Three Friends Team Up For a Second Compounding Venture

When Robert Lapierre, David Valenzky, and Thomas Lacey were in their late 30s and early 40s, the three friends started a custom compounding business to gether.

When Robert Lapierre, David Valenzky, and Thomas Lacey were in their late 30s and early 40s, the three friends started a custom compounding business to gether. They called it Advanced Compounding Services and ran the firm in Cheshire, Conn., for several years until they sold it to another firm. The three entrepreneurs then split up and started companies of their own: Lapierre in sales and plastics consulting, Valenzky in computer controls integration, Lacey in building continuous mixers.

Fifteen years later, after selling out their shares of those businesses to partners, the three got together over beers and reminisced. “When the talk turned to collaborating again, we asked, ‘Do we want to do another company?’” Lapierre recalls. “It was the group of three coming together again.”

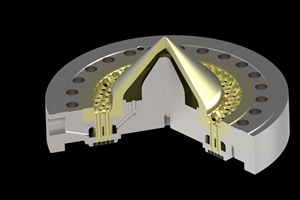

In spring of 2002, the trio decided to take the plunge. Lapierre had an idea for a coextruded pellet that could segregate two reactive chemicals in order to make a better blowing-agent masterbatch. This was the basis for the new business. Phaze II opened its doors in Waterbury, Conn., in September.

Lapierre and Valenzky developed the patented additive concentrates. Lapierre also heads up sales and marketing. Lacey designed and built the coextrusion compounding machinery. Valenzky designed the computer systems and controls.

Besides friendship and complementary skills, the group has years of experience with endothermic foaming agents. Advanced Compounding Services made Hydrocerol additives for Boeringer Ingelheim. When BI built its own manufacturing plant in 1997-98, Valenzky’s company designed the computer systems and Lacey’s firm built the continuous mixers. Lapierre worked in consulting, formulation development, and sales for Tramaco, Nortech, B.I. Chemicals, and other makers of endothermic blowing agents.

Phase separation

Phaze II’s name signifies both the group’s second joint enterprise and its key innovation—phase separation of reactive foaming ingredients. Other endothermic foaming agents are pellets containing sodium bicarbonate and citric acid. Phaze II’s separation of the active ingredients allows use of stronger acids that are more effective at lower temperatures. Low melt temperatures increase melt strength and gas solubility for better foaming and lower densities.

“We tested 25 acids for ones that react at lower temperatures than products already on the market,” Lapierre says. Most of Phaze II’s compounds initiate foaming at 300 to 375 F, but the firm has tested acids that work at 280 F. Since competitors’ foaming systems are less reactive at low temperatures, they have higher carbonate content. The resulting higher pH is hard on screws and barrels, Valenzky says.

Separation of acid and carbonate reportedly gives more control of foaming and lower foam density than with competing products. “Typically a chemical foaming agent produces densities as low as 25 pcf, but we get down to 15 pcf with our standard product and 9.5 pcf with special acids,” Lapierre says.

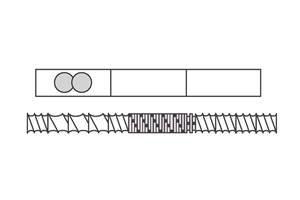

Phase separation is accomplished in two ways. One is a salt-and-pepper blend of single-ingredient (carbonate or acid) pellets. The coextruded pellet is divided down the middle—one side containing the carbonate and the other the acid component.

Phaze II started out offering monolayer Phaze-Cell products in six standard polyolefin and styrenic formulations. Coex pellets will be commercial soon. In a few months, Phaze II plans to offer phase-separated exothermic foaming agents, too.

Losing a partner

Midway through building the coex compounding line that is central to Phaze II’s product development, the team that had looked forward to playing together lost a member. Lacey suffered a heart attack in late January and died a few days later.

Lacey’s son, Tom Jr., has 16 years of plastics-processing experience and had worked with his father on machine designs and start-ups. He quit his job and stepped in to complete building his father’s machine and take over his role in the company. The coex pellet compounding line started production in March.

Related Content

Configuring the Twin Screw Extruder: Part 4

For many compounding operations, material is fed to the extruder at the feed throat. This is the case when feeding a single polymer or a blend of polymers mixed with solid additives. Some ingredients, however, present a challenge in feeding. Here’s how to solve to them.

Read MoreHow to Maintain Pelletizing Quality When Acid Attacks

Developments in the chemistry of polymers and additives have made corrosion a real problem in pelletizers. Here’s how to ward it off.

Read MoreHow to Configure Your Twin-Screw Extruder: Part 3

The melting mechanism in a twin-screw extruder is quite different from that of a single screw. Design of the melting section affects how the material is melted, as well as melt temperature and quality.

Read MoreMore Than a Compounder: They Have the Science to Create New Custom Materials

Insight Polymers & Compounders leverages its expertise in polymer chemistry to develop next-generation materials.

Read MoreRead Next

Beyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More