Traditionally, retail distribution systems are built for unidirectional flow: from the harvest of raw materials to the manufacturer, through the supply chain to the customer, through the waste-management system to disposal. One of the challenges to implementing a recycling program is redesigning this workflow. For Mainetti, however, that’s nothing new.

Known as the world’s largest hanger company, Mainetti is a supplier of packaging, branding, and supply-chain products to retailers. It’s a global company, based in Italy, with 90 locations on six continents, including three in the U.S., three in Mexico and one in Canada. At Mainetti, circularity dates to the beginning of the “Hangerloop” program in the 1980s. Mainetti realized it was expending time and effort to manufacture hangers that were being used only once and thrown away. The firm established a reuse center and started taking the hangers back from its retailer customers. There, hangers are first inspected for quality; depending on their condition, some are reintroduced to the supply chain; others are ground up and recycled into new hangers. The program has grown with reuse centers in the UK, EU and U.S., and Mainetti now reuses or recycles over one billion hangers per year

The Hangerloop program puts over one billion hangers per year back into the supply chain. (Photos: Mainetti)

The success of the Hangerloop program prompted Mainetti’s leaders to wonder if other materials might offer similar opportunities. Mainetti’s flexible film products, such as polybags and garment shrouds, were also being disposed of or downcycled after protecting retail clothing on its journey through the distribution chain.

“We asked: what can we do to get better use out of this valuable commodity? If we’re doing it with hangers, why can’t we do it with film?” says Keith Charlton, chief operations officer at Mainetti in the UK. “That was the genesis of Polyloop.”

“Polyloop” is Mainetti’s recycling program for circular film packaging. To make the new concept a reality, Mainetti and its partners had to overcome logistical and technical challenges. With its customers, the company needed to build a process for returning used packaging from the distribution chain. With equipment suppliers, the company needed to build a system for reprocessing the returned material while maintaining its valuable properties.

Technical Challenges of Recycling Garment Packaging

Mainetti set out to create a film recycling line for flexible post-consumer packaging, the first of its kind in the UK. The Polyloop project took over five years to move from concept to production, but ultimately succeeded in creating a sustainable loop that produces new clear garment packaging from used clear garment packaging.

Mainetti collaborated with suppliers Erema of Austria and Cadel of Spain to create its Polyloop recycling line.

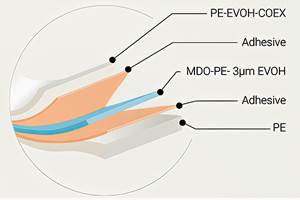

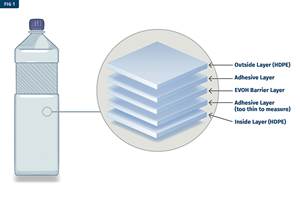

Learning alongside its partners Erema of Austria and Cadel in Spain, Mainetti developed its film recycling system using an iterative approach. Cadel supplied the washing system and Erema supplied the extruder. The lines had to be versatile enough to handle multiple varieties and formulations of LDPE and LLDPE film. They had to be able to deal with materials as thin as 20 microns (0.0008 in.). And they had to be able to remove contaminants from printing and marking. The lines also had to work in concert, so the line speeds and process parameters had to be balanced for operations to flow smoothly.

The thin gauge of garment packaging complicated the development of the Polyloop process. Feeding material of low bulk density into the equipment is a challenge, because so much more must be pressed in per unit weight.

“If you have a very thin and light material coming out of the washing process and going into the extruder, it can be like trying to process feathers,” says Charlton.

The proportion of water weight to material weight is also much greater, creating humidity and process-control issues. The water added by the wash process must be extracted for extrusion. “It’s a fine balance, and as material gets thinner, that balance gets ever more difficult,” says Graham Wilson, group director of operations at Mainetti in the UK.

“We are taking post-consumer waste, very thin gauge, and turning it back into clear material,” says Wilson. “The first line we purchased from Cadel looks nothing like it does today. We changed so many parts due to the experience and knowledge gained while working with them through that period.”

Material that returns from distribution is likely to be contaminated. At various points in its journey, garment packaging often has labels stuck to it, is printed or written on, or otherwise mixed with other materials. This contamination has to be washed out before the film can be processed into new packaging materials.

The washing system must deal with these various contaminants and create a high-purity output. Unlike recycled plastic bags used in grocery stores, for example, clarity is of high importance for retail packaging. Clothes need to be visible through the packaging, and inventory barcodes must be visible to the machines that read them throughout the journey.

After years of design, iterative development, and testing, the line is now running in Wrexham, Wales. Its capacity is 6 million lb/yr.

“When we presented the concept to the market, the reaction was fantastic. Because this deals with a problem a lot of customers have been wrestling with for quite some time,” says Charlton.

Social Challenges to Circular Garment Packaging

Garment shrouds and poly bags protect clothing as it travels from its place of manufacture, often in Asia, through supply chains to distribution centers in the UK or elsewhere. The clothing goes on to retail stores and consumers, while the packaging is usually destroyed. Part of the challenge of implementing Polyloop was reversing that supply chain, returning packaging to Mainetti for recycling.

“Polyloop is not just the equipment. It’s the ability to work with the retailer and then reintroduce this subsequent material back into their global supply chain. That is the trick,” says Charlton.

Segregation of materials is crucial to a thriving recycling loop. The Polyloop processing line can effectively remove ink and other contaminants from the surface of a bag, but it cannot remove color masterbatches. Clear materials can be processed into clear materials, white into white, etc., but mixed-color materials can only be downcycled into other products that will not be likely to be recycled again. This means the engagement of supply-chain partners is very important. Segregation is an extra cost to Mainetti’s customers, but those who have come on board have embraced the process and helped by segregating materials at their distribution centers. And costs are more than recovered through the ability to use more recycled content.

The best results have been achieved with these self-segregated materials. Packaging that travels all the way to the end of the supply chain, whether that be a retail store or an e-commerce delivery, is more likely to leak out of the system. Where possible, engagement at the distribution center stage yields the best opportunity for successful return.

Regulation has helped encourage this kind of engagement. In the UK, regulation came in the form of the Plastic Packaging Tax, which took effect in April 2022. The act established a tax of £200/ton on plastic material containing less than 30% recycled content.

“When we presented the concept to the market, the reaction was fantastic. Because this deals with a problem a lot of customers have been wrestling with for quite some time.”

As a global company, Mainetti needs to consider new taxes, bans, and extended producer responsibility laws that can vary from country to country or even within countries.

“There are a lot of differences in how it’s being applied, but the landing zone they’re all coming to is right around that same level — 30% recycled content,” says Charlton. “People feel they can introduce it there, with a view that in five to 10 years it could be 50% or 60% as the technology improves and as the whole supply chain comes together to address this problem.”

In the future, Mainetti plans to build on the success of the Polyloop program, expanding its recycling operations to strategic locations.

“We hope to take this out from the UK to more areas around the world. And it is more than just the EU and U.S. that are interested, so we see a huge opportunity to scale, and I hope within the next few years we have lines in a number of countries,” says Charlton.

Related Content

US Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

Read MoreGet Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.

Read MoreRecycling Terminology Can Be a Minefield, So We Should Tread Lightly

Loose propagation of terms like “recyclable” and “compostable” has already brought down government regulations on labeling. The plastics and packaging industries should take that to heart with other recycle-related language. Like “monomaterial” for example.

Read MoreMeasuring Multilayer Plastic Containers Made Easier With Today's Ultrasonic Gauges

Ultrasonic gauge technology has evolved to simplify measurement of very thin layers in plastic containers. Today’s gauges with high-frequency capabilities and specialized software can make multilayer container measurement quick and easy for ordinary users.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More