‘RollTrusion’ Mates Rolled Metal & Extrusion

Crosshead extrusion is the typical means of coating plastics on relatively small substrates such as wire.

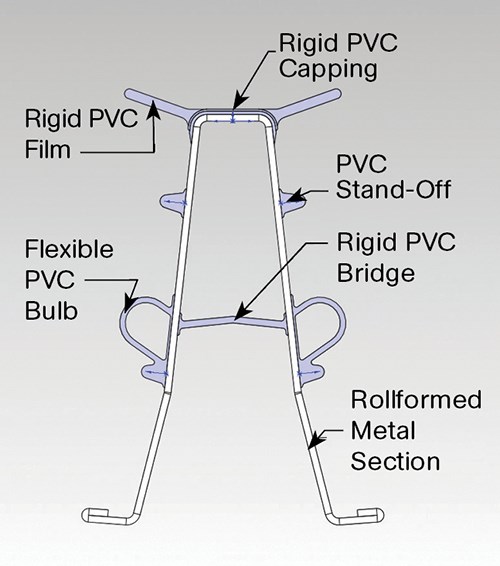

Crosshead extrusion is the typical means of coating plastics on relatively small substrates such as wire. But at NPE2012 in Orlando last month, a supplier of building products discussed utilizing the technology on a much larger scale. Houston-based Quanex Building Products Corp. rolled out RollTrusion, a process that combines roll-formed metal and thermoplastic extrusion in a single part. Quanex has supplied parts made from the process for doors, windows, and a variety of other markets. One key benefit of the process is parts consolidation, states Reed Quanex, business development manager. In one application—a door for a refrigerated cooler used in supermarkets—the Quanex process resulted in a single component replacing four. Quanex is also working to apply plastic to metal studs in commercial buildings to reduce the sound and vibration that normally occurs between metal and concrete.

In the process, roll-formed metal is fed to a specially designed die, and the plastic is extruded around it. Quantex has used PVC, TPE, nylon, and TPU as the coating material.

(952) 250-4967 • quanex.com

Related Content

-

Troubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

-

Roll Cooling: Understand the Three Heat-Transfer Processes

Designing cooling rolls is complex, tedious and requires a lot of inputs. Getting it wrong may have a dramatic impact on productivity.

-

The Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.