K 2004 Wrap-Up on Compounding: Quick Changes and Hybrids Add Versatility

New compounding technologies displayed at K 2004 included some unusual ways to broaden the range of products a twin-screw compounder can make.

New compounding technologies displayed at K 2004 included some unusual ways to broaden the range of products a twin-screw compounder can make. One such machine had a choice of interchangeable L/Ds and another was a hybrid of a twin- and single-screw extruder in one barrel. New pelletizers and dies also em phasized versatility with quicker changes and more wear-resistant surfaces. (Not covered here are new equipment from Berstorff, Farrel, and Henschel that were reported in our show preview in September.)

Quick barrel changing

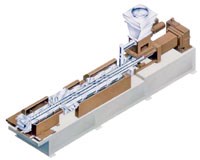

Leistritz in Germany showed the first production-size compounder of any kind capable of automatically exchanging one barrel for another. The idea is that it allows one machine base and drive motor to run a choice of two different L/Ds—e.g., a short barrel for masterbatches and a longer barrel for filled compounds. A 50-mm prototype of the new ZSE-Flex demonstrated the barrel change automatically in 15 min. The ma chine could handle L/Ds from 32:1 to 52:1 powered with the same drive motor, Leistritz says.

Mechanical arms roll one twin-screw barrel section out on one side of the extruder, while other arms insert the new pre-warmed barrel and screws on the other side. Fast hook-up to dies and water lines is accomplished by mounting all water connectors on a single panel. A new water-cooled shroud keeps the barrel surface cool for operator safety as barrels are moved around. Under the shroud, a new barrel-cooling loop has 30% greater cooling capacity. Leistritz plans a full demonstration at an open house March 8-9 in Nurnberg, Germany.

Leistritz also has a new shaft-element joint technology called ZSE Maxx. It uses splines that have a higher OD/ID ratio of 1.66:1 vs. 1.53:1 previously. The deeper splines are also trapezoidal, not triangular, so they conserve more torque and allow more free volume for 25% to 35% higher output, Leistritz says.

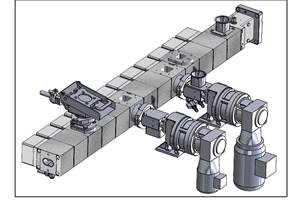

CTE Co. Ltd. of Japan showed its unusual dual-length HTM (horizontal twin mixer), a type of twin-screw compounding extruder. The dual-length corotating machine was actually developed 12 years ago, when the company was called IPEC Co. Ltd. It was renamed CTE (Century 21 Engineering) in 1999. The initial compounding section uses wing-shaped, Banbury-style mixing elements, which knead the material and can incorporate filler levels of up to 70% magnesium hydroxide for wire and cable, 80% wood flour or talc, and 70% titanium dioxide for pigment masterbatches.

Material then passes a barrier section and a vacuum vent before reaching the single-screw extension of one of the two corotating shafts, which builds up pressure before the die. The design reportedly prevents overworking the material and keeps processing temperatures 10° to 20° C lower than conventional twin-screws. The twin-screw part is 28:1; the single screw is 14:1, totaling 42:1 L/D.

CTE also launched a combination of a dry-face and a water-ring pelletizer for wood-filled composites. It's very compact and uses air, water, or both for cooling, depending on wood content. CTE has built models with throughputs from 440 to 1760 lb/hr.

Good housekeeping

C.A. Picard GmbHM of Germany showed an inexpensive device for stripping off screw elements frozen onto shafts. Built in China, the FD-System strips elements from shafts of 25 to 140 mm diam. A unit is installed at Picard's Ohio service bureau.

Coperion Waeschle showed its Fluidcone Blender, a new static mixer for blending free-flowing powders in silos. Internal baffles split the powder flow into four pie-shaped zones around a small, round core zone. It's retrofittable in place of the silo's conical discharge and fits silos from 3 to 15 ft diam.

Dies and pelletizers

Black Clawson Converting Machinery launched a new underwater pelletizer die design for low-viscosity materials such as compounds with high EVA content (up to 40%). The Pelletor has a horizontal die plate and modified heat channels close to the die surface to keep holes from freezing off. The die surface is ceramic coated to insulate it from the water's heat sink. Black Clawson will reface dies (its own or other brands) for water-ring and underwater pelletizers with the high-wear ceramic facing or other facing materials if required.

Coperion Werner & Pfleiderer showed a new SK series quick-change strand die in which the die plate is held by clamping sections on the top and bottom that open with six half-turn screws in stead of fully threaded bolts. The clamps hang on hooks when the die plate is removed.

Econ GmbH in Austria showed underwater pelletizer dies coated with a few millimeters of Ceconid, a mixture of resin and proprietary minerals that is said to be harder than diamond. The first test samples reportedly showed no abrasion after pelletizing glass-filled material.

Related Content

Sirmax Adapts Integrated Recycling Approach to US Supply Conditions

Integrating compounding and recycling to leverage untapped postindustrial recycling feedstocks.

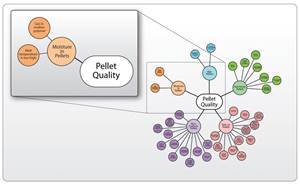

Read MoreThe Path to Pellet Perfection

In underwater pelletizing, numerous variables in the equipment, process and material affect pellet shape, consistency and quality factors such as fines. Defining the “perfect” pellet depends on the conditions of end use, and achieving that ideal requires understanding of the causes of imperfections.

Read MoreStrategically Manage Pressure to Help Ensure Quality in Co-Rotating Twin-Screw Extrusion

Pressure measurement provides an invaluable window into any extrusion process, but it must also be strategically managed at every stage of the process to ensure a quality part is being extruded.

Read MoreMore Than a Compounder: They Have the Science to Create New Custom Materials

Insight Polymers & Compounders leverages its expertise in polymer chemistry to develop next-generation materials.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More