Pay Attention to Heat Transfer

Injection Molding Know How

Money will be lost if cooling is not done right.

One of the most significant reasons molders have difficulty in reproducing a process, from run to run and machine to machine, is that the mold cooling is either not done properly, not done consistently, or is inadequately documented.

Cooling and coolant flow through cooling lines are not subjects for debate. This is a well-defined science that is taken seriously and used without question in every other industry that deals with heat transfer. It is a required course for many engineering degree programs, and if you find someone who ever took a course in fluid dynamics, watch their face as you bring up the memory. Nearly everyone who had the class hated it and could not wait to sell their textbooks. Why? It was a dull class where you get told what to do, were provided the equations, and then challenged to do all the calculations as a drill and proof of mastery of the science.

There was no debate of the validity of the equations or concepts, or whether they work or are practical. These same rules apply in a molding shop. People may not get hurt physically if cooling is not done right, but they certainly may be injured financially. Cooling is about 95% of your cycle time, so it deserves proper attention.

Let’s start with some of the basics on heat transfer:

1. Heat transfer requires a difference in temperature between the fluid and the metal cooling channel.

2. Maximum change in temperature, in vs. out, is 2° C (4° F).

3. You must have turbulent flow, as defined by the Reynolds Number; my target is 5000.

4. Because cooling rate can influence part dimensions and properties, you must duplicate the cooling rate from run to run, machine to machine, for the life of the mold.

PRACTICAL IMPLEMENTATION

The first step with any mold, new or old, is to find out the diameter of each water line, often easily determined by the NPT thread size. Once you know the cooling line diameter and the water temperature, calculate the minimum gallons per minute (GPM) or liters per minute (LPM) need to achieve a Reynolds number of 5000. There are free calculators on Google, though most are more complicated than necessary. I suggest setting up the Reynolds Number Equation using a spreadsheet with a viscosity table vs. temperature of coolant. Now sum up the required GPM for all the lines on each mold half. This will be the minimum GPM need for this mold. With a good spreadsheet this should take you fewer than 30 minutes. Remember, there are no ifs, ands, or buts about this minimum GPM required.

The real problem is ensuring that each cooling line gets the required GPM, and it has to be the same every time the mold is mounted in a press. It has to be regulated. This is not such an easy task, since coolant takes the path of least resistance on different size water lines, especially if you have baffles or bubblers.

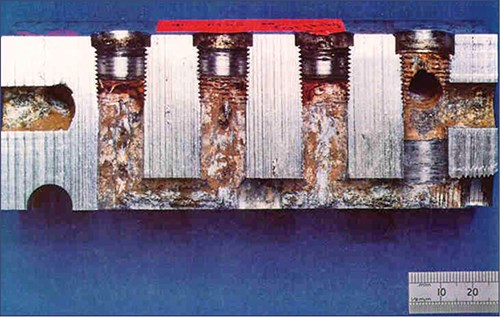

How close is your shop to having appropriate GPM, and is it regulated for each line? If you do indeed have everything in order, what happens if there is calcium, lime, rust, or some biological goo built up the inside of one or more of the lines? Let’s not pretend this does not happen, as some of you have seen lines completely blocked. Lines are sometime so badly fouled they have to be gun drilled out to clean them. What does this buildup on the inside of the cooling line do for heat transfer? The difference in in/out coolant temperature, or Delta T, drops astronomically, hence longer cycles and poor profits.

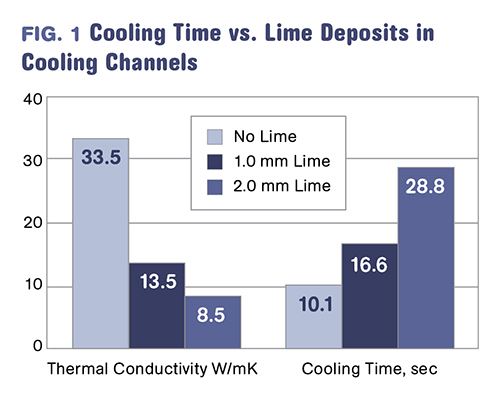

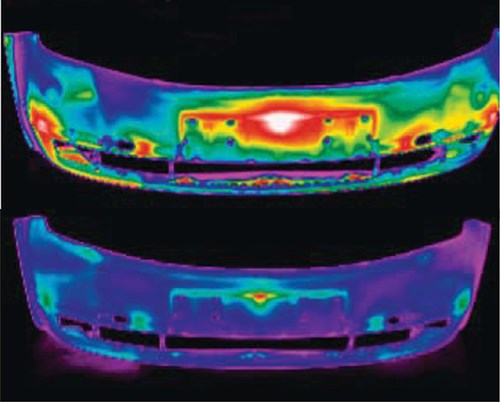

Figure 1 shows how a mere 2 mm of lime, calcium oxide, hydroxide, carbonates, etc., will nearly triple the cooling time required. Figure 2 shows thermal images of a mold before and after cleaning the water channels. In researching his book, Optimizing Injection Moulding by Thermal Images, Dr. Willi Stenko investigated more 700 molds and found 70% of them had extended cycle times due to fouled water lines, resulting in a revenue loss of about $60,000 per mold.

Dare I say that instead of spending money on the next Six Sigma Training, spend it on cleaning your molds. That would be a better return on investment. Our industry does not pay proper attention to cooling, water treatment, and keeping cooling channels clean. No ifs, ands or buts about that, either.

Related Content

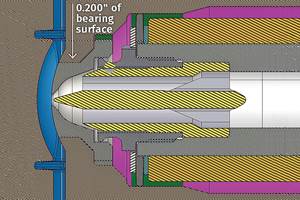

Hot Runners: Truths. Myths, Overlooked Areas: Part 2

Here’s a view from the trenches of a tooling manager who, over 30 years, has experienced the joys and pains of using virtually every type of hot runner on the market. Part 2.

Read MoreWhere and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MoreThree Key Decisions for an Optimal Ejection System

When determining the best ejection option for a tool, molders must consider the ejector’s surface area, location and style.

Read MoreWhy Shoulder Bolts Are Too Important to Ignore (Part 1)

These humble but essential fasteners used in injection molds are known by various names and used for a number of purposes.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More

.jpg;width=70;height=70;mode=crop)