Color Compounder Enters Market with a Bang

To get noticed in the color masterbatch business—particularly in white—you’ve got to start big. That, and new technology, form the foundation for startup Neko Colors

Say this about Neko Colors Inc.: When they decided to open their doors in late 2013 they didn’t just dip their toes in the water. They did a cannonball.

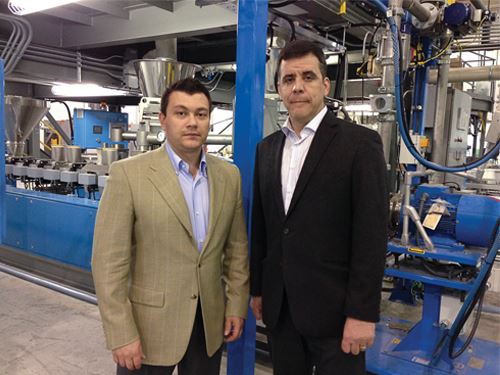

Based in a 40,000 ft² facility in LaSalle, Que., this startup color compounder knew going in that if it was going to be a success in supplying white, color, and additive masterbatches—primarily for polyolefins—it was either all-in or not at all. “Our capacity is 25 million lb/yr, and that’s just in white,” states Dmitry Korenblit, part of Neko’s family ownership team.

“We’re unique in the sense that most color houses usually start up on a much smaller scale,” adds Ron Stark, Neko’s v.p. of operations. “But as the new kid, we made the decision right away that if we were to compete against long-established players in the market we could not do so in a small way. Especially in the white masterbatch business, you have to be big to get noticed.”

Korenblit and Stark are among the 10 people Neko currently employs. Both have entrepreneurial backgrounds in manufacturing, chemicals, and distribution. Stark began his career with a masterbatch company that was subsequently bought by Spartech (now part of PolyOne).

Neko made another strategic decision when it opened shop: It bought brand-new equipment. “It would have been easier and less expensive for us to buy used equipment, and there was plenty of it on the market,” recalls Korenblit. “But again, in an effort to differentiate and make it clear how serious we are, we went to the K2013 show in Dusseldorf last October looking for state-of-the-art German-built equipment.”

The new firm opted for three high-speed, high-torque Maxx extruders from Leistritz (U.S. office in Somerville, N.J.; leistritz-extrusion.com). Neko would not divulge the sizes of these machines. It did note that the first two were commissioned within three months after a purchase order was issued. The third extruder—the largest of the trio—was being brought on line as this article went to press. All are equipped with multiple feeders and are fully automated “from silo to packaging,” as Korenblit puts it. The facility has room for three additional lines, Stark adds, noting that Neko expects to double its workforce before long.

Locating its plant in Quebec made sense for Neko for a number of reasons. Explains Korenblit, “First, there is a big customer base of molders and film extruders in the province, and no one is manufacturing product at the scale we are planning. Second, the transportation infrastructure in Montreal is excellent, with easy access to shipping by rail, sea, and air.” Neko’s plan is to sell throughout North America and around the world.

Adds Stark, “When we were formulating our plan, we looked at getting in the business by buying a competitor. But starting from a fresh piece of paper and getting the best technology into the building from day one made better sense. We made an outstanding product from the first pound, and we have the solid financial backing, technical expertise, and great mix of people to grow the business moving forward.

Related Content

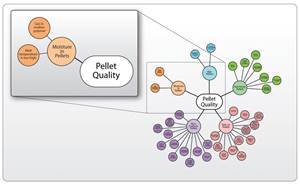

The Path to Pellet Perfection

In underwater pelletizing, numerous variables in the equipment, process and material affect pellet shape, consistency and quality factors such as fines. Defining the “perfect” pellet depends on the conditions of end use, and achieving that ideal requires understanding of the causes of imperfections.

Read MoreSmall Batches, Big Success

With no minimum order and an impeccable record of on-time delivery, Precision Color Compounds is becoming a force in the color masterbatch business.

Read MoreProcessing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MoreHow to Configure Your Twin-Screw Extruder: Part 3

The melting mechanism in a twin-screw extruder is quite different from that of a single screw. Design of the melting section affects how the material is melted, as well as melt temperature and quality.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More