Small Batches, Big Success

With no minimum order and an impeccable record of on-time delivery, Precision Color Compounds is becoming a force in the color masterbatch business.

It’s been said that he who hesitates is lost. Ten years ago, Erik Grotness didn’t hesitate, and now he isn’t lost. Grotness, at the time a partner of an automation company he co-founded, saw an opportunity to buy a fledgling color compounder and pounced. Today, Precision Color Compounds, Fort Wayne, Indiana, is an ISO-certified operation that produces color masterbatches to specification and focuses on speedy turnarounds and low-volume orders. Erik Grotness and his wife, Christiane, are equal partners in the business.

Grotness, the company’s president and CEO, recalls, “At the automation company, I started a division for plastics and plastics machinery in 2003, and so I knew the industry. The original founders of the company had backgrounds in polymers and compounding, but they were unaccustomed to how startups work. It can take a long time before you get that first paycheck, so nine months in, the original owners were looking for a way out. It so happened that one of the original owners approached one of my best friends and he made me aware of the opportunity. Basically, I saw a young company that really hadn't gotten started yet, and it interested me a lot because I really loved the people that had I met up to that point in the plastics industry.”

Initially, Grotness had four partners, but over time he bought them out. But the real challenge he faced at the onset was to how to make the company he just bought successful. “The funny part is that I thought I'd be approaching it from an engineering point of view, and once I realized all the chemistry that’s involved, I thought, ‘Oh boy.’”

Erik Grotness and his wife Christiane got into the color masterbatch business about 10 years ago with the purchase of Precision Color Compounds. Source: Precision Color Compounds

Fortunately for Grotness, the former owners brought with them seasoned technical people, including key personnel in the lab and in production. And many are still with him. “I remember one of our first meetings with the technical staff,” he says. “One of them was talking about an order and mentioned the LDR. I said, ‘Ok, what’s LDR?’ I learned it stood for let down ratio. And then I learned what that meant. And that’s, to this day, the great thing about people here and about people in plastics in general. They love what they're doing, and they love to share their knowledge.”

Grotness adds, “Being smaller, it wasn't like I had to walk 200 yards to the next office to try and get this kind of information. At the beginning especially, the team was all within a stone’s throw of each other, so we talked a lot and I got a lot of education from people that have been in the business 25-40 years.”

“I thought I'd be approaching it from an engineering point of view and, once I realized all the chemistry that’s involved, I thought, ‘Oh boy.’”

What Grotness also found to his liking was Precision Color’s value proposition serving that portion of the market that needed high-quality, small-batch orders delivered quickly. It’s a good thing because, at the time, the company had smallish (three 34-mm twins, one 89-mm single screw), refurbished machines that Grotness says, “were old as rock,” and weren’t positioned to run high volumes anyway.

“I quickly realized that was a good place to be, selling service, quality and speed. The automation company I was at worked that way, so I was comfortable with that mindset and knew it did well in good time and tough ones. And, in the color masterbatch business, I figured I can’t get a patent on this red or that orange, so let’s position the company as one that delivers a great product, made to the customer’s precise specifications and only the amount needed, and deliver it as promised.”

Not only is there a value in that proposition but Grotness soon realized there was a need. “Before I bought Precision Color, I spent a lot of time in the field talking to customers,” he recalls. “And the more I spent, the more I heard that service was a problem in the industry. The color masterbatch business was changing. Bigger companies were buying smaller ones, and they were buying bigger and bigger machines so they could focus on the high-volume markets. We joked that most of our competitors would do a small order 250- or 500-pound order as a favor to a customer. The only small line they had was maybe in the lab. Everything else was churning out maybe 2,000 pounds/hr.

“On a big line, on a 250-pound order you’ll probably make 250 pounds of scrap, just to get those big screws turning, before you make your first sellable pellet. So, right off the bat, the bigger companies are going to lose money on an order of that size. But that’s our sweet spot.” Precision Color offers 7-10 business day lead times; 48-hour color matching (upon request); and no order minimums.

Over the past two-and-a-half years, Precision Color has expanded the capacity of its masterbatch production by adding new lines.

Notes Grotness, “Think about it. With our location, we are in the epicenter of the plastics processing market. There is a lot of prototyping going on in the Midwest. A company in prototyping is not going to want to buy 500 pounds of material because it will be sitting on the shelf for a very long time. The good thing about concentrates is that they are easy to transport. There have been times where we’ve had a 100-pound order for a customer as much as a couple hundred miles away, but their delivery needs suddenly changed and they’ve called us and let us know they really need all or at least a partial of the order ASAP. Most times we’ve been able to squeeze in what they needed in production because of our frequent color rotation , put it in a car or truck and say ‘ok, you drive toward me, I’ll drive toward you, and we’ll meet halfway.”

Notes Tom Gavinski, Precision Color’s national sales and marketing manager, “So many of our customers tell me ‘We really enjoy the fact that, when we call, somebody picks up the phone.’ Or ‘I always hear back from you guys within an hour.’”

At Precision Color, the company changes orders an average of 3-4 times a day. On some occasions, though, that could amp up to 2-3 times per line, depending on the order quantity. In a perfect world in the color masterbatch business, Grotness notes, product runs would be scheduled light to dark to help streamline the changeover process. “If our customers gave us their orders three months ahead of time, we could stagger them that way, but that’s not reality.”

So, Precision Color takes another approach, tackling product changeovers with a pit crew mentality. Grotness explains: “In earlier years, I was fortunate to have a friend who was a sponsor for (legendary driver) A.J. Foyt, so I spent a lot of time with IndyCar racing. On our plant floor, we have a large photo of A.J. Foyt’s pit crew in action to remind us of our pit crew mindset. But just like in IndyCar racing, in color masterbatch production, not only do you have to be fast in color changeovers but you also have to be right. We know that if you leave one little speck of red hanging in the machine and you want to start running a white, well you just made pink, and now you're just throwing the whole thing away. And we focus a lot on training so that all of our operators can work interchangeably on all the machines we have.”

As part of this training, which involves in-house instruction from Leistritz Extrusion, the company’s primary supplier of twin-screw compounding machines, one of Precision Color’s operators is a “floater” who is cross-trained so that he/she can help execute a change on any machine the company has. Grotness explains, “A color change involves not only the extruder but everything downstream — the feeder, pelletizer (Precision Color runs both strand and underwater) and the classifier. Having a floater be familiar with all this equipment on all lines has allowed us to cut color-change times in half in some cases.

“In color masterbatch production, not only to you have to be fast but you also have to be right.”

Changes typically involving purging and complete screw pulls. Says Grotness, “We have evolved to where we're testing purges and verifying which purges work best on each machine. And it’s not always the same purge. On some lines, it might be a mechanical purge, and other a chemical purge. And we’re evaluating hybrids now and we’re getting close to choosing one. But then in six months, we'll reevaluate.”

The pit crew mentality also enables Precision Color to handle those last-minute requests that are typical in the masterbatch business. Says Grotness, “Our business model is not, for example, looking for orders that will constitute a three-, two- or even one-day run. Our business is being nimble and shifting quickly from one order to the next. Our manufacturing staff understands the mentality and they'll always figure out ways to sandwich in that 50-, 100- or 200-pound order that the customer needs right away and make suggestions during our daily production meeting. We can do a lot of things like that because we're in and out of so many different colors during the day.”

Adding Capacity

Precision Color has invested more than $2 million over the last two and a half years to expand, to the point where when asked about his manufacturing footprint, Grotness noted that it’s changing so quickly that even he has issues putting a number on it. He did divulge that the company just added 15,000 square feet of manufacturing capacity and is now in talks to add more. Precision Color’s capacity these days is around 9 to 11 million pounds, but that would be in ‘ideal’ situations, and those don’t exist. “In our position in the market, realistically stating an accurate capacity is not possible. We run so many orders with multiple different compounded additives, speckles, pearls, fluorescents, etc., all with different LDRs, so depending on the order you may or may not be able to run at the machines ‘stated capacity,’ Grotness says. “In order to always have enough flexibility, however, our goal is to never use more than 80% of our capacity on a regular base. Meaning, if our lines continually are full, we add more capacity.”

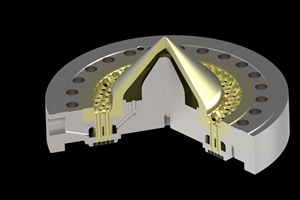

Precision Color still runs one of the older machines Grotness inherited when he bought the company, but it has added two new 27-mm twin-screw lines from Leistritz Extrusion, as well has an 18-mm lab line. This year, it is considering adding either another 89-mm and/or perhaps a smaller machine. It also has a single-screw extruder that is uses for PETG color masterbatch. Says Grotness, “We’re now more successful, so that we're planning to continue to buy new, not possibly buying somebody else's problems and then trying to keep it running. We’ve settled on Leistritz as our primary supplier. We’re very happy with their technology and especially their support and service.”

Precision Color will integrate the extruders in-house with all upstream material handling and downstream, most likely underwater pelletizing and classifying equipment. “We have also added an ECON NWA400, a hybrid pelletizer which can shift from underwater to air pelletizing, in order to process bioresins which are hydroscopic in nature in order to make sure we have the capability to handle most anything our customers might need,” Grotness adds.

In terms of adding the bigger machines, Grotness notes that two is better than one. He elaborates, “For those orders in the 5,000-10,000 range, while we don’t get that many of them, we get enough so that we don’t want to risk a larger order monopolizing a smaller machine. So, we’ll put them on the bigger machines and keep those machines sacred for the larger orders.” The color concentrate compounder runs one shift, though Grotness anticipates that could change over time.

A fully instrumented lab ensure color masterbatch is compounded to specifications.

In the view of Gavinski, a seasoned sales professional who has worked in the sheet and profile extrusion business in his career, these larger orders are usually made possible by successfully executing a smaller one. “Typically, when we go in and talk to a new customer, they will tell us that they work with three or four different color concentrate houses, and we’ll say that's great because our spot is the small applications. But a lot of these small applications tend to be unusual. We might get asked if we can do 25 pounds of a yellow in acetal. The answer is yes. But over time, when you perform like you said you would, these kinds of orders graduate to more and more business. So that’s the that's the journey we’re on now. If we can get the 25-pound order, it's amazing how quickly 25 becomes 50 becomes 100 pounds, and it kind of goes up like that and suddenly we’re running a new material that five years ago we didn't even know how to spell.”

“We might get asked if we can do 25 pounds of a yellow in acetal. The answer is yes.”

While Precision Color has the expertise to compound using any type of polymer system, most of its business to date has been polyolefin-based. In the last year, though, it has added capabilities to handle biopolymers and can run a wide range of engineering resins. Its customers range from custom molders to profile extruders to prototype operations.

Gavinski notes that the company’s growth can be attributed evenly from new and existing customers. “There have been some decisions made by some of our competitors that have caused the customers to just shift more business to us because we are not difficult to work with. There are customers we got where the bigger color houses didn’t want to fill their 50-pound order. They’d give them the price for their 250-pound minimum order. When they come to us, not only do they get the 50 pounds they need but they also get it the next week. So, with a molder, for instance, they are not only getting color quicker but are able to produce parts quicker.

“We're in the high 90% in terms on-time delivery, and it’s really remarkable for plastics because 8- to 10-week lead times just don't work for a lot of people. We rarely miss a delivery date.”

Adds Grotness, “Color is so important, yet it’s generally the last thing people think about. In molding, the customers think about the machine, the tool and a lot of other things. No one in plastics gets to work and turns on the computer first thing and says, ‘Let me call Precision Color and see what they are up to today.’ But we are going to be there when you need us. It is 100% the people, our team, and we get everybody involved. Sometimes one of our lab people will make a delivery because we want our customers to feel comfortable with multiple people in the company. Our most important asset walks out the door every night. ”

Related Content

Sirmax Adapts Integrated Recycling Approach to US Supply Conditions

Integrating compounding and recycling to leverage untapped postindustrial recycling feedstocks.

Read MoreHow to Maintain Pelletizing Quality When Acid Attacks

Developments in the chemistry of polymers and additives have made corrosion a real problem in pelletizers. Here’s how to ward it off.

Read MoreImproving Twin-Screw Compounding of Reinforced Polyolefins

Compounders face a number of processing challenges when incorporating a high loading of low-bulk-density mineral filler into polyolefins. Here are some possible solutions.

Read MoreHow to Configure Your Twin-Screw Extruder for Mixing: Part 5

Understand the differences between distributive and dispersive mixing, and how you can promote one or the other in your screw design.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More