Reactive Extrusion: Industry Icons Impart Their Insights

Three distinguished experts in the area of reactive extrusion shed some light on this process.

Reactive extrusion (REX) is viewed by many as a mysterious—if not scary—segment of the compounding industry. It is an area filled with tribal knowledge. Yet it is also a value-added process segment that savvy compounders can tap into to distinguish themselves from the competition.

What are the challenges? What are the pitfalls? What kind of equipment do you need? To find the answers to these and other questions, Plastics Technology tapped into the expertise of three of the world’s foremost authorities on the subject: consultant Joseph Golba; retired machinery executive Bill Thiele; and Costas Gogos, a long-time author, professor and reseacher in the field.

Plastics Technology: What is your definition of REX?

Joseph Golba: I could argue that chemistry, and therefore reactive extrusion, occurs in virtually all polymer extrusion operations. These chemical reactions are typically undesirable and can include oxidation, hydrolysis, chain scission, crosslinking, etc. that result in degradation and/or other undesirable changes in product properties.

REX Expert: Joe Golba

But when used to produce high-quality commercial products, reactive extrusion may be defined as a process wherein chemical reactions are executed by design, in a highly controlled manner, within typical process time frames, and over long-term steady-state conditions.

Bill Thiele: Reactive extrusion is that part of an integration of processes in which a chemical reaction occurs wholly or partly in an extruder in order to achieve a target end product.

Some of the required process elements (subprocesses) may be staged in the extruder. Others may be done by upstream, midstream, and/or downstream devices. Supporting devices are usually continuous, like the extruder, but might also be batch, whether single or cascaded.

To build comfort with extruders in REX, it might helpful to mentally rename the “extruder” to something like “staging platform for extrusion processes.” Indeed, an extruder’s length and modularity can host sequential configurations according to each subprocess, or unit operation. They enable configuring the critical REX sections of the extruder or “staging platform” and then building the supporting functions along the length of the extruder, coupled with appropriate external devices.

Besides utilizing length, REX is continuous. That virtue, and a third property which might be called “small mass,” improve control, reproducibility, and heat transfer. The latter is explained by the processed material being confined to “small mass” domains bounded by the screw(s) and barrel(s) which provide a high surface-to-volume ratio for mixed materials on wiped surfaces.

The small-mass property also causes the transport distances in mixing to be very short, and therefore potentially more precise. Being longitudinal and small-mass also helps to isolate subprocesses from each other, often using screw pieces serving as “zoning elements.” The other two fundamental, and sometimes overlapping, screw types are flighted (as mostly feeders and drivers) and mixers (dispersive, distributive, or a combination). So, we might think of extruders as sequential “hosting places” to configure the processes that need to happen, rather than as mysterious continuous eggbeaters.

REX Expert: Bill Thiele

Let me illustrate the versatility of extruders, using mashed potatoes as an example. If you added all the milk to the cooked, cut potato pieces and then tried to mix them, it will be hard to get anything but lumpy mashed potatoes. However, if you add just a little milk and mix, then you will open up the potato matrix, after which you may add some more milk to further reduce the potato modulus. Soon the rest of the milk may be added and getting smooth mashed potatoes will be easy. Reactants and components of widely differing viscosities in extruders can often be handled by multiple injections or additions as sequential subprocesses with the same good results. This example, like others, encourage us to think through what we need to do, rather than to fear REX.

Costas Gogos: One can view polymerization reactions as the “structuring” of monomeric molecules into macromolecular structures, and polymer processing as the shaping and “structuring” of polymeric molecules, since it results in functional plastic products of specific macromolecular orientation and morphology distributions. These two processes require very different types of process equipment and are carried out at different manufacturing facilities.

Reactive polymer processing in the broadest sense, and REX, when the reactive processing is carried out in single- or twin-shaft extruders, is the execution of both processes simultaneously, in equipment normally associated with polymer processing. In reactive polymer processing and REX we go either from monomer to polymer, or much more commonly, from polymer to modified polymer. Inline REX completes the process to include the shaping and structuring of finished products.

Extruders, and particularly twin-screws (TSEs), have unique advantages in that they are capable of easy handling—feeding and advancing—of polymer particulates; melting them efficiently and in very short processing times (short axial extruder distances); and carrying out (with proper screw element selection and sequencing) energy-efficient and rapid laminar distributive mixing of the high viscosity melts, so that they mix intimately and uniformly (space-wise) with the reacting species, a prerequisite to completing the reactions in short processing times and producing a uniform product. TSE advantages extend to their ability to achieve good control of temperature and residence-time distribution; to react in one or more stages under appreciable pressure levels; and also to remove volatile unreacted species, or reaction byproducts. Finally, TSEs are very good dragflow pressurization devices and affect easy viscous-modified melt discharge, often using gear pumps to provide accurate, positive-discharge pumping.

REX Expert: Costas Gogos

On the other hand, extruders also have limitations, which must be considered when selecting equipment for a given reacting polymer stream. The two main limitations are difficulty in handling large polymerization heats of reaction associated with monomer-to-polymer reactions, and inherent residence-time limitations if there is need for long reaction times. It is because of these two limitations that only few classic polymerization reactions are carried out in continuous reactive polymer equipment from a monomer feed to a “finished” polymer.

Thus, single-screw and especially twin-screw extruders are uniquely suited and are the equipment of choice as reactors for carrying out polymer chain-modification reactions, which create novel, value-added polymers needed to meet specific product properties and are characterized by rapid kinetics. REX is used to carry out chain functionalization, substituting and incorporating the functional groups needed to impart the desired polymer properties; and chain modification (chain scission, extension, branching and partial crosslinking) to impart desired polymer molten and solid-state properties.

It follows from the above that the equipment in which reactive polymer processing in general, and REX in particular, are carried out are in fact chemical reactors. The performance, design, analysis, and control of chemical reactors have been dealt with extensively in the chemical engineering literature. There are similarities and profound differences between classical chemical-engineering, low-viscosity reactor design and both the equipment and process design necessary for high-viscosity reactors as are used in REX. The main differences between the two are the conditions required for achieving adequate mixing: In low-viscosity reactors, with their turbulent flow regimes, mixing times for achieving composition uniformity are short compared with the characteristic reaction times. But in high-viscosity reactors, in which only laminar distributive mixing flows are attainable, we have to secure efficient, low-mechanical-energy-consuming, distributive-flow kinematics to achieve mixing times that are commensurate with the reaction times of the material components.

Analysis of REX processes requires knowledge and use of the values and ratios of characteristic times of the competing physico-chemical phenomena taking place during REX, namely laminar mixing, diffusion, reaction, and heat generation/transfer.

REX development activity has always been driven by market forces seeking to create value-added polymers from commodity resins. It started in an organized fashion in the mid-1960s in industrial research laboratories with the REX chain scission (“viscracking”) of PP to reduce melt strength and viscosity, producing “spinnable” PP and supplying an ideal grade for the immense diapers market. Much of the early and current work is to be found primarily in the patent literature. Although some publications, both industrial and academic, can be found in the open literature, there is still a good deal of industrial secrecy, because the products of reactive polymer processing are of significant commercial value.

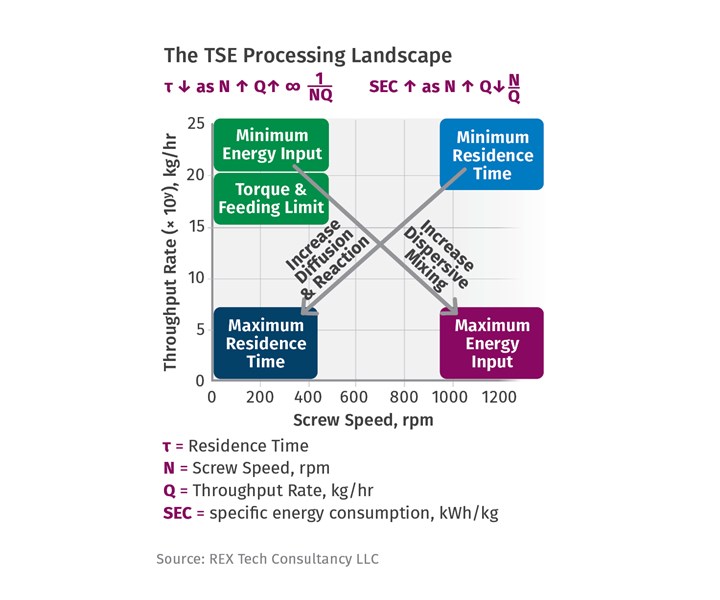

As shown here, decreasing screw speed and throughput rate increase residence time, which is important for reactions whose kinetics are relatively slow. Conversely, increasing screw speed and reducing throughput rate will increase the energy input necessary for the dispersive mixing required in many REX operations. Note: for absolute minimal energy input, the lowest screw speeds and highest throughput rates will be necessary, but these will be limited by machine torque and feed uptake capacity of the extruder. Process optimization yields the appropriate balance of these parameters for the REX processing objective of concern.

As shown here, decreasing screw speed and throughput rate increase residence time, which is important for reactions whose kinetics are relatively slow. Conversely, increasing screw speed and reducing throughput rate will increase the energy input necessary for the dispersive mixing required in many REX operations. Note: for absolute minimal energy input, the lowest screw speeds and highest throughput rates will be necessary, but these will be limited by machine torque and feed uptake capacity of the extruder. Process optimization yields the appropriate balance of these parameters for the REX processing objective of concern.PT: What’s the difference between reactive extrusion and graft reactions?

Thiele: Graft reactions tend to be on the easy end of the REX continuum. If there would be an “REX light” classification, many graft reactions would fit into it. They contrast with polycondensation reactions in REX, for example, whose kinetics tend to put most applications on the hard-to-impractical end of that spectrum.

One can argue that graft reactions, like anhydride functionalizing of olefins, look much like compounding. The melt rheologies don’t generally depart unmanageably from those of the neat polymers. Adding functional groups to a variety of polymers is fairly routine.

Lacking steric hindrance and special factors, graft reaction rates tend to be fast, which makes graft REX cost-effective. High-performance TSEs may have residence times as little as 9 to 15 sec in their barrels, and less in the reactive subprocess sections. The rapid mixing and controlled stress rates accelerate graft reactions to make good use of short dwell times.

Other REX processes are also really fast, like polymerizing PMMA, which can easily get out of hand. Making thermoset powder coatings demands only limited reaction. The extruder must be short, run fast, and generally discharge to rolls. Such reactions, while quick, still tend to be on the harder end of the REX spectrum.

Some reactions are just too slow for REX to be a primary means. The polycondensation reaction of terephthalic acid and ethylene glycol monomers through bishydroxyterephthalate to make PET polyester is one. After 4 to 8 hr in stirred vessels to get the polymer up to extruder viscosities, REX could be tried. For every mole of water removed one can get bigger polymer. At first, it’s easy, but not fast, to vent out the moisture. High vacuum with sequential vents and large amounts of surface renewal under them are needed. Inert stripping might be considered at the last to displace water from the matrix. Even to upgrade polymer, a 62/1 L/D machine can simply run out of venting subprocesses unless the objective is limited.

While the reaction kinetics don’t support REX in making the primary resin, the incremental capability of extruders can support functionalizing PET for special purposes. There’s activity using REX to reclaim, improve or adjust the resin within boundaries, and even to challenge nature itself to remove surface moisture from PET pellets or grinds in the extruder before it can attack the polymer.

Of course, if the material is very valuable, such as for the aerospace industry, low-output REX from an expensive extruder running at low rates could be profitable. So, looking at the reaction kinetics and logistics is very important when considering whether to employ REX.

Some REX can be brutal, but fun. HDPE with 0.2 MFI can be beaten up to become injection moldable at over 3 MFI. Controlled depolymerization is used for many products.

Free-radical polymerization of acrylonitrile and styrene to get SAN works in REX. There are also a variety of polyurethane polymerization and functionalization reactions that work. A few make use of pre-reactors, as do some other REX process trains.

Thermoplastic vulcanized rubber parts can often thank REX. Like many REX schemes, these tend to be a little proprietary. So do reactions with PLA (polylactic acid) and functional modifiers for special purposes.

REX is part of soy and starches being grafted to polymers to make biodegradable composites. Some natural materials are processed at rather cool temperatures.

Peroxides play a role in REX. They can accelerate grafting, help with crosslinking (common with olefins) and can be a part of modifications involving PVOH and EVOH.

Gogos: Graft reactions carried out in REX produce chain-functionalized polymers or graft copolymers. They are of great technological importance since the resulting products are used as compatibilizing agents for immiscible polymer blends and adhesive layers between polymer-polymer coextruded surfaces.

As examples, saturated polymers are commonly carboxylated with acrylic acid (AA) monomer, which is itself polymerizable, since the reaction takes place in the presence of a free-radical initiator. The result is a graft copolymer, where polyacrylic acid is simultaneously produced and grafted onto the main polymer. Common saturated polymers-forming copolymers with AA are HDPE, PP, and ethylene-propylene copolymer (EPR), the last being itself a grafted elastomer. All are blend compatibilizers: HDPE—g—AA, PP—g—AA, and EP—g—AA. Producing these copolymers through reactive processing is the only reaction route available, because copolymerization between AA and the olefin monomers is not possible, since the polar AA reacts and inactivates the metal-based olefin polymerization catalysts. And, regarding the importance of polymeric compatibilizers: Of all polymers sold, about 30% are in the form of compatibilized immiscible blends.

PT: What direct experience have you had with these processes?

Golba: Over a career that spanned over 40 years, I participated and/or led a number of REX-related process developments, optimizations, and troubleshooting. These include:

• Anionic polymerization of nylon 6 using a counterrotating, non-intermeshing (CRNI) TSE in collaboration with Russ Nichols at Welding Engineers.

• In-situ anionic polymerization of nylon 6-organoclay composites using a counterrotating, non-intermeshing TSE in collaboration with Chris Tucker at NFM Welding Engineers.

• In-situ anionic polymerization of nylon 6-carbon nanotube nanocomposites using a counterrotating, non-intermeshing TSE.

• Studied functionalization of polyphenylene ether (PPE) using a corotating TSE as the first step in a reactive compounding operation for a nylon-based engineering thermoplastic.

• Nylon 6 chain extension and melt-rheology modification in a nylon 6-organoclay nanocomposite using a corotating TSE.

• Functional copolymer generation from polymeric moieties via chain scission and insertion using a corotating TSE.

• Polymerization of cyclic butylene terephthalate (CBT) using a corotating TSE.

Gogos: REX—a term coined in the late 1970s by Prof. Joe Biesenberger, my close Polymer Processing Institute (PPI) colleague—has been an activity in which I have been engaged actively for 40 years. The work has been on behalf of polymer industry clients of PPI, collaborative with them, as well as polymer processing equipment manufacturers, such as Leistritz, Coperion, and LIST.

The methodology developed at PPI to explore the feasibility of carrying out particular REX chain modification reactions commences with the determination of the isothermal reaction rates at various temperatures, using laboratory-scale batch internal mixers and monitoring the time-evolving torque, indicative of the functionalized melt evolving macromolecular changes.

Reaction time in batch reactors corresponds to axial continuous REX axial position, following melting—assuming, of course, that the needed degree of melt-distributive laminar mixing has been achieved in both. Calorimetry is used to determine the heat of the reaction(s) involved. The information generated includes temperature and reactant-concentration dependent reaction rates, temperature and extent of reaction-functionalized melt viscosity, the heat of reaction, together with characteristic times of laminar mixing, diffusion, reaction, and heat generation/transfer. These data provide a great deal of assistance in designing pilot and production REX equipment and processes, working in conjunction with polymer processing equipment manufacturers.

PT: What type of equipment is needed? Upstream? Type of extruders? Filtration? Downstream?

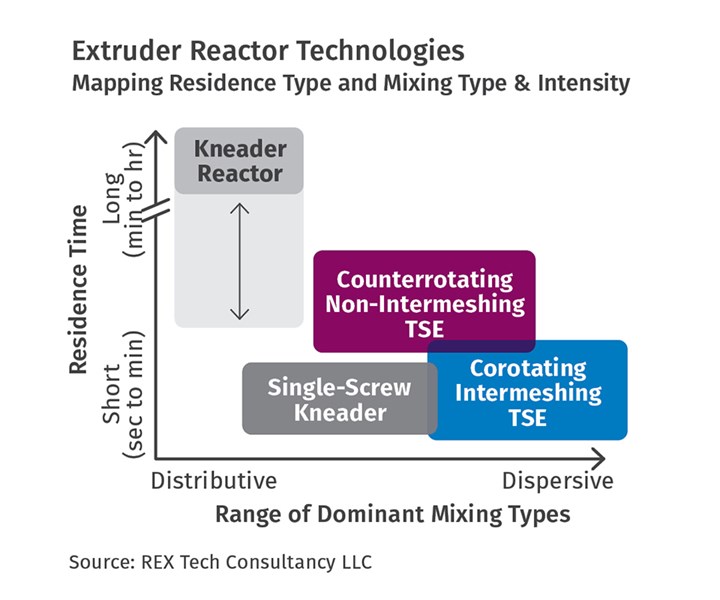

Golba: This depends on the type of REX operation being considered. The first consideration is the type and L/D of the extruder. For many REX processes—e.g., grafting, functionalization, reactive compounding, and even some polymerizations—the corotating twin with an L/D of 40:1 to 60:1 is quite applicable. For REX operations that are encumbered by relatively slow chemical kinetics (e.g., many polymerizations) or the need for multiple stages (e.g. some in-situ polymerization of nanocomposites), the counterrotating, non-intermeshing TSE where L/D can be as great as 120:1 may prove beneficial. The type of mixing required also has an influence. For a high level of dispersive mixing, the corotating TSE and the single-screw kneader seem to work best. Alternatively, where distributive mixing is critical for success, the counterrotating, non-intermeshing TSE provides this in a “global” manner—that is, all along the screw.

For many REX processes, the chemistry must be executed in the absence of water and, in some cases, the absence of oxygen. This situation (not all that uncommon) calls for upstream raw-materials treatment (drying and, if necessary, inert-gas sparging) and management (getting it to the extruder in the desired state). It also calls for properly blanketing the extruder, its feed ports, and feeder hoppers and screws.

Another upstream concern is that of dosing some materials (e.g., catalysts, functionalizing moieties, etc.) at very low rates (e.g., <1%). This can be especially troublesome at the lab scale, where a lot of initial exploratory work gets done and where total throughput rates can be on the order of 5 to 10 kg/hr. This will likely call for mixing the very minor component with a more major component so that dosing is both precise and accurate. This may require grinding solid materials to enable a uniformly mixed and flowable feedstock or using a static mixer just above the feed port for liquid feedstocks.

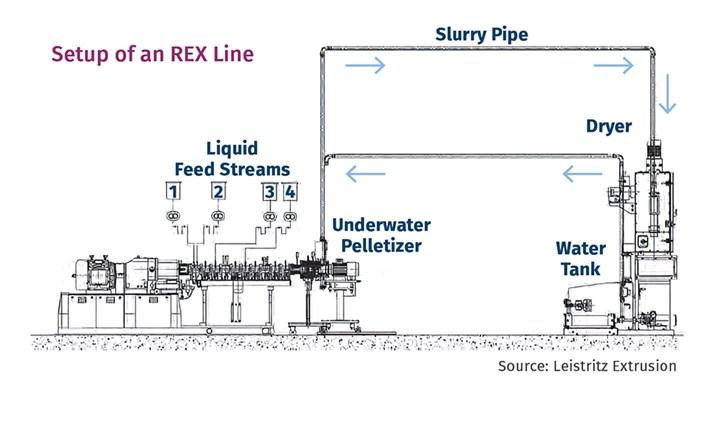

Downstream equipment will depend on the extrudate’s or product’s nature and any specific environmentally related requirements. For example, whether it is hard or soft dictates stranding and cutting vs. die-face pelletizing. If the product is water sensitive, waterless cooling (e.g., cooling belt) may be required, or quick removal of the cooling water (e.g., strand and/or pellet driers). All of this is very similar to what must be considered for melt compounding and other extrusion operations.

Filtration can be important for at least some operations. An example that comes to mind is the production of silane-grafted crosslinkable PE. Silane plateout on the screws and barrels, which ultimately spalls off into the product, can be (and often is) a source of contamination that is very detrimental to the product’s performance. Filtration keeps this contaminant out of the product and, with proper instrumentation, indicates when it is time for extruder shutdown and cleaning.

Thiele: While simple REX might be done on a compounder’s basic production line almost as is, serious processes generally need a modern TSE. It’s helpful if one or more vents or downstream feed ports (bulk and liquid) are available.

You may need to trap and recover free reactants and harmful vented components before the vacuum pump(s). You might require scrubbers and a waste-material plan. High vacuum levels require oil-sealed pumps, which are sensitive anyway.

Multi-stream feeding demands precision gravimetric feeders, more than with routine compounding. When one stream is tiny, like 1% or less, feeding can be a challenge. To make that stream bigger, combining it or diluting it with an inert component that can be removed in situ can be helpful.

When injecting liquids or gasses, accurate, tight pumps and ports are critical. Injectors should deliver from very rigid, small lines onto high-mixing-rate screw elements to minimize surges and ponding that could seriously flaw the subprocess.

When monomers or flammables become involved, explosion-proofing may spectacularly increase the cost and permits for a production line. Corrosion-resistant alloys, if needed, are costly, too.

Some processes deliver pellets, which will require stranding or various melt pelletizing. Others may extrude to form a finished sheet, film or shape. Wire with crosslinked-PE insulation requires a crosshead die at the extruder and support equipment. Powder coatings may go to chilled rolls and crushing to become powder.

Whatever the REX process, it’s important to tie everything together with monitoring and control. This should extend from material transfer to the line’s components, environmental devices, quality control and archiving in order to certify the product and to troubleshoot problems—ideally, before they happen.

PT: Are there any special plant/environmental/safety issues?

Golba: The short answer: It depends. For many operations there will be little in the way of plant/environmental issues. However, there are and will be situations where volatile solvents and/or explosive gases with be used and/or generated that will require close management of these substances and may dictate the use of explosion-rated equipment and facilities.

Thiele: With simple REX grafting there may be only minor changes from conventional compounding, except for the safe handling of peroxides and other components and trapping of materials after vents and before vacuum pumps. MSDS data sheets should be noted. Once a “wet” REX with monomers or flammable matter is introduced, special ventilation, safety practices and even explosion-proofing may be required. These things are very dependent on the specific process and the toxicity of the components.

PT: Are there facilities available to develop REX processes? What universities or research entities have focused on REX?

Golba: I suspect this gets done mostly by those companies where REX work is being done in pursuit of existing and new products, and by extruder OEMs that serve this market. I do not know of an enterprise that focuses solely on the development of REX processes as a primary business model; but that does not mean they are not out there.

Thiele: The Polymer Processing Institute (PPI) at NJIT in New Jersey and the University of Waterloo in Ontario are interested and trustworthy. Many processes are born in the test labs of machinery builders, like Leistritz in New Jersey. The University of Akron was active in this also, as was the Research Council Canada at Boucherville, near Montreal. Due to the proprietary nature of these projects, many are incubated internally, often with the help of trusted consultants.

Gogos: Industrial R&D Labs, despite the reduction in their corporate budgets in recent years, are still developing REX processes, dictated by market and competition forces. University-affiliated independent R&D institutes, such as PPI at NJIT, are equipped methodologically and equipment-wise to develop REX processes. Foster Corp., a Connecticut-based compounder, and the Research Council Canada are also capable organizations for such work. So are, quite likely, university-affiliated polymer laboratories such as Univ. of Akron, Univ. of Waterloo, McMaster Univ., Case Western Reserve, and UMass-Lowell. Finally, in PPI’s experience, the burden of developing the actual REX process often falls on the shoulders of the customer-service labs and personnel of equipment manufacturers.

PT: Are there any REX toll facilities?

Thiele: The propriety nature of many REX processes seems to cause them to be brought inhouse. The exception is simple REX light grafting and similar jobs that toll compounders can pretty much do with only minor reconfigurations.

PT: Can or should compounders consider expansion into REX? If so, how?

Golba: Yes, and some already do REX processing. Indeed, when I was with GE Corporate Research & Development and GE Plastics (now SABIC), we considered ourselves to be among the biggest custom compounding houses, and REX operations were executed (e.g., the reactive compounding to produce Noryl GTX). Another example: Avient (formerly PolyOne) uses REX to produce its Syncure crosslinkable PE.

I believe it is simply good business for compounders to consider expansion into REX. It is a very effective route to new, innovative, and proprietary products that can put them into commanding competitive positions. Also note that for many REX operations, these compounders can use existing equipment—as is or with relatively little modification.

Thiele: On one hand, REX processes can be so quirky and different that compounders might or should spurn them, unless there’s a reasonable contract to justify plunging in. On the other hand, many REX processes involve only reasonable modifications from compounding. An argument can be made to pick a few processes with things in common and market that capability. These can provide some potential relief from low-margin commodity compounding.

PT: Predictions of future trends in the area of REX?

Golba: I see opportunity for growth in the REX area. As mentioned above, it is an effective route to new, innovative, and proprietary products. But at least four things come to mind as necessary for its ultimate success:

• Appropriate equipment and facility assets. This includes extruders and equipment for raw-material dosing and treatment, downstream material handling, and suitable instrumentation (ideally online) for product control.

• An innovative team that couples process engineering and chemistry expertise.

• Process modeling, either inhouse or contracted from the outside, will be of great help for process analysis, development, optimization, and scaleup.

• Technical courage and a “can do” attitude in an enterprise that values and supports such.

Thiele: System controls and documentation will continue to improve and become less optional. They may expand to anticipate and help to prevent problems, to provide total recipe and materials info, to deliver process and quality certification that might be available to customers, to tie into materials’ inventory and supply timing, to give alerts for preventive-maintenance issues, and to do other useful things. Such expectations will be driven by expanding digital resources and quality demands.

REX will become less mysterious to many, who will break processes down into their parts and have the courage to implement them. This is happening and should continue to broaden the use of REX in new ways.

Extruders have such useful properties, but not lots of dwell time. Processes for high-value products may incorporate catalytic zones, increasingly intelligent mixing in critical places, and even tandem REX might be used.

There may be a trend to use naturally derived materials, including ones that are byproducts of other endeavors, which may be functionalized for reactive blending with polymers to create materials with structural, biodegradable or other special properties.

Gogos: Resin manufacturers are very large global industrial conglomerates producing and selling a large number of polymers, grades within a given polymer family, and copolymers. Global resin manufacturers produce a good number of very large-volume commodity polymers, as well as a large number of specialty polymers.

Despite the great number of these commercially available polymers, it pales compared with the infinite number of polymeric (macromolecular) structures possible. This is the beauty of polymers: PE is not a single structure or polymer; it can be polymerized to have myriads of structures of varying molecular weight, molecular-weight distributions, degrees and lengths of chain branching, and degrees and lengths of crosslinking. Contrast this “blessing” to monomeric products: There is only a single member in the sulfuric acid “family!”

Such polymeric structures are attainable utilizing existing industrially available polymers and modifying their macromolecular structures and ensuing properties though REX and reactively compatibilized polymer blend formation in REX equipment. This structure-property-product “customization” by REX is a commercially and technologically desirable development effort and has a sustained future once market need for a given product has been firmly identified.

About the REX Experts: Joe Golba earned a B.S.E. in Chemical Engineering and an M.S.E. and Ph.D. in Engineering Materials from the University of Michigan. In his 40-yr career, he has made contributions in the areas of twin-screw extruder application engineering, process monitoring, and polymer materials engineering. He has led efforts in materials and process development for medical devices, high-performance specialty polymers, and state-of-the art feeder technology. Fifteen patents have been issued representing the novelty and value of much of this work. He now has his own consulting company, Rex Consultancy LLC, providing product focused process development and optimization, especially in the areas of melt compounding, reactive extrusion, and twin-screw extrusion. Contact: jcgolbajr@outlook.com.

Bill Thiele obtained his BS in Chemical Engineering at Purdue University in 1965 and became a research engineer at Johns-Manville and then v.p. of manufacturing & engineering of Precision Polymers, a national plastic pipe producer. In 1976 he was hired to operate Leistritz Extrusion, a subsidiary of Leistritz AG of Nuremberg, Germany and managed the company until 2000. In 2000, Bill retired and became an Episcopal priest at St. John's Church in Passaic, N.J. He still lectures and consults at Leistritz Extrusion. Contact: leistritz-extrusion.com.

Costas Gogos did his undergraduate and graduate work at Princeton University, where he conducted his PhD thesis work under Prof. Bryce Maxwell. He taught in the Polymer Engineering and Science Program of the Stevens Institute of Technology, and co-founded the Polymer Processing Institute (PPI). He is serving as the Board Chairman of PPI and a Distinguished Research Professor at NJIT, participating in industrial and federal R&D. He is a Fellow of the Society of Plastics Engineers (SPE), which has honored him with numerous awards. Contact: costas.g.gogos@njit.edu.

Related Content

Small Batches, Big Success

With no minimum order and an impeccable record of on-time delivery, Precision Color Compounds is becoming a force in the color masterbatch business.

Read MoreMore Than a Compounder: They Have the Science to Create New Custom Materials

Insight Polymers & Compounders leverages its expertise in polymer chemistry to develop next-generation materials.

Read MoreSirmax Adapts Integrated Recycling Approach to US Supply Conditions

Integrating compounding and recycling to leverage untapped postindustrial recycling feedstocks.

Read MoreConfiguring the Twin Screw Extruder: Part 4

For many compounding operations, material is fed to the extruder at the feed throat. This is the case when feeding a single polymer or a blend of polymers mixed with solid additives. Some ingredients, however, present a challenge in feeding. Here’s how to solve to them.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More