How to Configure Your Twin-Screw Extruder for Mixing: Part 5

Understand the differences between distributive and dispersive mixing, and how you can promote one or the other in your screw design.

The two main types of mixing in compounding are dispersion and distribution. Quite often, new engineers and nontechnical professionals confuse these terms. We will claim we need to improve dispersion when we really want an additive to be uniformly distributed throughout the polymer matrix. Or we will design the screw with distributive mixing elements, but the material tends to agglomerate and needs to be dispersed before it can be distributed.

Let’s explore these types of mixing and how we can promote one type over the other.

When material is fed into the twin-screw extruder, the material falls onto the feed screws as it drops from the feeder(s). For this discussion, we will assume that each material is separate and independent as if being fed individually. In reality, materials may be fed separately via individual feeders or the material might be pre-blended into a single batch.

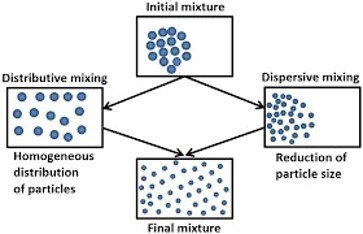

Figure 1 shows how one specific ingredient can be mixed during compounding. Raw materials are fed as the initial mixture. In the diagram, one particular ingredient is shown where large particles of that ingredient are grouped together. We can assume that the white area in the box is the molten polymer matrix. The diagram implies the material is agglomerated into larger particles which have to be broken down and then spread throughout the polymer.

FIG 1 Both distributive and dispersive mixing are needed to produce an homogenous compound.

Source: K. Russell

- Dispersion is the action of breaking larger particles into smaller particles until they are at their ultimate minimum particle size. Dispersion is required to break apart cohesive materials that tend to agglomerate.

- Distribution is uniformly mixing the particles throughout the polymer matrix.

- In a twin-screw extruder, these two mechanisms mostly occur simultaneously but can be tailored to favor one or the other as required.

A material can be distributed but not dispersed. This is shown on the left-hand side of Figure 1. The particles are distributed evenly throughout the polymer but still remain as large agglomerates. This can create uneven concentrations of the additive throughout the material. For a colorant, the part may look blotchy and nonuniform.

A material can also be dispersed but not distributed. The right-hand side of Figure 1 shows the particles have been reduced to their ultimate, minimal size. But they are concentrated in one area of the polymer. This may be due to surging within the extruder, uneven or inconsistent feeding of the additives or a bad premix that is not being distributed by extruder screws.

Of course, we need both dispersive and distributive mixing to produce an homogenous compound as shown in the diagram. Designing the screw with the proper mixing elements provides the correct amount of shear forces to ensure that dispersion and distribution are both utilized when appropriate.

When Dispersion Is Needed

For many compounding operations, dispersion is often not required. Many additives and fillers are already supplied as free-flowing, distinct individual particles. They primarily need to be distributed throughout the polymer to be fully incorporated.

Dispersion is required for materials that tend to stick together in clumps or agglomerates.

Carbon black is one of the best examples of a cohesive material that has a high affinity to agglomerate. Individual particles of carbon black are fused together during the combustion reaction to form aggregates. These aggregates are the primary particle of carbon black and are the smallest size that carbon black can be broken down to during compounding. Carbon black aggregates are held together by weak forces to form agglomerates. The agglomerates must be dispersed within the polymer to produce a compound that fully and uniformly develops the desired black color.

Mixing in Twin-Screw Extruders

The primary elements that are used in a twin-screw extruder for mixing are the kneading blocks. Kneading blocks impart shear forces onto the materials being compounded to mix these materials via dispersion, distribution and homogenization.

Figure 2 shows a typical kneading block. The three key attributes of the kneading block with regard to mixing are the length of the element, the number of discs and the stagger angle of the discs relative to each other. In the picture shown here, the kneading block is 60-mm long and there are 6 discs. Each disc, therefore, is 10-mm wide. If the kneading block was shorter, say 30 mm long, then each disc would only be 5-mm wide. Of course, if the kneading block were twice as long, then each disc would be proportionately that much wider assuming the number of discs is constant.

FIG 2 Typical neutral kneading block. Source: ENTEK

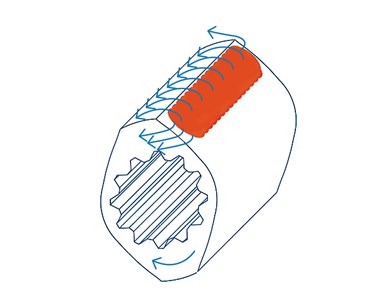

The width of the disc has a direct impact on the shear forces that are imparted to the polymer. Figures 3 and 4 each show an individual disc from a kneading block. The wide disc in Figure 3 forms a pool of molten polymer in front of the disc as it rotates around the screw shaft. The disc plows through the polymer, smearing the materials as it forms a furrow through the material. Shear forces here are quite high which promotes dispersion.

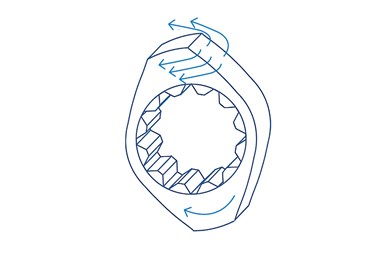

As the disc width narrows, the polymer flows around the disc as shown in Figure 4. The narrow discs of a kneading block slice through the polymer in a scissoring action. This action promotes distributive mixing by essentially stirring the polymer and additives. The melt is divided by one disc and then covered over by another.

Therefore, the first consideration in screw design regarding mixing is the width of the disc. If dispersion is required, then wide discs are beneficial. If the material only needs to be distributed throughout the polymer matrix, then the narrow discs are preferred.

Stagger Angle

The stagger angle is the next consideration when it comes to mixing. The shallower the stagger angle, the more the polymer is conveyed downstream in the extruder. As the stagger angle increases, the forward motion in that area of the screw decreases, causing the polymer to back up in the extruder. As material is held back, the work on the polymer increases because the forward motion of the compound per screw revolution decreases, thereby enabling more intense mixing.

FIG 3 Dispersive kneading disk. Source: Leistritz

When the stagger angle reaches 90 degrees, the material does not move at all due to the rotation of the screws. A 90-degree kneading block is a neutrally conveying element. The forward movement that does occur is due to material being forced from upstream elements that pushes the compound along the extruder.

Reverse pumping elements (aka left-handed elements) pump the material upstream in the extruder against the forward motion within the overall extruder. This balance between the upstream forward conveying elements and the neutral or reverse conveying elements causes the mixing section to be highly filled with material. In contrast, a mixing section that consists of only forward conveying kneading blocks — maybe all 45-degree angle kneading blocks — would have minimal material in this section as it would be pushed out as quickly as it arrived.

It may be tempting to trend toward strong mixing in all cases. Then you can be assured that everything is dispersed and distributed fully. This would be a mistake.

How Much Mixing Is the Right Amount?

The more intense the mixing, the more work that is imparted to the compound. Melt temperature will increase significantly as the amount of work is increased.

- Wider discs generate higher shear forces, which leads to increased melt temperatures.

- A more restrictive mixing section (many reverse or neutral kneading blocks) will cause the compound to be worked more, which again leads to higher melt temperatures.

FIG 4 Distributive kneading disk. Source: Leistritz

- A restrictive mixing section must also be designed to ensure there is sufficient forward motion so the rate is not impeded.

- Likewise, too gentle of a mixing section could result in uneven mixing and poor quality product.

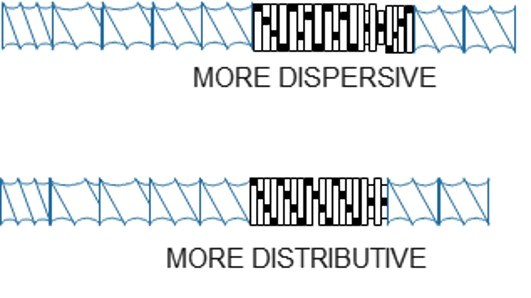

Mixing sections from two screw designs are shown in Figure 5. The top screw is more intense, resulting in a more dispersive characteristic. This mixing section uses wider discs, a larger stagger angle for two of the kneading blocks followed by a neutral kneading block and a reverse kneading block. A design such as this would likely be used with a high loading of a difficult to mix pigment or filler. The bottom design only shows forward conveying kneading blocks followed by a single neutral kneading block. The idea here is to gently stir the additive into the polymer with minimal restrictions. A design such as this might be used when mixing fiberglass or glass beads.

FIG 5 Mixing sections from two screw designs.The top screw is more intense, resulting in a more dispersive characteristic. Source: K. Russell

One point to note regarding the “end” of the mixing section. As I mentioned in earlier articles, screw design is a combination of science and art. Every screw designer will approach a design in a different way. I prefer to end the majority of my mixing sections (>90%) with either a neutral kneading block, a reverse kneading block or even a reverse conveying element (the most severe pumping element). The purpose for this is to ensure the degree of fill in the mixing section is such that the mixing is reasonably efficient.

Some designers will put in a distributive mixing section that consists of all conveying elements. While this design is intended to gently stir the mixture, my experience has shown that this results in a relatively empty mixing section that is inefficient at best. Also, as a result of the low degree of fill in this mixing section, these kneading blocks tend to “whip” the polymer like a beater. This whipping action actually can increase the melt temperature and damage the aspect ratio of certain additives such as fibers.

Mixing sections seem to work more efficiently and more gently when they have a higher degree of fill. This must be balanced against a severe reverse flow that can overwork the material. Balance is the key.

About the Author: Kenneth W. Russell has more than 35 years’ experience working with polymer processing and resin companies. He has expertise in polyolefin polymerization, polymer compounding, reactive extrusion, and film and sheet extrusion. In 2014, he started Optimized Compounds LLC, providing consulting services in reactive extrusion, polymer compounding, new product development, process optimization and scale-up with clients worldwide. In 2021, he joined GEM Plastics, HDPE sheet processor, providing process engineering, operator and technical training, and materials expertise. Contact: kwrcompounding@gmail.com.

Related Content

How to Configure Your Twin-Screw Extruder: Part 3

The melting mechanism in a twin-screw extruder is quite different from that of a single screw. Design of the melting section affects how the material is melted, as well as melt temperature and quality.

Read MoreSirmax Adapts Integrated Recycling Approach to US Supply Conditions

Integrating compounding and recycling to leverage untapped postindustrial recycling feedstocks.

Read MoreHow to Configure Your Twin-Screw Barrel Layout

In twin-screw compounding, most engineers recognize the benefits of being able to configure screw elements. Here’s what you need to know about sequencing barrel sections.

Read MoreStrategically Manage Pressure to Help Ensure Quality in Co-Rotating Twin-Screw Extrusion

Pressure measurement provides an invaluable window into any extrusion process, but it must also be strategically managed at every stage of the process to ensure a quality part is being extruded.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More