Optimize Resin Management in Extrusion Blow Molding

In the EBM process, profits depend greatly on how judiciously you use resin.

“What’s new?” Magazines such as Plastics Technology focus heavily on reporting on new developments in machinery, auxiliary equipment, tooling and materials. While all this is good stuff, the simple truth in extrusion blow molding (EBM) and other plastics processing is that your ability to operate profitability is governed mainly by how judiciously you use resin. To prove this point, take a look at the cost structure of a typical molded part.

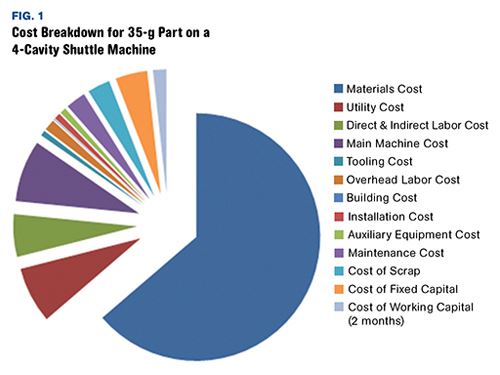

In the scenario in Fig. 1, a four-cavity machine is making a 35-g part in cycle time of 12 sec. Resin accounts for 63.5% of total manufacturing cost. When you add in the costs associated with scrap (this example assumes 4% of the material used in the process is scrap; in reality that percentage is often higher), material-related costs are bumped up to two-thirds of total expenses.

In other words, the money is in the resin. Improvements you may be looking to make in labor or energy are important, but the benefits pale in comparison with savings that can be achieved by optimizing resin usage. This article does not concern itself with resin buying strategies—a different topic of equal importance—but with making the most efficient use of what you have already purchased.

Let’s start by reviewing the basics of the process and relevant terminology. In EBM, plastic pellets are extruded into a hollow tube called a parison. For this purpose, the plastic exits the extrusion head via a male pin (also called a mandrel) and a female die (also called a bushing). The parison is then clamped between two mold-halves and air enters through a blow pin or needle into the cavity, forcing the parison onto the cooled mold walls, where it rapidly solidifies into the desired shape of container. There is always flash at the top and bottom of the container that must be trimmed, ground, and fed back to the extruder as regrind.

Most machines nowadays are equipped with a wall-thickness controller or programmer that moves either the pin or die during extrusion to vary the thickness of the parison. This programmer may use 20 to 400 points to control parison thickness during extrusion.

As a result, material can be distributed to various container sections that require different amounts of plastic in a more uniform way. Bottle shoulders, for example, always need less material than bottle bodies, and this can easily accomplished by using the programmer. For the programmer to work properly it is critically important that the length of the parison is always the same and that all parisons in a multi-cavity setup are of the same length. This is true because the programmed thin and thick spots must end up precisely in the container sections they are destined for, and varying parison length will move these spots up or down.

Virgin plastic, regrind, and possibly color must be mixed and supplied at precise rates. This is especially important for color additives, which tend to be expensive. Older systems used time-dependent feeding of virgin and regrind, and feed screws driven by DC motors for color. This system can lead to layering of the virgin and resin, which in turn can result in extruder surging.

A better approach is to deploy a gravimetric material feeding system that weighs each lot of material before dispensing. Many molders do use these systems, but unfortunately many of them are not calibrated properly and are therefore not delivering consistent batch amounts. This is often due to the fact that material handlers are not aware of the importance of proper calibration or are not trained to perform it.

Another complication arises from the fact that regrind levels are usually not constant. During startup, and when adjustments become necessary during a production run, inadequate bottles are thrown onto the flash conveyor and reground. This increases the amount of regrind and fills bins up rapidly. Material handlers that have not been instructed otherwise then routinely increase the regrind percentage on the material feeding systems dramatically to work off the excess regrind.

However, regrind processes differently, and the result of increased regrind percentages is longer and wider parisons. The longer parisons change the positions of important program points and the result can be containers that are out of specification. Savvy operators are well aware of this fact and program their parisons accordingly by stretching thick parison sections over more points of the program than necessary. This way, they will still make a sellable part even with a different parison length. The bad news is that the parts will be heavier than they need to be. And that’s money down the drain.

So how do you get better at efficient resin consumption? Here are six quick thoughts:

•Tip 1: Train material handlers in how to calibrate gravimetric feeding systems and establish procedures to deal with increases in regrind. Tape a piece of tail flash with the proper length to the safety gate so an operator can check quickly whether the parison length is what it should be.

Many operators give up too early in adjusting parison length when it comes to multi-cavity systems. To get all four, eight, or 12 parisons extruding out of a head to the same length requires skill and patience. Small mechanical adjustments are necessary, and each requires stopping the machine. Operators are generally reluctant to halt production. For very short runs it may not be suitable to spend too much time on parison length, but every run over one week long should be considered deserving of this care.

•Tip 2: Allow setup personnel time to properly adjust parison length when warranted, and have them tighten up thick sections in the extrusion program.

•Tip 3: Review programmer needs and plant equipment and replace inadequate programmers. In order to put material where it is needed in the container, the programmer must be responsive and allow good control over the parison. Unfortunately, may companies still run programmers that offer only 20 or 25 programming points per extrusion cycle. While this is sufficient for the short parison of a 20-oz bottle, sizes above 32 oz would do better with 64 programming points. A parison 2-ft long (or more) should be programmed with at least 100 points (programmers with up to 400 points are available now).

Only with sufficient programming points is it possible to direct material effectively into container areas that need it. The servo valves that control the movement of the hydraulic cylinders for programming also must be responsive enough to follow sharp program transitions. All too often, a servo valve comes under scrutiny only when it fails. Have setup personnel adjust servo-valve gains regularly, at least monthly. This important procedure takes less than 5 min.

There are additional options if you’re molding oblong bottles. Either the pin or die may be ovalized (with the die being the preferred choice). This may be necessary to add strength to corners or to avoid thick ribs across the panel area of a flat oval container. This is usually accomplished by scalloping out parts of the die in some specified fashion to allow plastic to flow into these areas.

Blow molders benefit greatly if they have this capability in-house rather than buying ovalized tooling from outside. That is because more often than not small adjustments can be made only after an initial run and many processors hesitate to send tools out for rework because of the ensuing production delays. As a result, insufficiently ovalized tools lead to weight settings higher than would be necessary had personnel gone the extra mile. That leads us directly to our next tip.

•Tip 4: Build die ovalization expertise in-house and strive to perfect tools before going into production. The situation is different for processors and brand owners. The latter have the highest interest in lowest-weight containers, as it directly affects the price they pay for the package. The challenge is the same whether production is in-house or through a supplier. Smaller companies can learn from large groups and develop their own sets of testing procedures that adequately reflect the product life cycle.

All too often assumptions are made about what top load the container must have or what drop test conditions are adequate. It takes a closer look at what the container is exposed to in the distribution chain and at the consumer to come up with testing regimens that will give a high confidence level that the product will not fail.

Because EBM allows lightweighing without adding much cost, long-term tests can be made while in production, with some sort of safety margin built into the container. If it turns out that a lighter container will do the job, this can be implemented at any time. Engineers should know that the brimful capacity of the container will most likely go up, not just because of thinner container walls but because these thinner walls bulge out more after filling. It is therefore recommended to run initial containers at the lower end of the capacity tolerance.

Tip 5: For brand owners, because some testing involves long-term procedures, manufacture initial containers with a wider safety margin to speed up time to market. Run lower-weight samples and test them during production. Reduce weight when testing shows that lower-weight containers will perform.

The situation is a bit different for molders. They are usually given a weight specification with a tolerance. Let’s say a container may be run at 27 g with a tolerance of ±1.5 g. Very often there is also a minimum wall thickness specified, usually for the bottom corner.

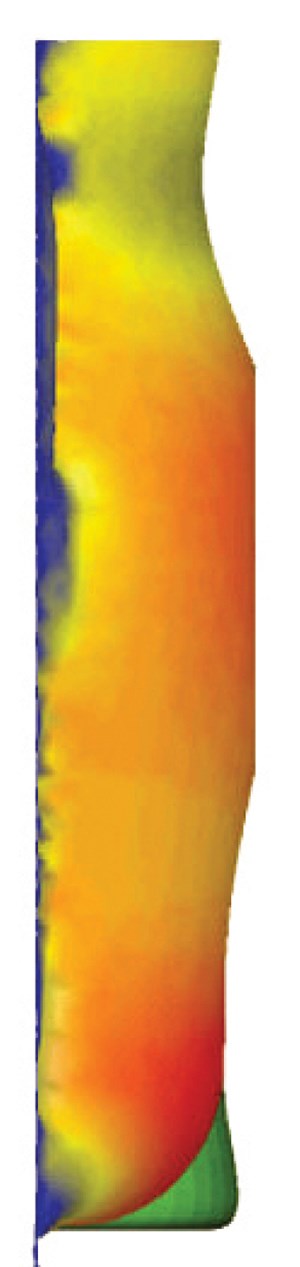

In the computer simulation in Fig. 2, the mold is green and the parison is yellow, orange, and red depending on wall thickness (with red being the thinnest). This simulation clearly shows that the parison has to travel the longest to reach the bottom corner, making this part the thinnest, thus requiring the most attention during programming.

Because operators do not like to have their production quarantined by quality control for insufficient wall thickness, their tendency is to run the container in this example at 27.5 to 28.5 g. However, if they had followed the suggestions above they might be comfortable in running it at 26.5 to 27.5 g and save about 1 g of material. One gram of material savings on the 9 million containers the shuttle machine in our cost example can produce translates into savings of almost $16,000/yr, assuming resin price of 80¢/lb.

Tip 6: Implement all other suggestions and run suitable product tightly around the target weight for additional savings. Tightening up on machine functions with new programmers and properly adjusted material feeders results in more consistent container dimensions, weights, and test results. The ability to run containers with parameter values that gather tightly around the target values translates into a higher process-capability factor (Cpk value) when the numbers are run through statistical analysis. Large brand owners tend to want to do more business with companies that can provide these numbers.

About the Author

Ottmar Brandau is principal of Apex Container Tech Inc., Wasaga Beach, Ont., a consulting company that specializes in design and manufacturing for EBM and stretch-blow molding. Apex is involved in operator/engineer training, product development, plant audits and improvement programs, process troubleshooting, and new plant layouts and startups. Contact: (705) 429-1492; e-mail: info@blowmolding.org, website: blowmolding.org

Related Content

Lighter, Higher Performance Base Design for Premium rPET Bottles

Sidel’s StarLITE-R Premium base for thicker rPET bottles ensures bottle stability in high-speed production, while saving energy.

Read MoreAdding Remote Service Functions for PET Bottle Blowing

KHS has added features to its internet machine communications portal for PET stretch-blow molding.

Read MoreAll-Electric Shuttle and Stretch-Blow Machines

NPE2024: Meccanoplastica shows off a double-sided shuttle for containers up to 5 L and a reheat stretch-blow molder for up to 2.5 L PET containers with four cavities — both all-electric.

Read MoreCoca-Cola Europacific Transitions to Tethered Caps and Lighter PET Bottle

Sidel is converting all Coca-Cola PET bottling lines in Europe to meet new EU packaging regulations by July 2024.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More