercs Technology, two new products have been created that increase performance of these fasteners: The BosScrew thread-forming screw for plastics is said to be the only screw specifically designed not to loosen in plastic applications; and GripTide insert, a low-cost steel insert for plastics that reportedly surpasses brass inserts in quality, cost and performance.

DECORATING, PRINTING, FINISHING

A versatile, high-performance, compact corona-treatment system will be showcased by 3DT Systems. PolyDyne Pro reportedly improves the surface tension on numerous materials resistant to printing, adhesive bonding and coating. The unit has multiple feedback devices for precise performance monitoring. Its generator and transformer are said to adapt to many applications, such as 3D plastic parts, cup treating lines, plastic sheets and foam.

Lectro Engineering will introduce the smallest Lectro-Treat open-air plasma surface-treating system. The unit is designed for applications where space is at a premium. The LT 2100VD surface treater is only 38 in. wide by 48 in. long, even smaller than a standard flame treater.

Matthews Marking Systems will exhibit seven marking systems: three laser inscribing units, one drop-on-demand (DOD) unit, and three thermal ink-jet units. All seven systems will be controlled by the company’s MPREIA software.

Apex Machine Co. and its sister companies Desco Machine and Capex Corp. will showcase several of its popular and updated dry-offset printers including the C-400 cylindrical part printer, C-9 vertical syringe printer, DRCP-4 rotary closure printer, C-4000 sidewall printer, and S-11-C strap printer.

Related Content

Ensuring Repeatability: The Key to Effective Injection Molding Automation

One of automation’s key promises is repeatability: the same movement to the same location, time and time again. But to achieve that, all elements involved — robot, machine, EOAT, mold — must be in and stay in alignment.

Read MoreThe Future of Automation in Injection Molding

Are you automating enough? At #PTXPO23 we spoke with leaders in automation and injection molding about the current state of automation and what’s in store for the future.

Read MoreLSR Advances in Dispensing, Tooling and Automation

At Fakuma 2023, Sumitomo (SHI) Demag’s LSR injection molding machines showcased advances from itself and partners Reinhardt-Technik, Rico and Sepro.

Read MoreOpen Automation Enables Flexibility in Chemical Recycling

Software-defined equipment control systems can be duplicated, transferred and scaled with ease.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More