How and Where Twin-Screw Extruders Fit in Recycling

When utilized in a thoughtful way, the corotating intermeshing twin-screw extruder can transform recycled materials into value-added products and parts. Here’s what you need to know, and some real-world examples of the technology deployed for both post-industrial and post-consumer recycling.

Plastics plays a role in all facets of modern life, from health and well-being, nutrition, shelter and transportation, to safety and security, communication, sports, and leisure activities. The plastics compound that is used to manufacture these parts almost always has been processed on a corotating twin screw extruder (TSE). These devices are used to mix materials to impart desired properties to products such as packaging films, carpet fibers, car interiors and windshields, structural decking, conductive parts, and synthetic wine corks.

How do we recycle these products after use? What’s the difference between post-industrial (PIR) and post-consumer (PCR) recycling? A scant few corotating twin-screw extruders are used for recycling nowadays. Why? And where are there opportunities for the expansion of TSE technologies?

Twin-screw compounding technologies offers some unique opportunities for both PIR and PCR. But besides being aware of the benefits of TSE technologies for recycling, it’s also important to be wary of some of their inherent limitations to determine appropriate use of this industrially proven, battle-hardened technology.

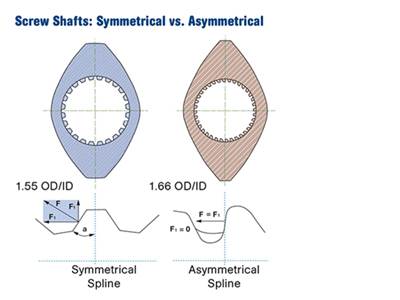

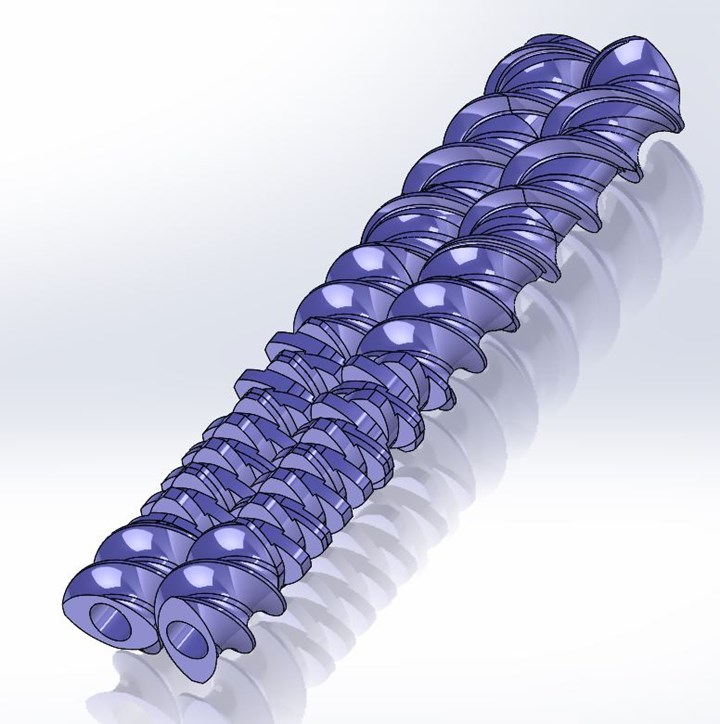

The corotating intermeshing twin-screw extruder is the most prevalent compounding system in the world today to mix polymers with fillers, fibers, and additives. The TSE is a high-speed mixer with tight geometric tolerances for screws and barrels. High-speed rotating screws (100 to 1000+ rpm) and mixing elements impart shear and energy to the materials being processed. The intense inter-screw mixing and the short mass-transfer distances (flight depth) makes the TSE a highly efficient, repeatable, and versatile continuous compounding device. For instance, a Leistritz ZSE-140 Maxx with 140-mm screw diam. has a flight depth of approximately 28 mm. Mixing elements can be specified as dispersive, distributive, or a balance of each.

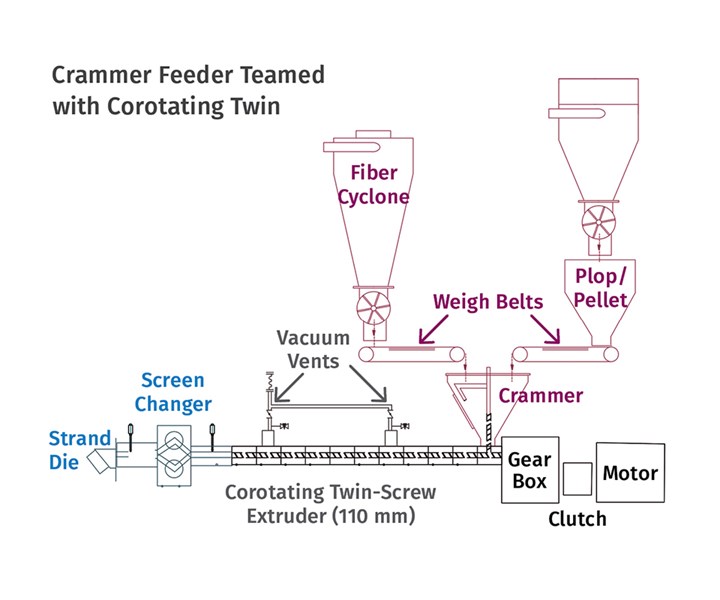

Crammer feeders are teamed with corotating twins in applications that include post-industrial nylon reclaim from bales.

Crammer feeders are teamed with corotating twins in applications that include post-industrial nylon reclaim from bales.The feed system sets the rate and formulation percentages to the TSE for feedstocks that include pellets, powders, regrind, liquids, fibers or even “fluff.” The TSE is “starve-fed” and screw rpm are independent from the feed rate. Flighted screw elements (partially filled) are placed underneath feed and downstream vent/feed locations, facilitating strategic sequential feeding and preventing vent flooding. Crammer feeders are used for inert fillers and low-bulk-density materials. Entrapped air, moisture and volatiles are also removed via venting. The TSE screws design, rpm, throughput rate, temperatures are determined in concert to optimize the specific process.

The starve-fed TSE process facilitates mixing and devolatilization, but not for operating at high pressures. TSEs generally run at less than 1500 psi. Another reality is that contaminants and foreign objects (i.e., a screw bolt) in the feed stream can damage the screws, lock the machine up and maybe result in a very expensive repair.

TSE technologies are being applied to non-traditional recycling operations to manufacture a variety of new products.

By comparison, single-screw extruders (SSE) are low-speed, high-pressure devices that are designed to build (and stabilize) elevated pressures (3000+ psi) but are not as suitable for intensive mixing. High-pressure pumping capability makes the SSE preferred for many recycling operations. It is also more forgiving of contaminants in the process stream. For these reasons, SSEs may be the preferred extruder type for many reclaim systems, particularly for PCR. But not always.

TSE technologies are being applied to non-traditional recycling operations to manufacture a variety of new products. In the context of the above discussion, the following statements apply to corotating, intermeshing TSEs for recycling:

• Recycling is an area where TSEs have not been widely used, particularly for PCR applications, due to difficulties/limitations associated with processing contaminated feedstocks.

• TSEs are more often used for PIR applications—for example, feeding edge trim from film and sheet processes back into the same system.

• Post-industrial feedstocks are more typically compounded with additives, fillers, and fibers for value-added compounding.

• The starve-fed TSE is a better mixer than a pump, and the single-screw extruder (SSE) is a better pump and less of a mixer.

• TSEs, as compared to SSEs, are low-pressure machines, rated for operation at less than 3500 psi and seldom operated above 1500 psi.

• TSEs tend to run at much higher screw speeds (400, 600 or 1000+ rpm) than SSEs.

• Almost every TSE integrates venting/ devolatilization into the process, with multi-stage venting being common.

• Most TSEs make pellets where dimensional tolerances are a secondary concern to achieving a well-mixed pellet.

• Filtration is too complicated an issue to be addressed in this article, except to state that it often drives the design of the system, and it requires elevated pressures. Some of the factors include filtration level (micron or mesh rating), filtration area, continuous vs. discontinuous operations, associated pressures, contamination level and type, formulation composition, and final end product.

• At elevated pressures, the temperature rise associated with the TSE (at higher rpm) is much higher than for a SSE with lower rpm.

• Accordingly, SSEs are generally better for filtration-intensive processes, as is often a key component in recycling systems.

• Distributed processing with complex sub-systems involves issues such as the various equipment sub-systems (unit operations) to be integrated in the overall system, communications protocols, and experience with integrating disparate systems.

The following are examples PIR and PCR processes where TSEs have been successfully utilized:

Real-World Post-Industrial Reclaim Systems

PET & PLA Edge Reclaim Direct to Sheet: This process has been around since the 1990s and is well-proven in many production systems around the world. The TSE is used to devolatilize moisture from in-house edge trim for PET and PLA formulations (and sometimes PET PCR) to avoid the drying step (and save the associated cost) and minimize IV loss that results from hydrolysis. A big plus is that higher percentages of edge trim can be integrated into the sheet (this generally holds true regardless of the polymer formulation). Here is a quick system overview:

Corotating twins in a tandem setup are used to reprocess post-consumer polyvinyl butyral from car windshields.

Corotating twins in a tandem setup are used to reprocess post-consumer polyvinyl butyral from car windshields.1. Gravimetric blending system for sheet-edge reclaim, virgin pellets, and additives/masterbatch;

2. Metal detection at extruder feedthroat;

3. Corotating TSE process section designed for multi-stage venting;

4. Vacuum-venting system designed for deep vacuum and in-process componentry for maintenance and cleaning;

5. Hydraulic screen changer for coarse filtration (only if some PCR materials are being processed);

6. Gear pump for pressure generation;

7. Continuous screen changer for fine filtration;

8. Sheet and downstream system the same as would be mated to a SSE.

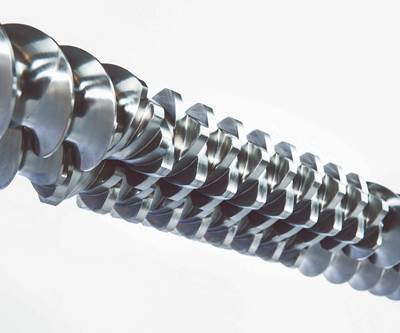

Reclaim Nylon Fibers from Bales: This process has utilized TSE technologies for both compounded pellets and direct fiber production. This process presents a number of challenges, including shredding of bales of fibers so that they can be metered into the TSE, eliminating any residual metal strapping from the process stream, accurately metering the ground fluff into the TSE, and vacuum venting of residual moisture and volatiles associated with the spin finish on the fibers. A system might include:

1. High-volume shredding system that accepts bales and reduces the materials to short fibers;

2. Multi-stage metal contaminant detection stations, including electromagnetic type for both ferrous and non-ferrous metals;

3. Conveying system to a weigh-belt conveyor;

4. High-speed crammer assist device to push the fibers into the TSE feedthroat;

5. TSE process section with multi-stage venting and extended L/D if filler or fiber compounding is performed;

6. Screen changer (see-through ring if formulations include glass fibers or similar feedstock);

7. Downstream systems including:

• Self-stranding pelletizing system: strand die, water slide, pelletizer and classifier;

• Fiber system: booster gear pump, continuous screen changer, multiple spinnerette melt pumps, downstream fiber and winding system.

PCR applications in which corotating twins are utilized include converting used tires into ground rubber particles. Shown here is a setup for such a process, including two side stuffers.

PCR applications in which corotating twins are utilized include converting used tires into ground rubber particles. Shown here is a setup for such a process, including two side stuffers.

Purposeful Degradation of HDPE: In almost every process the goal of the TSE is to mix materials with minimal degradation and maintain mechanical properties. However, the TSE has been used to purposely “beat up” the polymer and increase the MFI (and flow properties) for a subsequent process. A fractional-melt HDPE scrap material is granulated and metered into a TSE that operates at very high speeds (1000+ rpm) with elevated temperature setpoints (100° C higher than normal). The screw design will include high-energy, input-neutral and reverse-kneading elements to impart extreme shear and energy that results in high melt temperature and degrades the polymer (normally to be avoided).

Closely intermeshing geometric tolerances inherent in TSEs often make them unsuited for processing recycled feedstocks with high degrees of contamination.

By using the TSE in this manner a fractional-melt HDPE scrap is modified into a molding grade so that the materials could be reused in a molding process, facilitating close to 100% utilization of the raw materials coming into the facility. The system might look like this:

1. Loss-in-weight metering feeder with a screw and auger configured for regrind;

2. High-speed corotating TSE with a shear-intensive screw design and high-temperature barrels/heaters;

3. Combination screen changer and melt-flow diverter;

4. Water-ring or underwater pelletizing system.

Real World Post-Consumer Reclaim Systems

High-Level Filler Compounding of PCR: Processing HDPE, PE and PP post-consumer feedstock is possible but presents challenges for a TSE. The materials must be thoroughly washed and dried. Filtration will play a key role to make a good product and therefore a single-screw extruder is often preferred, unless mixing or devolatilization is required, in which case a TSE may be preferred. The TSE will also disperse trace minor components of residual polymers (i.e. PVC, PET, etc) inherent with a PCR feed stream, and also mix fillers (up to 80%) and additives to improve product properties. Another benefit is that TSE can remove residual moisture left over from the washing step, which is often problematic from a processing perspective.

A TSE system for this application might include:

1. Individual loss-in-weight (LIW) feeders for reclaim, fillers and additives;

2. Metal contaminant ejection system at TSE feedthroat;

3. TSE with extended L/D and configured for early-stage venting and downstream filler feeding via a side stuffer;

4. Specialty vacuum-venting system for high-level water removal;

5. Oversized screen changer and melt-flow diverter;

6. Underwater pelletizing system with classifier.

Processing Ground Tire Rubber: The technology to convert used tires into ground tire rubber particles is well known, and the amount of available materials is currently unlimited. These particles can be used as a filler (up to 80%) and mixed with EVA polymer to make flooring and profiles or injection molded parts. The EVA is metered into the TSE and melted before the ground tire rubber (also metered by a loss-in-weight feeder) is “pushed” into the process section by a side stuffer (with twin-screw augers), and a gear pump builds and stabilizes pressure to a specialized die. The system includes:

1. Individual loss-in-weight feeders for reclaim, fillers and additives;

2. Multi-stage metal protection;

3. TSE with downstream introduction of tire rubber via side stuffer and LIW feeder;

4. Gear pump front-end attachment;

5. Specialty sheeting die;

6. Three-roll stack with in-line guillotine cutter or profile downstream system.

Another TSE process that utilizes recycled ground tire rubber is a unique devulcanization process developed and patented by Tyromer Inc. where the tire rubber particles are metered into a TSE and conditioned and devulcanized via the injection of super-critical CO2 and high shear from the rotating screws. The resulting devulcanized rubber can then be reprocessed or compounded with other materials.

TSEs disperse trace minor components of residual polymers inherent in a PCR feed stream, and also mix fillers and additives to improve product properties.

Recycling Safety Glass (Car Windshields): Safety glass is essentially a sandwich of two layers of glass with a PVB film sandwiched in between. Just like tires there’s a lot of it. There are established methods to wash and separate the glass and film. A unique tandem TSE process can be used to turn recycled PVB into a value-added product. A system for this application might include:

1. Washing/grinding/separator system;

2. Metering system to TSE with metal contaminant detection;

3. Twin-screw extruder equipped for devolatilization (to get rid of water) and high-shear mixing (to disperse residual glass and minor-phase polymers);

4. Screen changer for filtration;

5. Gear pump to set feed rate to a second TSE;

6. Melt-fed twin screw extruder with metering feeders for addition/mixing of filler, fiber and additives;

7. Vacuum-venting system;

8. Underwater pelletizing system

Twin-screw extrusion is by far the most widely utilized manufacturing process for compounding and devolatilization, and has been validated in 24 hr/day industrial settings for more than half a century. The superior mixing characteristics inherent with the corotating intermeshing TSE make this device superior to others for controlled and repeatable mixing of multi-component formulations. However, closely intermeshing geometric tolerances inherent in this device often make it unsuited for processing recycled feedstocks with high degrees of contamination. An understanding of this reality is a requirement before applying TSE technology as part of a reclaim system.

With that in mind, when utilized in a thoughtful way, the corotating intermeshing TSE can transform recycled materials into a myriad of value-added products and parts. Continued expansion of TSE technology as part of reclaim systems will result in new value-added products that were previously not viable, and will also improve the manufacturing efficiencies of new and existing recycling operations that might benefit from the compounding and venting efficiencies inherent with TSE processing technologies. An understanding of the benefits, and limitations, of TSE technologies is the place to start.

ABOUT THE AUTHOR: Charlie Martin is president and general manager of Leistritz, a leading supplier of twin-screw extrusion equipment for compounding, devolatilization, direct extrusion, pharmaceutical, and other applications. Martin has been in the extrusion industry for more than 25 years, is a member and former chair of the SPE Extrusion Div., and has given 100+ papers at various technical conferences on a range of extrusion topics around the world. Contact: (908) 685-2333; cmartin@leistritz-extrusion.com; leistritz-extrusion.com.

Related Content

Purpose-Built System Enhances Capacity and Flexibility for Recycler

A Boston recycler invested in a turnkey shredding, granulation and elutriation system to expand its plastics reclaim business.

Read MoreFoam-Core Multilayer Blow Molding: How It’s Done

Learn here how to take advantage of new lightweighting and recycle utilization opportunities in consumer packaging, thanks to a collaboration of leaders in microcellular foaming and multilayer head design.

Read MoreExtrusion Technology Extended to Injection, Enabling Up to 100% Regrind Usage

Twin-barrel (shot-pot) press can handle more regrind, offers other benefits to molders.

Read MoreBuilding a Future With Sustainable Compounds

With roots in recycling, Star Plastics produces engineering thermoplastic compounds to meet performance and environmental goals.

Read MoreRead Next

Compounding PLA on Twin-Screws: What Testing Reveals

Twin-screw extrusion is the preferred method for compounding PLA and other biopolymers. But processing PLA is complicated because it’s sensitive to heat and shear. It’s also prone to hydrolytic degradation if moisture is present in molten PLA. Here’s what one machine builder’s trials revealed.

Read MoreWhy It's Crucial to Manage Melt-Temperature in a Twin-Screw Compounding Extruder

Managing and controlling melt temperature and degradation in a corotating compounding twin is critical to achieve process optimization. For compounders, it also greatly influences the ability of their molding and extrusion customers to make high-quality parts. Here are the results of research that illustrate this.

Read MoreBlazing the Trail In Processing PCR for Corrugated Pipe

Just a decade ago, roughly 10% of HDPE corrugated pipes made by Advanced Drainage Systems used recycled material. That number is 65% now, and growing. Here’s how this processor became a pioneer in this field.

Read More