NPE2024 Materials: Spotlight on Sustainability with Performance

Across the show, sustainability ruled in new materials technology, from polyolefins and engineering resins to biobased materials.

In its return for the first time in six years this past May, NPE2024 was excellent in terms of plastics manufacturing technology on display, including new materials. Also significant: the fact this event is reported to have been the largest gathering for bioplastics companies in America.

Also noteworthy was the presence of two major polyolefin newcomers: Shell Polymers, which participated in NPE2018, with its broad range of LLDPE and HDPE for all key PE markets; and Heartland Polymers, which began commercial production in 2023, highlighting its broad range of PP resins. Yet another, was the presence of two new global engineering resin entities: Syensqo, the December 2023 spinoff of Solvay Specialty Chemicals, and Envalior, which emerged in April 2023, bringing together the complementary suppliers DSM and Lanxess.

Sustainability, in one way or another, was at the core of nearly all new developments but always with performance attributes and an emphasis on collaborative efforts for a range of resins from polyolefins and engineering resins to biobased materials.

Enhanced and Sustainable Polyolefins

Nearly all the key polyolefin suppliers have been launching and expanding on new, more sustainable resin offerings between the K2022 and NPE2024 shows. Certified circular polymers — generated by mechanical or chemical recycling — with PEs and PPs available from ExxonMobil, SABIC and LyondellBasell, as well as PEs from NOVA Chemicals, Braskem and Dow (PE), were a big part of expanded portfolios. Additional material and design advances were shown, particularly in the packaging arena, which enable less plastic use while offering enhanced performance.

ExxonMobil launched Enable 1617, an ethylene 1-hexene copolymer designed to deliver enhanced processability and films that exhibit superior optical properties such as haze and gloss, particularly in thin-gauge, hand-wrap stretch-film applications. This performance PE delivers improved tenacity for higher load stability and stronger holding force. This resin is said to combine two key and seemingly opposite features — high flow and high tenacity — which result in improved cast film processing, exhibited by faster line speeds, lower pressures and lower motor loads when compared to incumbent high-tenacity grades. The balanced properties provide the opportunity for thinner gauge film and consistent extrusion, which is one of the most important stretch-film qualities. As reported in PT’s July issue, Colines’ AllRollEx line produced high-tenacity hand-wrap film at a thickness of 8 microns containing 35% postconsumer recycled (PCR) material along with Enable 1617.

Enable 1617 combines two seemingly opposite features — high flow and high tenacity — which results in great cast film processing. Source: ExxonMobil

Nova Chemicals highlighted its capital investments to grow its thin-wall injection molding (TWIM) product portfolio, and to reintroduce Surpass IFs730 and IFs932 high-melt index injection molding grades. Both are designed to meet the demands of fast-paced injection molding processes and provide versatility and compatibility when run on different production/conversion lines. Key features include enhanced shear thinning for processability; fast cycle times; antiwarpage properties; and broad food contact and end-use compliance. Nova also undertakes at-line testing of its resins during production to supply consistent, defect-free PE.

Heartland Polymers emphasized the positive engagement it has received in the PP film extrusion market with one of the “highest quality resins” in the nonwoven and thermoforming sectors. The company is also adding random copolymers to its production mix this year, which it positions as well suited for the food and packaging industry.

Structural and insulative properties in blow-molded air ducts for automotive applications have also been demonstrated with PP-UMS. Source: SABIC

A very high melt strength PP that boasts outstanding foamability was highlighted by SABIC in two diverse transportation applications. SABIC’s PP-UMS (polypropylene-ultra melt strength) enables the extrusion of PP foams with very low density, excellent impact resistance and VDA 278 emissions regulations compliance. SABIC PP-UMS foam resins processing versatility enables PP foams, subject to user testing, to be used in structural cores for sandwich panels in delivery vans, trucks and recreational vehicles (RVs), and to provide structural and insulative properties in blow-molded air ducts. Examples of both applications were displayed to illustrate the suitability of this foam resin for broad use in transportation components that can benefit from significant weight reduction and potential cost optimization.

PP-UMS foam resin’s processing versatility enables PP foams, subject to user testing, to be used in structural cores for sandwich panels in delivery vans, trucks and RVs. Source: SABIC

SABIC also highlighted its new Stamax 30YH570 long-glass fiber PP for electric vehicle (EV) batteries by sharing test results that underline the potential of thermoplastic-based thermal runaway barrier solutions to prevent fire spread in EV batteries. The SABIC subsystem level test series showed that a battery module box made from this resin with intercellular thickness as low as 1 mm has the potential to provide the needed thermal insulation and flame resistance to reduce the chances of cell-to-cell propagation in a thermal runaway scenario, mitigating the risks of a catastrophic safety incident.

Range of Engineered Resins

Polymer Resources features an unfilled, impact-modified PBT grade for diverse electrical applications, such as telecom enclosures; electric vehicle charging infrastructure covers; residential and commercial plugs, switches and outdoor enclosures for sprinkler controls; and industrial electrical and cable boxes. The new TP-FR-IM3 PBT is said to deliver a complete array of high-performance properties, including excellent weatherability; high chemical and impact resistance; and flame retardance for outdoor, intermittent outdoor and indoor components like enclosures and housings.

TP-FR-IM3 PBT is said to deliver excellent weatherability; high chemical and impact resistance; and flame retardance for outdoor, intermittent outdoor and indoor components. Source: Polymer Resources

Injection molding TP-FR-IM3 resin has earned all-color certification under UL743C F1, demonstrating UV and water resistance for excellent weatherability. It is also said to boast better chemical resistance than competitive UL F1-certified grades, enabling it to resist degradation from exposure to organic acids, inorganic aqueous salts, alcohols, and mild acid and base solutions, which can lead to stress cracking. It meets both the UL94 V0 and UL94 5VA standards for flame retardance at 1.5 mm (0.06 in.), and provides good mechanical performance, including high impact resistance.

Another high-performance PBT, Valox HX325HP, as previously reported, is a new high-flow medical grade from SABIC developed for the injection molding of high-precision parts used in diabetes management. Included are components of insulin delivery pens, insulin pumps, auto injectors and continuous glucose monitors, where this resin is said to offer outstanding processability with high chemical resistance and validated biocompatibility.

Polymer Resources highlighted its expanded portfolio of sustainable engineering resin compounds, containing at least 50% recycled content, as previously reported. Initial commercial offerings include a low-, medium- and high-flow PC, as well as a PC/ABS. The portfolio has been expanded to include several flame-retardant products listed by Underwriters Laboratories (UL) in natural, black or custom colors.

Syensqo showcased its extended Omnix Echo portfolio of circular nylon 6 and 66 resins, with five new high-performance grades providing mass-balanced allocated recycled content between 33% and 98% from postconsumer and/or postindustrial (PCR/PIR) sources, including fibers. This included food- and nonfood contact grades.

Other new nylons launched included long-chain versions such as 610 and 612 grades from Nylon Corp. of America (NYCOA) as part of the company’s ‘transformation’ into a specialty nylon company, as reported previously. They are suitable for a wide range of processes, including injection molding, extrusion, blow molding and rotomolding.

NYCOA also launched the new NXTamid L family, said to exceed the performance of nylon 11 and 12 in many applications with a broad range of customization options. Also new from NYCOA is the NXTamid L nylon family, said to exceed the performance of nylon 12. Compared to standard nylon 12, NXTamid L features a tunable backbone, higher service temperature and low extractables. It delivers sustainability benefits with a 25-60% biobased composition.

NYCOA has also developed amorphous 6I/6T nylons called NY-Clear, which are said to offer higher temperature resistance, lower moisture absorption and better retention of properties compared to nylons 6 and 66. Intended uses are in flexible food packaging that requires high strength and stiffness, as well as hydrolysis resistance.

Biobased and PUR/PIR Recycled-Content Materials

PHA (polyhydroxyalkanoate) producer CJ Biomaterials introduced Phact S1000P semicrystalline PHA (scPHA), which is TÜV OK-certified for home and industrial composting, as well being a TÜV OK-certified marine and soil biodegradable material.

The company entered the PHA market in 2022 when it introduced Phact A1000P, its amorphous PHA (aPHA) solution. Compared to scPHA and crystalline PHA, aPHA is a softer, more rubbery version of the biopolymer which offers different performance characteristics. The new PHACT S1000P is a more rigid variety of PHA better suited for applications that require high heat stability. It can be processed using various conversion technologies, such as injection molding, thermoforming and extrusion. Phact S1000P is also included on the U.S. FDA Inventory of Effective Food Contact Substances (FCS), joining Phact A1000P. As such, CJ Biomaterials’ aPHA and scPHA can both be used to manufacture food-contacting packaging materials that are sold in the U.S., including rigid and flexible packaging, food service ware and other products.

BASF showcased two mechanically recycled engineering resins for automotive and other applications. Nypel nylon, which can be made from PCR and/or PIR materials, is currently being used to produce air intake manifolds in automotive. Petra thermoplastic polyester, which is based on 100% PCR and PIR PET, is currently used in serial automotive production for large structural parts.

Kraiburg TPE presented both a new line of TPE compounds incorporating PIR and/or PCR materials, and a new line of biobased TPE compounds, tailored for consumer goods, industrial and automotive applications.

The former are PP-based TPE compounds while the latter, Thermolast R, are derived from renewable raw materials that are said to reduce carbon footprint by up to 50% compared to conventional nonrenewable alternatives.

Teknor Apex, exhibiting together with UBQ Materials (the Israeli climate tech developer of advanced materials made from unsorted household waste), highlighted the deepened collaboration of its more than 2-year partnership with Teknor’s expanded development of sustainable TPE compounds containing UBQ materials. The focus is on durable goods, ranging from industrial to consumer applications.

Related Content

At NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

Read MoreBest Practices for Purging PHA and PHA/PLA Blends

Because bioplastics are processed at lower temperatures, purging between jobs requires a different process and purging agents than those applied for traditional resins.

Read MoreHow to Optimize Injection Molding of PHA and PHA/PLA Blends

Here are processing guidelines aimed at both getting the PHA resin into the process without degrading it, and reducing residence time at melt temperatures.

Read MoreHow to Optimize Your Molds and Hot Runners for Processing Bioresins

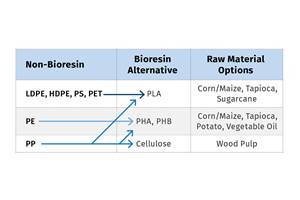

Demand for bioresins is growing in molded goods, particularly as a sustainability play to replace fossil-fuel based materials, but these materials are not a drop-in replacement for traditional materials. Molds and hot runners need to be optimized for these materials.

Read MoreRead Next

At NPE2024, Follow These Megatrends in Materials and Additives

Offerings range from recycled, biobased, biodegradable and monomaterial structures that enhance recyclability to additives that are more efficient, sustainable and safer to use.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreNPE2024 Will Be Largest Gathering of Bioplastics Companies in the Americas

NPE: The Plastics Show, produced by the Plastics Industry Association, features 1.1 million square feet of exhibits, making NPE2024 the biggest plastics show in the Americas.

Read More