Equipment for Compounding, Reactive Extrusion, Devolatilization, Foaming and Direct Extrusion

NPE2024: Leistritz to focus on advances made via twin-screw extrusion.

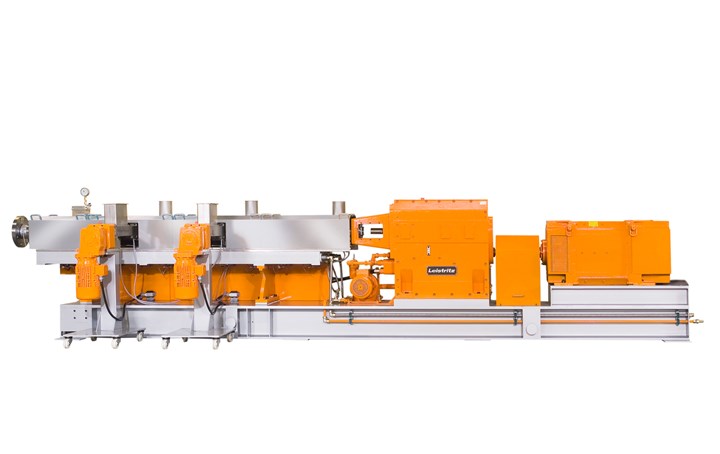

At NPE2024, the theme of the Leistritz Extrusion exhibit is The Race to Success, which is representative of the continued advancements made possible via twin-screw extrusion to make better products at a lower cost. The following equipment is on display:

ZSE-60 MAXX co-rotating twin-screw extruder: The 60-mm MAXX features a modular design for barrels and screws that are rated for 425°C operation. Auxiliary equipment integrated with the MAXX includes an LSB-side stuffer for downstream introduction of fillers into the process section and an LSA swing gate strand die with provision for filtration.

ZSE-40 MAXX co-rotating twin-screw extruder: Well suited for color concentrates and small lot production, the ZSE-40 MAXX also features a modular design and an LSA swing-gate strand die. An AC water-cooled motor is integrated into the machine design, which operates more quietly than air-cooled motors, and eliminates unwanted air flows in the plant.

ZSE-27 MAXX co-rotating twin-screw extruder: The ZSE-27 MAXX is suited for research and full-scale production and features a quick-change flangeless barrels design for accelerated barrel reconfiguration, as well as a gearbox is attached to a dovetail mounting plate that enables the gearbox to be quickly repositioned to facilitate different L/D ratios testing. All electricals are integrated into a roll-around stainless-steel base, and an Allen-Bradley PLC/HMI controls architecture will be displayed.

ZSE-18 twin-screw extruder: Well suited for R& D, the ZSE-18 offers a fully segmented design and can operate from ½ to 10+ kg/hr. A base-mounted LSB side stuffer enables downstream introduction of fillers, fibers and shear-sensitive materials into a process melt stream. A highly customized front end consisting of a gear pump positive displacement device and candle filtration assembly will be mated to a film die. All electricals are integrated into a roll-around stainless-steel base, and a Siemens PLC/HMI controls architecture is a brand new feature.

ZSE-12 twin-screw extruder: Exhibited for the first time at NPE, this machine is suited for continuous operation and is designed for low rate and small batch processing. Modular stainless-steel barrels and screws are assembled on splined shafts. The process section can be configured for liquid injection and multistage devolatilization. The feed section is equipped with a patented microplunger feeder, which facilitates processing as little as 50-100g batches.

Related Content

-

The Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.

-

Reduce Downtime and Scrap in the Blown Film Industry

The blown film sector now benefits from a tailored solution developed by Chem-Trend to preserve integrity of the bubble.

-

Roll Cooling: Understand the Three Heat-Transfer Processes

Designing cooling rolls is complex, tedious and requires a lot of inputs. Getting it wrong may have a dramatic impact on productivity.