Small Machines with Big Technology Portfolio

Boy Machines is demonstrating more technology “bang for the buck.”

Just 13 months into the job of president of Boy Machines Inc., Todd St. Pierre has a message for visitors to NPE2018: “It’s not your father’s Boy machine anymore. We had a reputation for making small, low-cost, high-productivity workhorse machines you could ‘set and forget.’ Today, we are a technology-driven company. Our machines are still economical, but they give a lot more bang for the buck.”

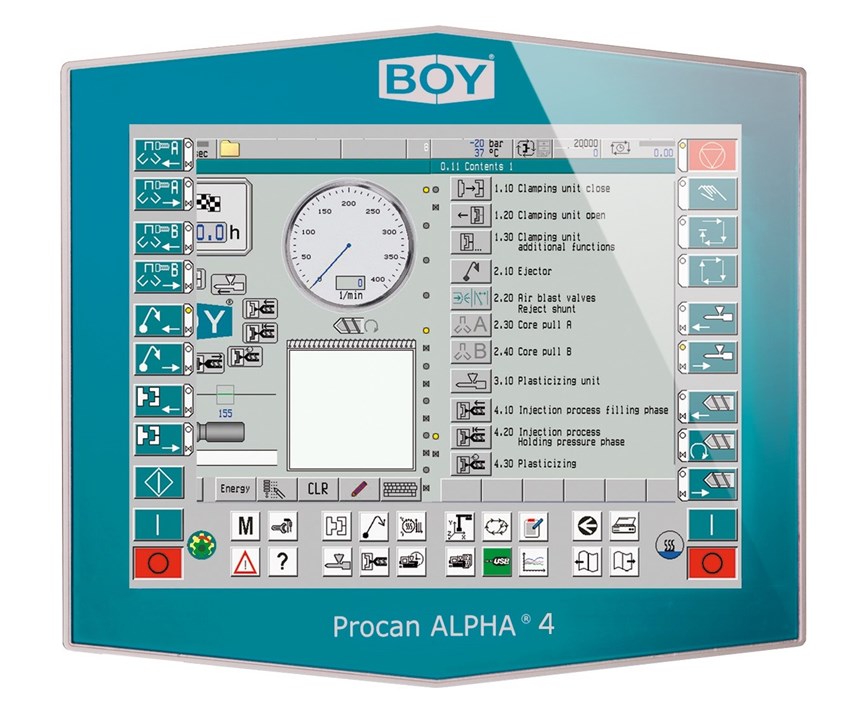

What you get today with Boy technology, St. Pierre points out, is equipment and support for micromolding, insert molding, LSR, multi-component injection, the company’s own new line of robots and pickers, energy-efficient servo-electric drives, and the latest controls—the Procan Alpha 4. That system is faster and more accurate in temperature and position control; offers significantly improved MES functions; and incorporates the OPC-UA communication protocol, which is becoming the standard for Industry 4.0 “smart factory” connectivity.

All of those capabilities are on display in Boy’s booth, W2503. The six machines span the company’s full range, from the smallest (7-ton tabletop model XXS) to the largest (110-ton Boy 100 E). St. Pierre cites LSR as a case in point. “It’s not widely appreciated that we can do LSR, even though we were a pioneer in that field.” But visitors to the booth won’t be in any doubt: A Boy 100 E (110 tons) is molding small LSR cable-end sleeves in a 128-cavity mold with a cycle time of 14 sec. “It’s impressive,” says St. Pierre.

Many U.S. molders will also be seeing for the first time Boy’s new LR 5 Cartesian robot and its three-axis pneumatic picker, both of which are programmable through the Procan Alpha machine controller.

And multi-component injection molders may discover that Boy has auxiliary injection units, the Boy 2C line, which is horizontally or vertically configurable and can be used to convert any brand of single-barrel press to multi-color, multi-material capability.

To shine a spotlight on Boy’s technology offerings, one of St. Pierre’s first projects as president was to outfit a new 900-ft2 processing lab in Exton, Pa., housing as many as five machines for training, trials and demonstrations. He plans to host an open house there this coming fall.

Related Content

-

System Offers 'Lights Out' Mold-Channel Cleaning & Diagnostics

New system automatically cleans mold-cooling lines—including conformal channels—removing rust and calcium, among other deposits, while simultaneously testing for leaks, measuring flow rate and applying rust inhibitor.

-

What to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

-

New Technology Enables ‘Smart Drying’ Based on Resin Moisture

The ‘DryerGenie’ marries drying technology and input moisture measurement with a goal to putting an end to drying based on time.