Rockin’ Reunion For Alumni of World’s First, Biggest Thermoformer

In one room, several centuries of experience at the granddaddy of all thermoformers.

With a Chicago blues band laying down the beat, some 50 former employees of Plastofilm Industries and an equal number of spouses, family members, and companions gathered in April for a first-of-its-kind reunion in the thermoforming world. The gathering, held at the Herrington Inn & Spa in Geneva, Ill., was quite possibly unprecedented in all of plastics processing. That’s because Plastofilm occupies a special place in plastics history. It is reputed to have been the first thermoforming company—perhaps even the inventor of the process—and was by far the largest in its time and for decades thereafter.

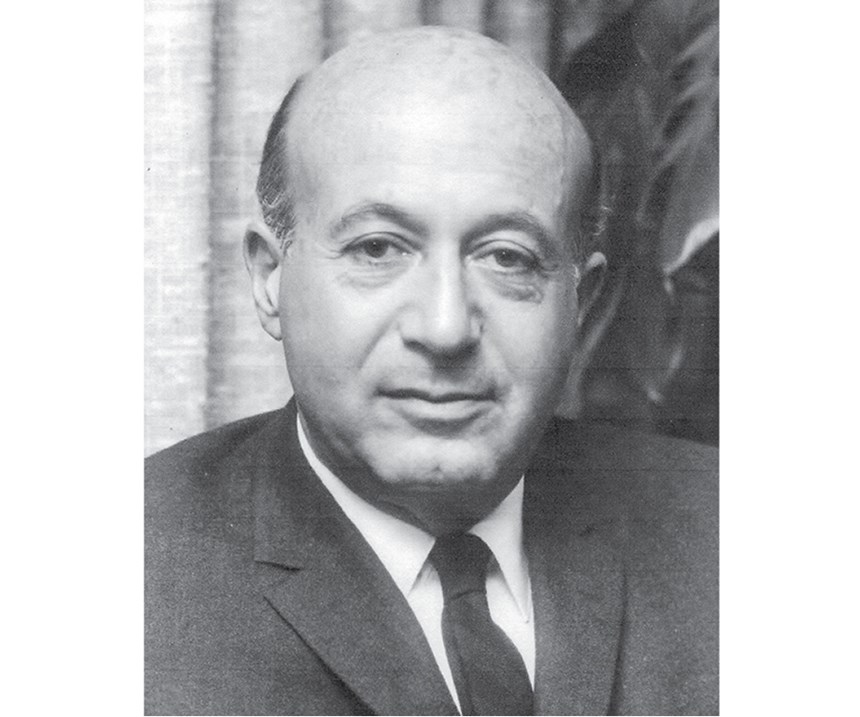

Plastofilm was started in 1941 by George Wiss, an engineer who emigrated from Yugoslavia in 1939. He started out with a contract from the U.S. Army to recover the silver oxide from sheets of photographic film of bombing missions during World War II. He was left with a pile of clear cellulose acetate butyrate sheets to discard and wondered if they could be reused in some way. That reportedly led to the invention of the first vacuum forming machine and process (Wiss was co-author of a patent). The first application was boxes to hold corsages for big bands like Glenn Miller’s that played on Chicago’s Navy Pier.

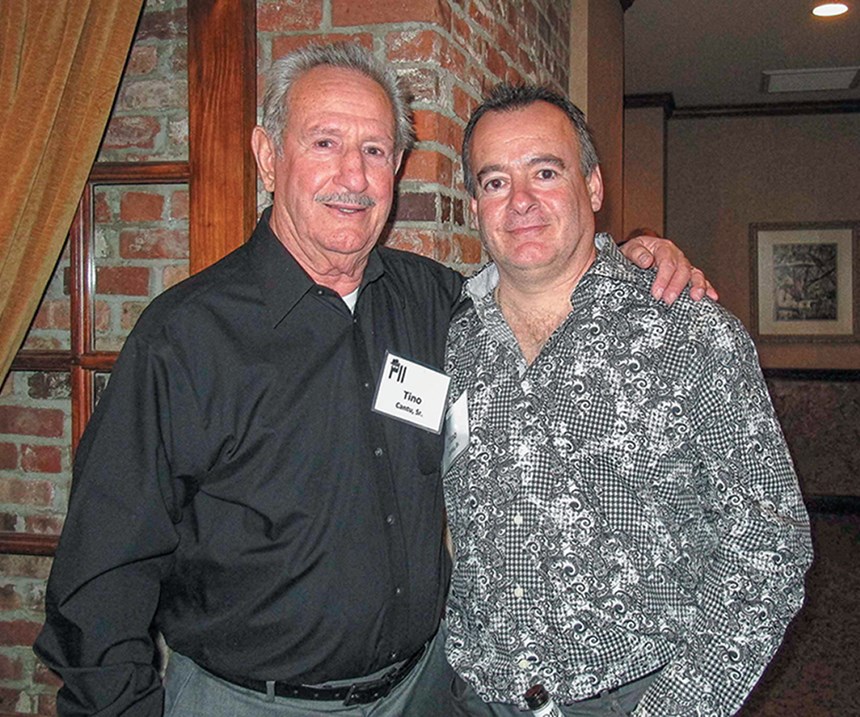

Tino Cantu, one of the most senior “alumni” at the reunion party, worked as a setup man and technician at Plastofilm from 1961 to ’81. He can remember the old days of cleaning silver off x-ray film, which followed after the war ended. He has worked at another thermoformer, Transparent Container, in Berkeley, Ill., for the last 18 years. His son, Tino Cantu, Jr., also at the reunion, worked at Plastofilm for 25 years from 1982 to 2007 and was supervisor of cutting dies before leaving to start his own cutting-die business, TC Dies.

Based in Wheaton, Ill., Plastofilm started up its first thermoforming production line in 1957 and the first high-speed, inline continuous forming machine (reputedly another original invention) in 1959. Plastofilm began its own sheet extrusion in 1966. By 1996, the firm had grown to five plants on three continents, with 550 employees and $280 million in annual revenue.

Two of its biggest “firsts” were getting into medical thermoforming in the 1960s and continuous forming of carrier tapes for automated assembly of electronics in 1981. “Plastofilm became the medical thermoformer,” says Tony Beyer, who started out as a toolmaker at the company in 1973 and worked his way up to plant manager at the headquarters facility until 1991. “Today, many medical thermoformers have Plastofilm people,” he adds. An example is Nelipak, a firm devoted exclusively to medical and pharmaceutical thermoforming. Based in The Netherlands, Nelipak has six plants, including two in the U.S., and over 400 employees worldwide. Dick Simmons, Nelipak strategic account manager in Cranston, R.I., was at the reunion, because he spent 38 years at Plastofilm in sales, toolmaking, and production.

A second breakthrough for Plastofilm was the carrier-tape business, which has been continued by Beyer, who founded his own company, Tek Pak, in Batavia, Ill., in 1992. Although most of that business, like the electronic assembly work that it supports, has moved to Asia, Tek Pak retains 35 carrier-tape forming lines and is the largest such operation in North America, Beyer says (see last October’s cover story on Tek Pak).

Beyer employs 18 former Plastofilm people. He’s also a customer for the younger Cantu’s cutting dies. Former Plastofilm employees scattered to other companies after George Wiss retired and the company was sold and resold to a series of buyers. After its purchase by Alcoa in 2004, Plastofilm’s fortunes declined dramatically. In 2008, Alcoa sold what was left of Plastofilm—then down to $3 million in sales—to a group of buyers that included Brentwood Industries, a thermoformer and injection molder based in Reading, Pa. Advocating the purchase at Brentwood was Richard Partlow, who had been sales manager and president of Plastofilm during his tenure from 1986 to 2000. Now a consultant in Naperville, Ill., he also convinced Brentwood to sell much of the Plastofilm machinery to Tek Pak.

During its heyday, “There was Plastofilm and there were guys who wanted to be Plastofilm,” recalls John Clark, who started there in 1990. The secret of Plastofilm’s success? “Its incredibly knowledgeable sales force,” says Clark, who is now Northeast regional sales manager for Pacur, a major sheet extruder.

“It was an amazing place. It let you grow and do a variety of things,” adds Sue Foos, who started as a third-shift packer/inspector at Plastofilm in 1981 and then worked in the die shop, model shop, and purchasing until she left in 1999. She now works at Tek Pak, “doing everything from customer service to shipping.” Her parents worked at Plastofilm in its first days, washing film. Her father, Arnold Foos, became plant supervisor. Her husband, John Major, worked at Plastofilm from 1977 to 1990 as a machine operator and die mounter.

The reunion party was the result of two years of planning. It was organized by a committee of six, but the driving force behind it was Tony Beyer. The party had a Blues Brothers theme, “Getting the band back together,” and music by the The Blues Brothers Revue. The choice of band was not accidental: As Beyer explains it, John Belushi (one of the original Blues Brothers musical duo with Dan Akroyd) was a native of Wheaton, Ill., and worked at Plastofilm briefly one summer, because his mother was also employed there.

There were other intriguing details to be learned at the party. For example, Beyer worked as a toolmaker on packaging trays for early products from Apple Computer. One of Plastofilm’s salesmen worked together with Apple founder Steve Jobs on those projects. Another Plastofilm salesman worked with Bill Gates on thermoformed packaging when Microsoft had fewer than 50 people, Beyer recalls. “Lots of neat stories from those Plastofilm days,” he says.

Related Content

Thermoformed Container Keeps Battery Cells Safe

Despite last-minute design changes and other unexpected roadblocks, thermoformer TriEnda works with a key supplier on innovative reusable shipping container.

Read MoreInteractive Training for Injection, Extrusion and Other Processes

Paulson has four in-booth stations demonstrating its various training solutions.

Read MoreOrigin Materials Unveils CapFormer for Producing PET Caps

Factory acceptance test completed at commercial scale.

Read MoreThermoformer Maximizes Productivity with 3D Printing

Productive Plastics has created an extensive collection of 3D printed manufacturing aids that sharply reduce lead times.

Read MoreRead Next

R&D Thermoformer: Tek Pak Is Launch Pad For New Products

Toolmaker and thermoformer takes concepts to production-ready parts in record time.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More