Now Molders Make Their Own GMT Sheet

The latest sign of an upsurge of interest in direct long-fiber compounding by molders of reinforced thermoplastics is a technology that allows molders to produce their own glass-mat thermoplastic (GMT) composite sheet.

The latest sign of an upsurge of interest in direct long-fiber compounding by molders of reinforced thermoplastics is a technology that allows molders to produce their own glass-mat thermoplastic (GMT) composite sheet. This development is driven by the desire to reduce raw-material costs by not having to buy pre-made sheet. Do-it-yourself compounding also gives GMT molders a means of reusing their scrap. Further savings are offered by immediate transfer of fresh-made sheet into the press while still molten, eliminating an energy-consuming reheat oven.

This “LFT-D-ILC” (long-fiber thermoplastic direct in-line compounding) process was highlighted at the recent K 2001 show by Dieffenbacher GmbH & Co. of Eppingen, Germany. (Dieffenbacher North America Inc. is located in Windsor, Ont.) Dieffenbacher, primarily a maker of large hydraulic presses, developed a complete integrated compounding and molding system with help from the Fraunhofer Institute for Chemical Technology in Pfinzstal, Germany. Nine of these systems are running in Europe, primarily for automotive manufacturing, and the first in North America was installed at the end of last year by Meridian Automotive Systems’ Commercial Truck & Industrial Products Div., Salisbury, N.C.

How it works

The essence of this process is the separation of mixing and melting the thermoplastic from compounding of the long-glass fibers. The process starts with gravimetric metering of resin —polypropylene in all cases so far—plus additives (color masterbatch and glass-coupling agent) into a corotating twin-screw extruder from Leistritz AG in Germany (Leistritz Extruder Corp. is in Somerville, N.J.). A typical system uses a model ZSE/60/GL with 60-mm diam. screws, 32:1 L/D, and throughput capacity of 1100 to 1320 lb/hr. This machine can also reprocess small bits (8 to 12 mm) of GMT scrap.

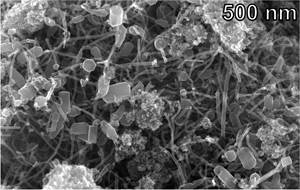

The ZSE extrudes a film of melt through a slit die into a short (8D) twin-screw device, model ZSG, designed by Dieffenbacher and built by Leistritz. The ZSG is the heart of the system, where the resin and glass are brought together. Continuous glass rovings fed from reels are spread over heated rods, and preheated at 428 F. Reciprocating rollers open up the fiber bundles while they are preheated. The short twin screws pull in the rovings and gently wet them with PP while avoiding excessive fiber breakage. As shown in the accompanying diagram, a single-screw extruder can feed larger pieces of shredded scrap into the ZSG while preserving the long fibers. (One European application, a Volkswagen front end, can use up to 30% scrap.)

The ZSG feeds GMT through a sheet die onto a conveyor belt. An automatic blade mounted on the die cuts the GMT into blanks of uniform weight. A jointed-arm robot equipped with needle grippers grabs the sheet blanks and places them while still hot into the mold of a compression press. The entire system is controlled from a central PC terminal.

Dieffenbacher tested auto front-end modules molded from standard 40%-glass PP GMT and identical material that was compounded in-line. Mechanical properties of the two parts were virtually indistinguishable, but Dieffenbacher says costs can be reduced by up to 40%.

Now in America

Meridian sources expect the LFT-D-ILC process to make its U.S. debut in the second or third quarter. Prototypes have been run in a still-secret program involving a commercial vehicle. Trials involve both structural and textured appearance parts.

The plant will ultimately have three ILC systems, one capable of about 1320 lb/hr and two capable of 1100 lb/hr. One of the smaller systems has already been installed. The systems each will occupy around 1500 sq ft, not counting the mezzanine for the gravimetric feeding and blending. Each system will cost in the neighborhood of $1 million, including the robot but not the press. At press time, the plant had not yet installed either the robotics or regrind feeding system.

Expanding potential

Meridian’s Salisbury plant currently molds mainly thermoset SMC. Engineers there see potential for GMT to replace not only some SMC parts but also metals and engineering plastics.

Meanwhile, Dieffenbacher is expanding its development efforts into construction applications such as cement-mixing boxes that are hoisted by construction cranes. The company is also working on higher output systems for up to 2200 lb/hr and on formulations utilizing long natural fibers such as flax, hemp, sisal, or wood. Other possibilities include utilization of carbon fibers, mineral fillers, and other polymers like nylon or PET.

Related Content

Research Suggests Path From Waste Plastics to High Value Composites

Flash joule heating could enable upcycling of waste plastic to carbon nanomaterials.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More