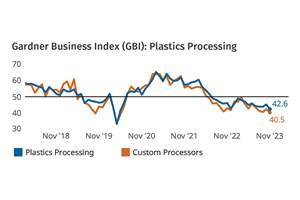

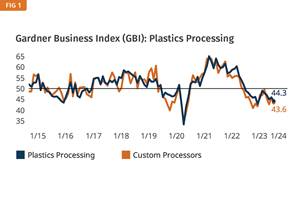

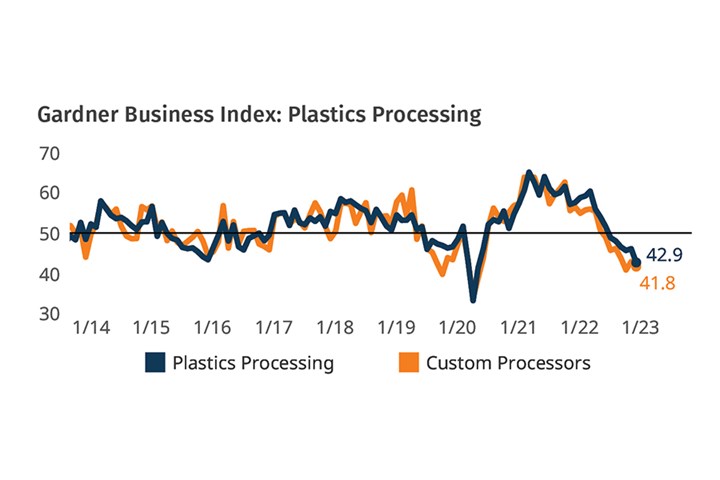

The Gardner Business Index: Plastics Processing for December made November’s break in steadily contracting activity look like a blip. December was down 3.4 points vs. November, more than twice the drop in any previous month of the recent contractionary period, closing at 42.9, a level not seen since May of 2020. The index is based on survey responses from subscribers to Plastics Technology. Indices above 50 signal growth; below 50, contraction.

FIG 1 Activity contracted in a relatively big way for total plastics processing in December, and to a lesser extent for custom processing.

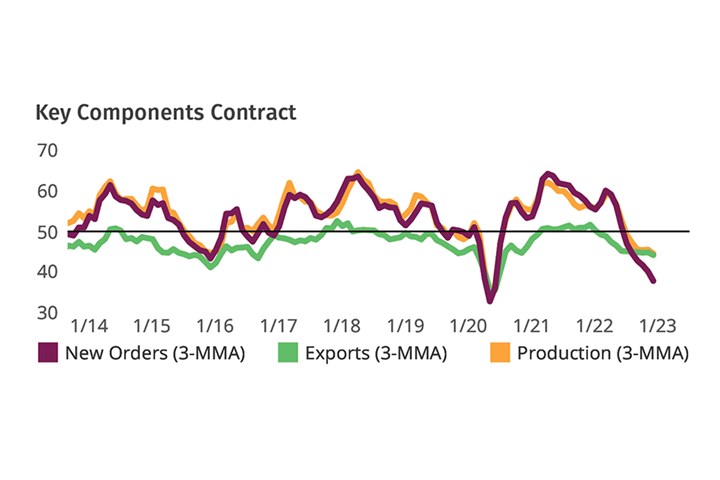

Five of six GBI components contracted again in December, all at increasing rates vs. November. Backlog and new orders picked up the contraction pace the most, suggesting order queues are getting shorter and new orders are coming in slower. Production continued to contract. Less product coming off lines is consistent with declining demand, including that seen in contraction of export activity. Supplier deliveries continued in slowed expansion mode coming off inflated highs due to supply-chain issues rather than strong demand.

FIG 2 Contracting new orders and exports mean declining demand, which drove contracting production activity in December. (3-MMA = 3-month moving averages)

Overall business activity for custom processing contracted at a faster rate again in December, closing the month at 41.8 compared with November’s 43.1.

EDITOR’S NOTE: Finding reliable and relevant data to help guide your business is always important, but especially so during challenging economic times. For this reason, the GBI Plastics Processing Index serves as a great tool for making data-driven decisions. Thank you to everyone who has previously completed GBI surveys. Your participation helped increased response in 2021-2022, making the GBI better than ever because of your involvement. Thank you for your time and efforts and for trusting us to provide you with the latest industry and business insights both in the past and in the future.

If you are a North American plastics processor and would like to participate in this research, click here to begin the process by subscribing free to Plastics Technology magazine.

ABOUT THE AUTHOR: Jan Schafer is director of market research for Gardner Business Media, parent company of both Plastics Technology magazine and Gardner Intelligence. She has led research and analysis in several industries for over 30 years. She has a BA in psychology from Purdue University and MBA from Indiana University. She credits Procter & Gamble for 15 years of the best business education. Contact: (513) 527-8952; jschafer@gardnerweb.com.

Related Content

Processing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MorePlastics Processing Activity Drops in November

The drop in plastics activity appears to be driven by a return to accelerated contraction for three closely connected components — new orders, production and backlog.

Read MoreProcessing Making Slow, Steady Progress

Plastics processing activity didn’t make its way into expansion territory in March, but seems headed in that direction.

Read MorePlastics Processing Business Index Contracts Further

All components dip as index hits low point of 2023.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More