Purified Cellulose Fibers Show Promise In Reinforced Thermoplastics

Purified cellulose fibers could be the next lightweight reinforcements for thermoplastics.

Purified cellulose fibers could be the next lightweight reinforcements for thermoplastics. Rayonier Performance Fibers, a large maker of specialty pulps, is working with the USDA Forest Products Laboratory in Madison, Wis., on reinforcing nylon 6 with cellulose fibers. CreaFill Fibers Corp., a maker of specialty cellulose fibers and powders, is exploring cellulose reinforcement of HDPE, PP, and PVC. Potential applications range from molded auto parts to extruded profiles.

Cellulose fiber is commercially available in bulk with consistent properties and quality. It has several advantages over glass fiber. It’s lower in density, non-abrasive, and less expensive—yet, in a thermoplastic composite it can still offer roughly two-thirds to three-fourths of the strength properties of glass fiber. Refined cellulose starts in the mid 20¢/lb range, and prices can go higher, depending on fiber length, purity and form (loose or compressed).

Pure cellulose is produced in wood-pulp manufacturing. Bleach strips away the wood lignin and hemicellulose and leaves acid-free fibers (about 50% of the original wood content) for paper making and specialty applications. Refined cellulose fibers have long been used in thermoset plastic applications like injection molded wire caps and electrical outlet boxes. But cellulose fibers haven’t been used commercially in injection molded thermoplastics.

Targeting auto parts

Cellulose was originally thought to be unsuitable for processing at the temperatures required for nylon (435 F) because residual lignins and hemicellulose would degrade and char, causing discoloration and strong odors. Rayonier was probably the first to find that purified cellulose—from which 99% of the lignins and hemicellulose have been removed—could be safely melt compounded into high-temperature engineering plastics like nylon 6 and PBT, which have melting points above 435 F.

Rayonier worked with the Forest Products Lab (FPL) under a joint-development agreement and obtained a joint patent in 2001 on the use of more than 80%-pure cellulosic fibers in thermoplastic compounds with melt temperatures above 356 F.

The partners targeted automotive-grade engineering resins like nylon 6 and PBT because cellulose fiber “is expensive enough that the benefit is greater in high-performance engineering plastics than in picnic tables and decking made with polyolefins,” says FPL research chemist Daniel Caulfield.

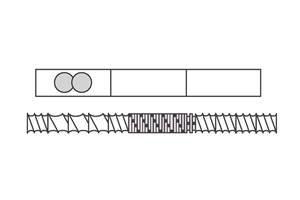

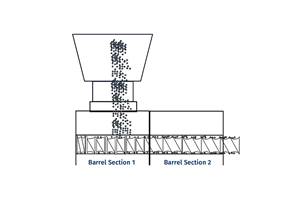

Rayonier and FPL also developed a way to compress the low-bulk-density cellulose fibers into pellets. The Rayonier/USDA patent (#6,270,883) describes production of pellets by compressing a mixture of wet pulp and a binder (sodium carboxymethyl cellulose) into 3- to 6-mm cylindrical pellets using a Kahl Pellet Mill. After drying, the compressed pellets are suitable for shipping in drums or super-sacks. They can be melt compounded in a twin-screw extruder to produce cellulose-filled thermoplastic pellets for injection molding. Loose fibers can also be side-fed into a corotating twin-screw extruder.

Rayonier now markets developmental quantities of its purified cellulose pellets under the name TerraCel 10J for hardwood fiber and TerraCel 20F for softwood fiber. Hardwood TerraCel fibers have nominal average length of 0.04 in. (1 mm), while softwood fibers are 0.1 in. (2.5 mm) long.

The 2001 patent compares injection molded plaques of nylon containing 30% cellulose and 2% coupling agent with plaques of nylon and 33% glass fiber (see table, p. 36). The data show that cellulose fibers perform well enough for many applications. FPL and Rayonier are sampling around two dozen potential customers for this material in Europe, the U.S., and Japan. Most of them are automotive suppliers.

Polyolefin compatible

Meanwhile, CreaFill is working to characterize compounds of its CreaTech TC 750 cellulose fibers in lower-temperature resins—HDPE, PP, and PVC. CreaTech TC 750 fibers have a nominal average length of 0.7 mm and width of 0.02 mm, for an aspect ratio of 35:1.

CreaFill recently published data comparing compounds of 0.5-MI HDPE and 40% CreaTech TC 750 virgin cellulose fibers with and without coupling agents. Injection molded plaques showed a flexural strength of 7570 psi and a reversed notched Izod impact of 2.5 ft-lb/in. When 2% Polybond 3009 coupling agent is added, properties go up: Flexural strength is 7910 psi and reversed notched Izod is 2.6 ft-lb/in. (Polybond is an adhesively modified polyolefin from Crompton Corp., Middlebury, Conn., which performed the tests.)

CreaFill says HDPE/cellulose compounds look promising for applications like roofing membranes, pond liners, carpet backing, and automotive components. Cellulose/PVC compounds are aimed at outdoor furniture, siding, and window and door profiles.

CreaFill offers both wood-derived virgin fibers and recycled cellulose fibers made from paper. Both come in loose form, pellet-mill chunks, or agglomerated micropellets.

Virgin cellulose is pure alpha cellulose, which is stronger than recycled cellulose and can withstand higher processing temperatures (up to 428 F) without charring, whereas recycled cellulose can be processed only up to 392 F.

CreaFill supplies refined cellulose fibers, virgin or recycled, separated by length and purity. These fibers are magnified 200X.

| Cellulose Fibers vs. Glass In Injection Molded Plaques | |||

| Softwood Cellulose | Hardwood Cellulose | Glass Fiber | |

| Avg. Fiber Length, in. % Fiber % Nylon 6 % Coupling Agent Tens. Str., psi Tens. Mod., kpsi Flex. Str. psi Flex. Mod., kpsi Notched Izod, ft-lb/in. Unnotched Izod, ft-lb/in. | 0.10 30 68 2 11,890 783 16,530 798 0.47 4.6 | 0.04 30 68 2 12,620 827 17,690 856 0.47 5.9 | 0.125-0.250 33 67 0 16,100 1160 2111,320 1102 0.85 7.6 |

| Source: Rayonier, U.S. Patent #6,270,883 B1, Aug. 2001. | |||

Related Content

Configuring the Twin Screw Extruder: Part 4

For many compounding operations, material is fed to the extruder at the feed throat. This is the case when feeding a single polymer or a blend of polymers mixed with solid additives. Some ingredients, however, present a challenge in feeding. Here’s how to solve to them.

Read MoreHow to Configure Your Twin-Screw Extruder: Part 3

The melting mechanism in a twin-screw extruder is quite different from that of a single screw. Design of the melting section affects how the material is melted, as well as melt temperature and quality.

Read MoreHow to Configure Your Twin-Screw Extruder for Mixing: Part 5

Understand the differences between distributive and dispersive mixing, and how you can promote one or the other in your screw design.

Read MoreHow to Configure Your Twin-Screw Extruder -- Part 2

Follow these tips to configure your twin-screw elements to promote feeding and solids conveying.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More