Leistritz Extrusion

Extrusion

175 Meister Ave.

Somerville, NJ 08876 US

908-685-2333

sales@leistritz-extrusion.com

extruders.leistritz.com

About Leistritz Extrusion

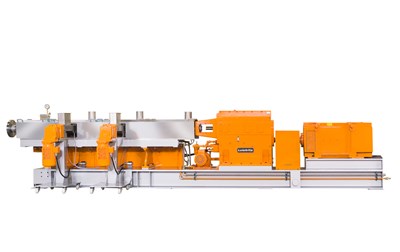

Leistritz Extrusion manufactures co-rotating, intermeshing twin screw extruders (TSEs) with screw diameters from 12 to 260 mm, and supplies systems for compounding, devolatilization, reactive processing, foaming and direct extrusion. A fully equipped process lab is available in NJ, USA.

IS THIS YOUR COMPANY?

As Seen On Plastics Technology

Leistritz Extrusion Supplies the Following Products

- Intensive Fluxing (melting) Mixers

- Multiple-screw Extruders

- Pelletizers

Editorial, News, and Products

-

Building a Future With Sustainable Compounds

With roots in recycling, Star Plastics produces engineering thermoplastic compounds to meet performance and environmental goals.

-

Small Batches, Big Success

With no minimum order and an impeccable record of on-time delivery, Precision Color Compounds is becoming a force in the color masterbatch business.

-

Processing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

-

Equipment for Compounding, Reactive Extrusion, Devolatilization, Foaming and Direct Extrusion

NPE2024: Leistritz to focus on advances made via twin-screw extrusion.

-

Scaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

-

Foam Processor Innovates on Path to Sustainability

Nomaco does foam and only foam, innovating solutions for consumers that not only solve problems but are better for the environment.

-

How to Configure Your Twin-Screw Extruder: Part 3

The melting mechanism in a twin-screw extruder is quite different from that of a single screw. Design of the melting section affects how the material is melted, as well as melt temperature and quality.

-

More Than a Compounder: They Have the Science to Create New Custom Materials

Insight Polymers & Compounders leverages its expertise in polymer chemistry to develop next-generation materials.

-

10 Ways to Improve Twin-Screw Compounding Performance

There are many techniques known to operators and plant engineers for increasing the performance of a twin-screw compounding extruder.

-

Star Plastics Adds Leistritz Compounding Line

Twin-screw was installed at its West Virginia plant in December as part of $5 million expansion.

-

Leistritz Adds Post to Sales Team

Extrusion veteran joins machine builder as product manager for life science and specialty film applications

-

Troubleshooting the ‘Mixing Experience’ in Corotating, Intermeshing Twin-Screw Extruders

The metering equipment, twin-screw extruder and downstream systems all must work in concert to control the properties of the final part and manage the process of mixing.

-

A Coronavirus Comeback Restarts Growth at Medical Compounder

A slowdown in catheter production stopped growth in its tracks last year at Foster. But business has turned around quickly this year, and the medical compounder was prepared for the rebound.

-

The Experts Speak: Seven Cost-Saving Purging Tips for Compounding Twins

Purging gurus from the material, machinery and compounding sides of the industry offer their insights on best practices and tips that can keep your compounding twin-screw extruder up and running.

-

The Buck Stops … at This One-Stop Compounder

CRC Polymer Systems brings expertise in material selection, product formulation and processing, and a thorough understanding of part design and tooling under one roof with a series of customized materials and capabilities aimed at OEMs and molders.

-

How and Where Twin-Screw Extruders Fit in Recycling

When utilized in a thoughtful way, the corotating intermeshing twin-screw extruder can transform recycled materials into value-added products and parts. Here’s what you need to know, and some real-world examples of the technology deployed for both post-industrial and post-consumer recycling.

-

Reactive Extrusion: Industry Icons Impart Their Insights

Three distinguished experts in the area of reactive extrusion shed some light on this process.

-

Why It's Crucial to Manage Melt-Temperature in a Twin-Screw Compounding Extruder

Managing and controlling melt temperature and degradation in a corotating compounding twin is critical to achieve process optimization. For compounders, it also greatly influences the ability of their molding and extrusion customers to make high-quality parts. Here are the results of research that illustrate this.

-

Compounding: Revamped Line of Compounding Twins

Third-generation iMAXX twins are easier to clean and maintain, and are more energy efficient to boot.

-

Who’s Doing Research to Advance the Plastics Industry?

Machinery suppliers are taking the lead in plastics R&D. Engel offers one example.

-

Leistritz Adds 3D Filament Line to Lab

System helps customers develop and produce 3D filaments from a co-rotating or counter-rotating twin screw extruder.

-

‘Follow the Plan’ When Installing and Commissioning Compounding Lines

A fully operational and documented system doesn’t happen by chance. An efficient, well-designed installation plan, prepared well in advance, will put you on the path to maintaining a timeline and budget.

-

Extrusion/Compounding at NPE2018: More…More…More!

More speed, flexibility and robustness. Across a gamut of extrusion applications, machine builders are introducing new machinery, components, and systems to dramatically raise the bar on productivity.

-

NPE2018 New Technology Focus: Compounding

Check out what’s new in compounding at this year’s big plastics industry trade show.

-

Gamut of New Technologies for Compounding

Leistritz Extrusion’s wide-ranging display of twin-screw extruder related technologies at NPE2018 includes a system for manufacturing 3D filaments.

-

Coextrusion Line Demonstrates Technology for API Catheters

At trade show, suppliers team to show how to run a medical tube that includes medicine.

-

What You Can Learn From Pharma Compounders

Twin-screw extrusion has been a standard in plastics compounding for decades but has only recently been embraced by the pharmaceutical industry. Here’s what plastics compounders might learn from the ‘newbies’ to help make a better, more consistent product.

-

K 2016 Extrusion: Speed, Versatility Rule the Day at K

Shorter product runs mean frequent product changeovers for processors, and suppliers responded to these trends across all extrusion technologies.

-

Service & Response Drive Growth of Custom Compounder

Lanier Color has experienced an eightfold increase in business since 2000. Its focus on technical support and customer service help explain why.

-

K 2016 Preview: Extrusion and Compounding

Regardless of what you might be extruding, the themes of speed and flexibility will loom large in extrusion at the giant show.

-

Get Better at Swapping Out Your Twin-Screw Elements

Here’s what you need to know to safely and efficiently remove, clean, restage, and reinstall your twin-screw extruder screw set.

-

Chinese TPE Compounder Reshores to Chicago Area

New TPE compounder in the Midwest launched by a Chinese-born, U.S. citizen who already had a successful compounding operation in his homeland.

-

EXTRUSION AND COMPOUNDING NPE: Flexibility, Speed and Quality

Extrusion processors need more—of everything—to compete. And suppliers responded in force in Orlando.

-

EXTRUSION AND COMPOUNDING AT NPE: The Word Is ‘More’

As in speed, power, quality, flexibility, layers, and efficiency. Those are the trends across all extrusion processes.

-

Color Compounder Enters Market with a Bang

To get noticed in the color masterbatch business—particularly in white—you’ve got to start big. That, and new technology, form the foundation for startup Neko Colors

-

Teel Plastics: Where Science, Tech, Quality and Innovation Meet

This family-owned custom profile and tubing business controls its own destiny by controlling, well, everything.

-

Compounding PLA on Twin-Screws: What Testing Reveals

Twin-screw extrusion is the preferred method for compounding PLA and other biopolymers. But processing PLA is complicated because it’s sensitive to heat and shear. It’s also prone to hydrolytic degradation if moisture is present in molten PLA. Here’s what one machine builder’s trials revealed.

-

Recycling News at K 2013

New developments combine recycling and compounding in one step. Plenty of news at K in size reduction and de-labeling.

-

Extrusion/Compounding at K 2013: Having It All

Extrusion processors no longer need to chose among speed, quality, and flexibility, based on exhibits at K 2013.

-

Bioresin Company Takes ‘Do It All’ Approach

Company adopts 'cradle to cradle' approach.

-

Extrusion & Compounding at NPE: More Output, More Flexibility, Less Energy

There won't be many blown-film lines running, but there is still much in the way of innovation going on in extrusion and compounding.

-

Look Before You Leap: When Direct Extrusion Makes Sense

The process offers great opportunities to extrude a better product at less cost, but it’s not for everyone. The formulation, product mix, and anticipated volumes must be carefully assessed to determine whether DE is the preferred manufacturing methodology.

-

Compounding: New Torque Record Set At K '10

New twin from Coperion also pumps up output by 30%

-

EXTRUSION & COMPOUNDING: Five-Layer Film Structures Set to Supplant Three Layers?

In blown film, equipment and material suppliers have come together to push five-layer technology into non-barrier applications previously held by three-layer films.

-

Extrusion at NPE 2003

NPE is typically a competitive display of the biggest, most dramatic equipment machine builders can muster.

-

Long-Fiber Thermoplastics Extend Their Reach

Smaller parts, a wider range of resins and reinforcements,and retrofittable molding equipment were among the news indirect-compounded long-fiber thermoplastics presented at a recent Plastics Technology conference. Extrusion and thermoforming are also new extensions of this process.

-

North America's Best-Kept Secret in Compounding

They’re hardly a startup, having opened their doors 27 years ago this month.

-

NPE News in Compounding

Compounding news at the show includes several new ways to feed low-bulk-density materials faster for higher outputs with corotating twin screws.

-

What's New at the Show in COMPOUNDING

Compounding machinery news at the K Show next month focuses on more torque, more output, and sometimes both, for kneaders, mixers, and twin-screw extruders.

-

What to See at NPE 2006: Compounding and Mixing

Throughput capacities are going up for compounding equipment of all types.

-

K 2004 Wrap-Up on Compounding: Quick Changes and Hybrids Add Versatility

New compounding technologies displayed at K 2004 included some unusual ways to broaden the range of products a twin-screw compounder can make.

-

K 2004 News Preview: Compounding

Compounding news at the K Show includes the use of alternative motors to save space and raise output on twin-screw machines.

-

Now Molders Make Their Own GMT Sheet

The latest sign of an upsurge of interest in direct long-fiber compounding by molders of reinforced thermoplastics is a technology that allows molders to produce their own glass-mat thermoplastic (GMT) composite sheet.

-

NPE Highlights Compounding's Growth Niches

Show exhibitors say long-fiber wood composites, direct extrusion/compounding, and reactive compounding are where the action is.

-

Torque & Speed How Much Is Enough?

You may be thinking of buying one of the new ‘high-torque/high-speed’ twin-screw compounders in order to raise your output without going to a larger machine. But how much torque or speed do you really need? Underusing a high-powered extruder wastes investment dollars. So look carefully at what is required for the materials you run.

-

Twin-Screws & Kneaders Pack More Muscle

This K show demonstrated the continuing evolution toward higher torque, screw speed, and throughput rates in twin-screw compounders. There were also new developments for reducing wear when processing filled compounds and new processes available for license to compound wood and paper fibers with plastics. There were even some improvements in backflushing screen changers.

-

Compounding (K 2001 Preview)

Compounding equipment at K presents not so much new technology as new modifications or combinations of equipment to improve output and conserve space.