Polyphosphonate: New Flame-Retardant Cousin of Polycarbonate

A new thermoplastic made by a polycondensation process similar to that used for polycarbonate offers high clarity, inherent flame resistance, and broad potential for copolymerization with PC and alloying with styrenics and polyesters.

A new thermoplastic made by a polycondensation process similar to that used for polycarbonate offers high clarity, inherent flame resistance, and broad potential for copolymerization with PC and alloying with styrenics and polyesters. FRX Polymers Inc., a two-year-old unit of Triton Systems Inc. in Chelmsford, Mass., developed technology to produce a phosphorus-based monomer and polymerize it into what will be the first commercial polyphosphonate (PPh) resins. FRX is qualifying PPh homopolymers and copolymers for melt blending as polymeric flame-retardant additives in engineering resins and for use as inherently flame-retardant transparent plastics in consumer electronics and other markets.

FRX's materials will compete with non-halogenated flame-retardant additives based on phosphorus. These include BPA/DPP (bisphenol A/diphenyl phosphate) and RDP (resorcinol diphenyl phosphate), both of which are liquids whose use is growing rapidly, especially in Europe for TV housings. Flame retardants like these can be used in clear thermoplastics, but they require the addition of PTFE to prevent dripping, which reduces clarity. There are also phosphorus-based flame-retardant masterbatches suitable for use in clear thermoplastics, such as Clariant Masterbatches' new CESA-Flam 5525 NH in a PET or PBT carrier.

(Incidentally, a low-molecular-weight oligomeric phosphonate flame retardant that is chemically similar to FRX was introduced recently for use in thermosets. Called Fyrol PMP, it comes from ICL-Supresta, div. of Israel Chemical Ltd. Industrial Products, and is used as a curing agent for epoxies.)

FIRST THERMOPLASTIC PPH

PPh polymers go back in patent literature to 1948, but were never commercialized because they had low strength, low Tg, and poor hydrolytic stability. In the 1980s, Bayer AG in Germany discovered a way to make PPh with better properties. But it was based on expensive ingredients that made it uneconomical. Eventually Bayer dropped the development.

Decades later, after Bayer's global head of plastics R&D, Dr. Dieter Freitag, retired from the company in 2000, he went to work as a consultant for Triton, an R&D company focused on performance materials. In 2003, Dr. Freitag began intensive research on PPh and solved a number of past technical problems, after which Triton set up FRX Polymers to commercialize the technology. FRX now claims 30 patents and patent applications on the monomer, diphenyl-methyl-phosphonate (DPP), and PPh polymers and downstream applications.

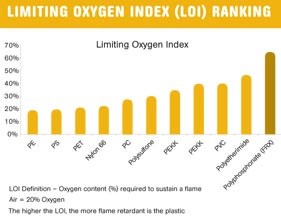

From DPP monomer, FRX has developed a PPh homopolymer resin, FRX 100, which is clear and inherently flame retardant, but brittle at room temperature, so it is marketed for use in alloys. By itself, FRX 100 has a limiting oxygen index (LOI) of 65%, reportedly the highest for any resin. (Rigid PVC has an LOI of 44%.)

FRX 100 has been tested at relatively low loadings in PET, PBT, PTT, copolyester TPEs, and ABS for its effect on flame retardancy, MFI, HDT, and mechanical properties. For instance, in glass-filled PBT, FRX 100 reportedly achieves a UL 94V-0 rating at 0.8 mm and a glow-wire ignition temperature of over 1500 F while retaining high modulus and showing improved notched Izod impact resistance, flow, and continuous tracking index (CTI).

FRX has also developed three PPh/PC block copolymers: FRX CO 20 with 20% PPh and 80% PC, FRX CO 25 with 25% PPh, and FRX CO 35 with 35% PPh. These can be used directly as clear, flame-retardant molding resins. FRX CO 35 achieves UL 94V-0 at 0.75 mm, which no other clear plastic can do, says FRX president and CEO Marc Lebel. PPh has higher flow than PC, so the copolymers are suitable for thin-wall applications. In general, more PC in the copolymer means lower LOI and MFR and higher Tg, HDT, and impact resistance.

FRX 100 homopolymer achieves a Tg of 217 to 225 F. Block copolymers have higher Tg because of the PC blocks. Tg is 286 F for FRX CO 20, vs. 295 F for 100% PC.

FRX is also testing blends of its block copolymers with ABS as competition for PC/ABS flame retarded with BPA/DPP in consumer electronics. "An alloy of FRX CO 35 with ABS delivers a UL 94V-0 rating at 1.5 mm, while also improving HDT by up to 40° C vs. commercially available FR PC/ABS," says Lebel. "In addition, FRX CO 35 will not migrate out of the alloy over time like phosphorus-based liquid FR additives."

"PPh should be cost-competitive with other engineering plastics," says FRX's Lebel. Because the manufacturing process to make PPh is similar to that for PC, FRX's business plan is to partner with PC manufacturers to produce PPh homopolymer and copolymers, which FRX will market globally as flame-reatardant additives. FRX already has five joint development agreements with resin companies.

Meantime, FRX is investing in a 1-million-lb/yr semi-works plant in Switzerland, through a joint venture with Uhde Inventa- Fischer GmbH of Germany. "The semi-works capacity will be used to commercialize the applications currently being worked on," says Lebel. FRX's 3300-lb/yr pilot plant in Chelmsford operates 16 hr a day, five days a week to supply test quantities and is sold out.

Properties of FRX in Copolymer & Alloys | |||

| Property | FRX CO 35 Copolyme | FRX CO 35 in Alloy with ABS | FRX 100 Homopol. in Alloy with 30% Glass-Filled PBT |

| Tensile Strength, MPa | 65 (Yield) | - | 100 (Break) |

| Elong. @ Yield, % | 5 | - | - |

| Elong. @ Break, % | 110 | - | 1.6 |

| Tensile Mod., GPa | 2.8 | 2.3 | 12.5 |

| Flex. Mod., GPa | 2.8 | - | - |

| Notched Izod Impact, J/m | 500 | - | - |

| Notched Charpy Impact, kJ/m2 | |||

| @ Room Temp. | - | 59 | 7 |

| @ -30 C | - | 20 | - |

| Falling Dart Energy @ Break, kJ/m2 | - | 39 | - |

| HDT, C | |||

| @ 0.455 MPa | 125 | - | - |

| @ 1.82 MPa | 115 | 120 | - |

| Vicat B, C | - | 137 | - |

| UL 94V-0, mm | 0.75 | 1.5 | 0.8 |

Related Content

How to Maintain Pelletizing Quality When Acid Attacks

Developments in the chemistry of polymers and additives have made corrosion a real problem in pelletizers. Here’s how to ward it off.

Read MoreHow to Configure Your Twin-Screw Barrel Layout

In twin-screw compounding, most engineers recognize the benefits of being able to configure screw elements. Here’s what you need to know about sequencing barrel sections.

Read MoreHow to Configure Your Twin-Screw Extruder: Part 3

The melting mechanism in a twin-screw extruder is quite different from that of a single screw. Design of the melting section affects how the material is melted, as well as melt temperature and quality.

Read MoreSmall Batches, Big Success

With no minimum order and an impeccable record of on-time delivery, Precision Color Compounds is becoming a force in the color masterbatch business.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More