Universal Dynamics Inc.

A Piovan Company

11700 Shannon Drive

Fredericksburg, VA 22408 US

703-490-7000

sales@unadyn.com

unadyn.com

IS THIS YOUR COMPANY?

As Seen On Plastics Technology

Universal Dynamics Inc. Supplies the Following Products

- Blenders (non-intensive)

- Chillers

- Closed-loop Process Control Systems

- Conveying Equipment (pneumatic and Mechanical)

- Dryers for Resins

- Feeders

- Granulators

- Hopper Loaders

- Hoppers, Bins, Tanks

- Level Sensors and Controls

- Metal Detectors, Separators

- Metering, Proportioning Equipment

- Mold Dehumidification Systems

- Semi-bulk Containers

- Silos

- Temperature Controllers, Monitors

- Troubleshooting, Problem Solving Systems

- Vacuum Pumps

Editorial, News, and Products

-

A Coronavirus Comeback Restarts Growth at Medical Compounder

A slowdown in catheter production stopped growth in its tracks last year at Foster. But business has turned around quickly this year, and the medical compounder was prepared for the rebound.

-

K 2019 Report: Auxiliaries Stake Their Claim in the Circular Economy

The theme of sustainable plastics pervaded the exhibits at K 2019, even those of auxiliary equipment suppliers, where everything from dryers to blenders to hopper loaders was reimagined as part of a circular plastics process.

-

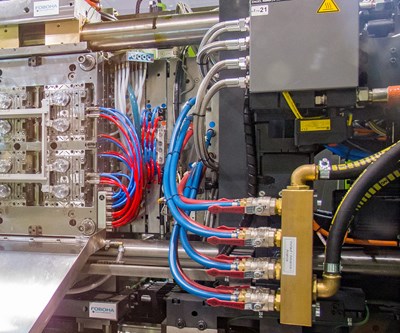

Better Options for Mold Cooling—The ‘Next Frontier’ in Process Control

New concepts in mold temperature-control units, conformal cooling, and more in Tooling & Cooling session at Molding 2019 Conference.

-

Material Handling: News in Conveying & Drying at Fakuma

Piovan introduces filterless receivers, upgraded coupling station, and new drying hoppers.

-

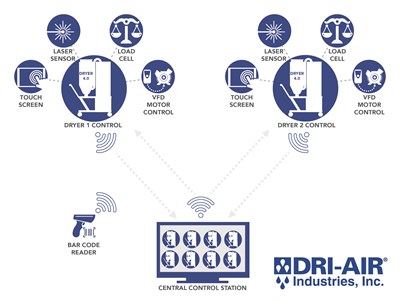

Advanced TCU Controls Both Temperature & Flow Rate

Unlike most TCUs, which control only water temperature, Nextherm controls both temperature and flow rate by means of a positive-displacement gear pump with a variable-frequency drive (VFD).

-

New TCU Ready for Industry 4.0

Easytherm incorporates the OPC-UA communication protocol, making it ready for communication with machines from different suppliers.

-

New U.S. HQ for Piovan and Una-Dyn

Grand Opening will be held in new facility in Fredericksburg, Va., on October 4.

-

NPE2018 Auxiliaries: A Path to Industry 4.0 Emerges

Industry 4.0 dominated the news in auxiliary equipment at the show, but many questions remain for both suppliers and processors.

-

NPE2018 New Technology Focus: Drying

Industry 4.0 meets resin-drying at NPE2018.

-

Practical Application of Industry 4.0 Promoted at Piovan, Una-Dyn

10 years after it acquired Universal Dynamics, Italy’s Piovan Group continues to expand its presence in the North American market as it nears completion of a new plant for Una-Dyn in Fredericksburg, Va.

-

Auxiliaries at NPE2018: Packing More Functions in Less Space

Auxiliary equipment suppliers are building more and more technology into their products, packing more physical and virtual functions into the same or smaller footprints.

-

Optimized Molding Is Possible With Material Drying, Handling

Injection speed and overall cycle time are often the focus for molders pursuing optimized processes, but for truly efficient production, molders should consider how and in what state material arrives at the machine.

-

'Talking’ Machines Pave the Way for Processing Plants of Tomorrow

At the convergence of smarter equipment, open communication protocols, and more powerful networks, a new shop floor emerges where groups of intelligent machines work seamlessly as integrated systems.

-

Auxiliaries AT NPE: New Controls Link Auxiliaries

Industry 4.0—the internet of things—is bringing a new level of connectivity to auxiliary equipment. Here’s a rundown of developments there, along with other news in auxiliaries from the show.

-

Two New Directions for Una-Dyn at NPE

Powder bulk handling and process cooling are two new product lines.

-

AUXILIARIES AT NPE: More Control, Flexibility, And Efficiency

These are key trends in the many kinds of auxiliary equipment displayed at this month’s show. You’ll also see equipment designed to be virtually ‘foolproof.’

-

Resin Conveying: No More ‘Spaghetti Bowl’

You now have technology choices to avoid the maze of conveying tubes that form a ‘spaghetti bowl’ or ‘rat’s nest’ in a central materials-handling system. Here’s how they stack up.

-

Savvy Processors Reveal Best Practices on Drying

The processors speak: Here’s how some smart molders and extruders tackle the vexing problem of resin drying.

-

K 2013: More Efficient, Flexible & User-Friendly Auxiliaries

It’s hard to generalize about auxiliary equipment, but a few trends stood out at K, including: greater energy efficiency, ease of maintenance and cleaning, controls that provide more real-time and historical process information and greater ease of use.

-

Conveying, Drying, Crystallizing PLA : The Energy-Saving Packaging Solution

When the new industry term “bioresins” hit the plastics community in the early 2000s, polylactic acid (PLA ) made its way to the top of the list in a class of new plant-based materials.

-

Making Old Bags New Again

This year, leading film processor and bagmaker Hilex company reprocessed 25 million lb of post-consumer material in its Bag2Bag recycling program.

-

Auxiliaries at NPE: News in Materials Handling, Cooling, Granulating, Welding, Testing, Decorating

Auxiliary equipment takes in a broad range of functions, from materials preparation to post-mold finishing.

-

Thrifty California Processor Dries PET with 'Waste' Heat

Southern California can be a challenging environment for manufacturers, not least because of concerns about the cost and availability of electrical power.

-

Auxiliaries at NPE: New Solutions from Material Preparation To Post-Mold Operations

There will be an extraordinary range of new auxiliary equipment on display at the show.

-

NPE News Wrap-up: Resin Dryers

At least 16 companies introduced new dryers at the big show in Chicago. The new models span a range of drying technologies, but most sport features that save space and cost and make the dryers simpler and more reliable.

-

On-Site: Green Business Is Good Business for Fabri-Kal

Learning to deal with the particular characteristics of PLA biopolymer has opened up a promising business in “green” plastics for thermoformer Fabri-Kal.

-

Materials Handling: New Equipment Emphasizes Efficiency & Value

Visitors to the recent NPE 2009 show in Chicago were looking for materials handling equipment that could do more than dry, blend, or convey resins. It had to do those things while saving energy, providing faster and easier maintenance, speeding product changeovers, reducing labor cost, minimizing waste, and providing better value for money. The new products cited below addressed those needs and more.

-

NPE 2009 News Flash

Injection MoldingHybrid Press Has Electric ClampNew injection presses that combine servo-electric and hydraulic movements to achieve high performance with energy efficiency will be discussed by Arburg Inc., Newington, Conn.

-

Getting Control of Materials Handling

“It has made my life a whole lot easier,” says Steve Holdren, technical manager. “It’s a night-and day difference,” agrees maintenance manager Matt Dzambazi.

-

HOW TO COMPARE DRYERS? A Complex Challenge With No Simple Answers

Is one type of resin dryer faster or more energy-efficient than another? That question prompts competing claims from suppliers—but very little concrete data. When one vendor performed controlled tests to get some answers, its results, published here for the first time, prompted further debate about the difficulties of making valid comparisons and the many complex issues involved in dryer selection.

-

NPE 2006 News Wrap-Up: Materials Handling: A Host of Refinements and Updates

NPE 2006 held no revolutionary changes in dryers, blenders, feeders, loaders, or conveying controls, but widely adopted improvements make the newest models easier to use and maintain—and easier on the budget, too.

-

What to See at NPE 2006: Heating and Cooling

Most of the news at the show is in fluid-circulating mold-temperature-control systems.

-

What to See at NPE 2006: Materials and Parts Handling

Dryers, feeders, blenders, loaders, metal detectors, level sensors, mechanical and pneumatic conveyors, silos, bins, pumps, filters, valves, box fillers, bag dumpers, and materials-handling control systems constitute one of the biggest categories of products on display at NPE.

-

To Catch Trouble Early, Put Your Dryers on the Net

In the past, troubleshooting your resin dryer was a fairly straightforward procedure.

-

Resin Dryers: Which Type Is Right for You?

Processors today face bewildering choices of at least five basic types of dryers, whose capabilities are subject to conflicting claims from equipment suppliers. For the buyer, the most basic questions are: How much drying is needed for the job and which dryer types are up to the task?

-

NPE News Wrap-Up: Materials Handling

The big show in Chicago presented more new loaders, feeders, blenders, and conveying controls than you could count. They’re more flexible, easier to maintain, and easier to control. Many are web-enabled, and some are lower in cost.