SPE Announces Winners of Thermoforming Parts Competition

More than 30 parts submitted for annual contest at SPE thermoforming conference.

The Society of Plastics Engineers (SPE) has announced the winners of the SPE Thermoforming Division annual parts competition.

The awards were presented during the Thermoforming Division’s annual conference, held earlier this month in Atlanta. They were presented in 20 categories as well as in a student parts competition. The Peoples’ Choice competition resulted in a tie and the award was presented to two companies.

The categories and winners are:

● Peoples’ Choice: Allied Plastics, Twin Lakes, Wis., for a mobile light tower enclosure, and Plastitel, Chazy, N.Y. for the “pods,” used for the Stryker Isolibrium bed.

The Allied part is a two‐piece enclosure that houses the engine and fuel tank for a mobile light tower. The material is a high flexural modulus TPO with varying color combinations. A starting thickness of 0.275-in. is used for the front enclosure and 0.325-in, used for the rear.

Parts are produced from water‐cooled, cast aluminum production molds. The molds were cast‐oversized, then 100% CNC machined to the customer supplied CAD data. Part orientation on the tool was very critical, as depth of draw versus multiple potential undercut features needed to be addressed. The parts had to be designed with structure, as the plastic enclosures replaced a metal housing. A metal frame was incorporated into the design to help reinforce the new TPO housing.

The new tough, durable shell eliminates the need for painting and is corrosion proof. The TPO housing offers a weight savings when compared to the metal housing that is replaced.

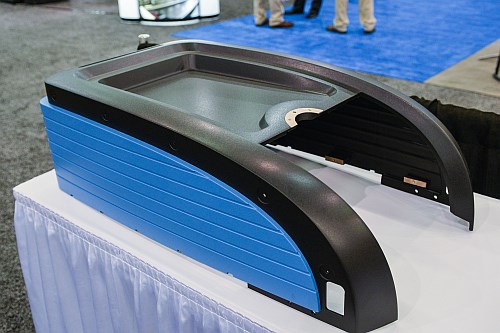

The Plastitel part is a vacuum formed component for the most recent technology offered for patient care in the medical industry. The pod`s role is critical to the success of the 2015 Stryker IsoLibrium Bed (as the main support surface).

The pods are divide into 4 sections individually controlled to maintain the correct pressure needed for the patient. They help the mobility of the patients ensuring regular movement while they are in the bed helping some vital organs function. The pods also help reduce bed sores and improve circulation.

Two major challenges are ensuring a minimum thickness on every individual pod and accurately measuring them. Every vacuumed part is subjected to vigorous inspection.

Material is a custom color blue TPU with a matte finish. The part size is 58 in.x

28 in. x 6 in. with a total of 69 individual pods.

The component is assembled and tested on site prior to shipping to OEM. Custom packaging was design inhouse specifically for the component to ensure its integrity during shipping. The reusable thermoformed cases are disassemble and shipped back to be reused eliminating packaging waste.

● Roll-Fed Consumer-Gold. think4D, Altona, Manitoba (Canada) for the Gillette Venus Swirl.

This project is the first printed and formed blister packaging with think4D technology to be heat‐sealed in a fully automated environment.

Production challenges include the need for very tight tolerances on every packaging component and custom ink formulations to withstand the stresses of the 400 F heat‐sealing process without splitting or cracking. Heat‐sealing flat lids to an arched surface is very challenging and traditionally has higher scrap rates.

This was solved by think4D using their innovative pack‐out system. The multi‐dimensional lids are packed hot right off the thermoforming line onto thermoformed

packing trays and residual heat maintains the desired arc required; resulting in packaging‐line efficiencies, reducing scrap rate while increasing line speeds.

● Roll Fed Consumer–Silver. Placon, Madison, Wis., for the Gillette Fusion ProGlide with FlexBall.

In order to allow easy, no scissors required access to the product without risk of injury to the consumer, a 360° perforation was created around the periphery of a thermoformed PET blister, which is then heat‐sealed to a paperboard insert.

A pull tab, embossed with an arrow at the top of the blister, indicates for it to be pulled downward by the consumer. Using one fluid motion, the consumer can easily separate the blister along the perforations allowing the razor to be easily accessed. Perforations outlining the periphery of the package required complex tooling. The difficulty of perforation tearing was controlled by adjusting stop blocks and changing the height in the tool allowing for the perfect blend of easy (for consumer satisfaction), but not too easy (to ensure product protection) perforated slitting. The ease of opening was designed to extend aroundthe perimeter of the package to allow the blister lid to be smoothly and completely “peeled” off from the bamboo base.

● Roll-Fed Food–Gold. Plastic Ingenuity, Cross Plains, Wis., for the Sargento two- compartment, yin yang tray design. This thermoformed two-compartment tray holds a healthy snack that keeps the ingredients fresh and prevent unwanted mixing of the items.

● Roll-Fed Recycled–Gold. Innovative Plastech, Batavia, Ill., for the Half Pallet Sell-Stack 2L Soda Bottle Dunnage Tray. This half‐pallet sell‐stack reusable dunnage tray holds 40 bottles of 2‐Liter soda products to ship, distribute and display several layers of products in warehouse stores or price clubs without the use of shelving or other structures other than a single 40 in. x 48-in. pallet.

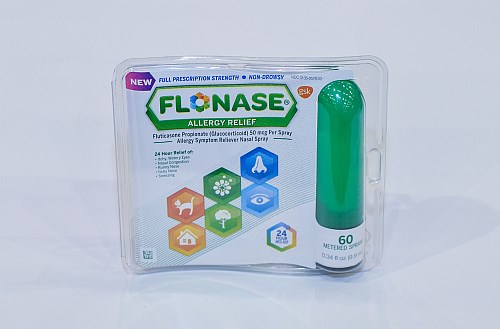

● Roll-Fed Recycled–Silver. Plastic Ingenuity, for the clamshell housing for Flonase Allergy spray. This thermoformed clamshell houses an over the counter nasal allergy relief spray.

● Roll-Fed Innovation–Gold. OMG, Via Torino, Italy, for the Brick Wall Panel. The critical elements of design are the little shapes that made the bricks or the stones because they must simulate the natural aspect of a real brick / stone. The use is to create a paintable wall made of bricks or stones wall panels.

● Heavy-Gauge Vacuum Form–Gold. Plastitel, for the pod medical component (above).

● Heavy-Gauge Vacuum Form–Silver. Medallion Plastics, Elkhart, Ind., for the Aftermarket Hood Assembly for Ford F-150 Aluminum Body OE. The hood assembly replaces the Ford F‐150 Aluminum Body OE Hood.

● Heavy-Gauge Pressure Form–Gold. SMI, San Diego, for the Operating Room Medical Device Assembly. This assembly is for a medical device used in the operating room.

● Heavy-Gauge Pressure Form– Silver. Productive Plastics, Mt. Laurel, N.J., for the diagnostic test machine. The parts are the covers for an automated diagnostic system that checks patient tests results and flags them for doctor’s evaluation.

● Heavy-Gauge TPO–Gold. Allied Plastics, for the Mobile Light Tower Enclosure (above).

● Heavy Gauge TPO–Silver. Brentwood Plastics, Reading, Pa. for the Center Console Assembly. This center console assembly is an example of one item out of 50 part numbers pressure formed out of E3400 TPO, extruded by Primex for a refuse truck interior.

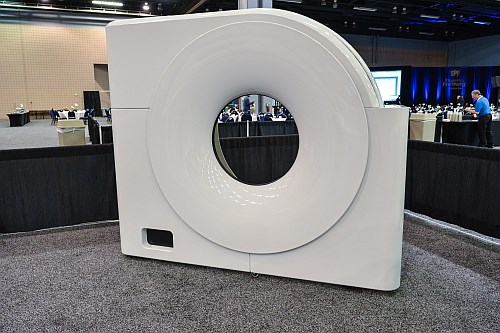

●Heavy-Gauge Value Add–Gold. Productive Plastics, for an MRI assembly. The parts are covers for a medical-scanning device application.

● Heavy-Gauge Value Add–Silver. Kintz Plastics, Howes Cave, N.Y. for the Top cover for medical laser unit. This large pressure formed enclosure is the top cover for a highly sophisticated portable medical laser unit that houses new laser technology used for the removal of tattoos.

●Heavy-Gauge Innovation–Gold. Wilbert Plastics, White Bear Lake, Minn., for a MRI medical enclosure that utilizes temperature controlled positive tooling for vacuum forming and negative tooling with action for pressure forming. Through collaboration with the customer textures, colors, and material selections were developed to meet industrial design expectations.

● Heavy-Gauge Innovation–Silver. Medallion Plastics, Elkhart, Ind., for the Class A Motorhome Dash Top with Automotive Style Stitching. The dash top is a unique design that follows the automotive industry in dash top stitching and is cutting edge in the Class A motorhome market.

● Twin Sheet–Gold. Profile Plastics, Lake Bluff, Ill., for the air duct for medical diagnostic machine, designed to cool critical elements of medical diagnostic machine.

● Twin Sheet–Silver. ATI, Berthoud, Col., for a medical air duct device.These are twin-sheet air ducts formed using the single-oven twin-sheet process.

● Judges’ Award. Wilbert Plastics, for the MRI medical enclosure. See above.

Eight finalists were named in the Student Parts Competition. The student winners are:

First Prize: Kevin Langer, University of Wisconsin, who received a $1,000 award for the “Turtle Caddy.”

Second Prize: David Charlier, University of Wisconsin, who received a $500 award for the “Whirl” Rotating desk organizer.”

Related Content

ExxonMobil Develops High-Performance, 95% PE Recyclable Thermoformed Packaging

The packaging solution involved a collaboration with equipment suppliers Hosokawa Alpine and Multivac Group.

Read MoreCobot Creates 'Cell Manufacturing Dream' for Thermoformer

Kal Plastics deploys Universal Robot trimming cobot for a fraction of the cost and lead time of a CNC machine, cuts trimming time nearly in half and reduces late shipments to under 1% — all while improving employee safety and growth opportunities.

Read MoreThermoformed Container Keeps Battery Cells Safe

Despite last-minute design changes and other unexpected roadblocks, thermoformer TriEnda works with a key supplier on innovative reusable shipping container.

Read MoreIngenuity Is Part of This Former’s Name, and in Its DNA

Plastic Ingenuity started in a garage in 1972 and through a commitment to developing best-in-class products stands today as one of the largest custom thermoformers in the world.

Read MoreRead Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More