Extrusion: The Importance of Proper Barrel Supports

Supports that allow the barrel to expand and contract easily will prevent alignment issues. Examine them periodically for proper operation, particularly if you’re experiencing excessive wear.

Increased temperature causes thermal expansion of almost all materials. Thermal expansion results from an increase in the kinetic energy of the material’s molecules that causes an increase in their spacing. The degree of expansion is called the coefficient of thermal expansion. Solid materials tend to keep their exact shape during such expansion and simply change dimensions. Nothing can stop thermal expansion; because it occurs on a molecular level, trying to restrain it is fruitless. In an extruder, particularly a large one, this can be a significant issue.

Although every part of the extruder changes dimensions with increasing temperature, barrels and screws are the most critical components since they generally have the highest degree of thermal change. Since the barrel and screw are made of essentially the same material, their expansions are closely matched and cause no problem. However, their expansion must be considered in the design and use of the extruder, and in any equipment that’s attached to it.

The accepted values for the expansion of steel range from 0.00000611 to 0.00000694 in./in.-°F due to varying molecular structure, but carbon steel is typically 0.00000645 in./in.-°F. That doesn’t seem like much—only 6.45 millionths of an inch per degree of temperature change.

Something is going to move about 5/8 in. to provide for that expansion ... and nothing can stop it.

But if you have an 8-in. barrel that is 240 in. long, with an average temperature of increase of 400° F that adds up to 0.619 in. (240 × 400 × 0.00000645). Something is going to move about 5/8 in. to provide for that expansion ... and nothing can stop it. It could be the downstream equipment moving forward or the extruder moving backward or, even worse, the barrel bending to accommodate the change in length if everything is solidly fixed.

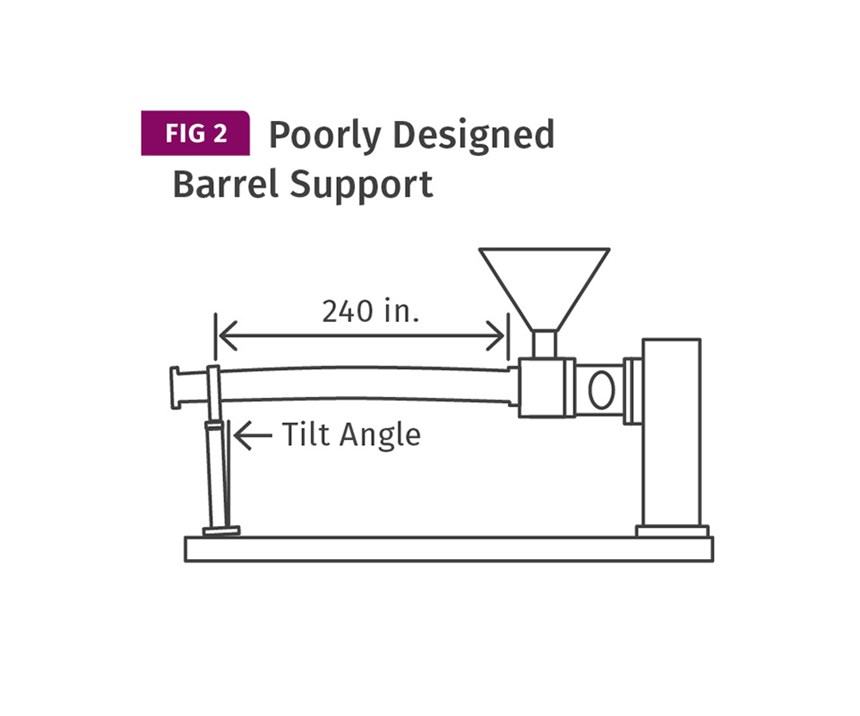

If the barrel cannot expand in a straight line it will bend. This is the cause of many severe wear problems. When the barrel bends, the screw will bend on each rotation to follow the barrel bore. This causes extreme pressure on the flights, resulting in galling of the screw and barrel material and rapid wear. Even very large screws will eventually break from the repeated reverse flexure, just like what happens when you bend a wire back and forth in your fingers.

The first thing to consider is whether thermal expansion can be accommodated by allowing the extruder to move backward, or configuring the downstream equipment to freely move forward. If you’ve done that and are still experiencing thermal-expansion problems, most likely it’s because the barrel supports are not allowing the barrel to slide forward and backward freely as the barrel is heated and cooled. When the barrel cannot slide freely, the expansion force is so powerful that it simply pushes the support over. This can result in varying amounts of misalignment depending on the length of the barrel, the operating temperature, and the design of the support.

The barrel support is simply a cradle to support the weight of the barrel, taking out the natural sag, and to correct any minor lateral deflection. It is not a device to straighten the barrel, which must be straight to begin with in order to put the screw in place.

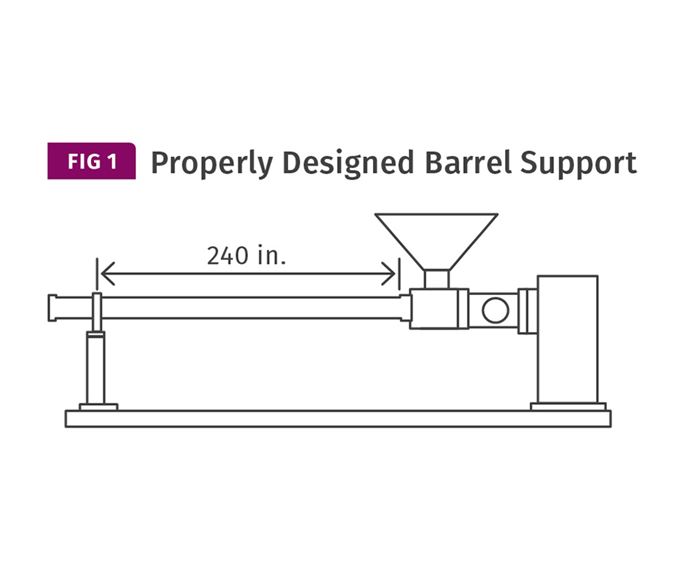

The worst case is when the barrel is rigidly clamped into a ring or halo-like collar and then bolted to the support. This setup can prevent any movement. Even though there may be initial clearance between the ring and barrel, the combination of increased friction from corrosion and the weight of the barrel will often prevent sliding. Figure 1 shows a support that is working properly; the barrel remains straight. Figure 2 shows a support that prevents the barrel from sliding, resulting in the support being pushed over and the barrel bending.

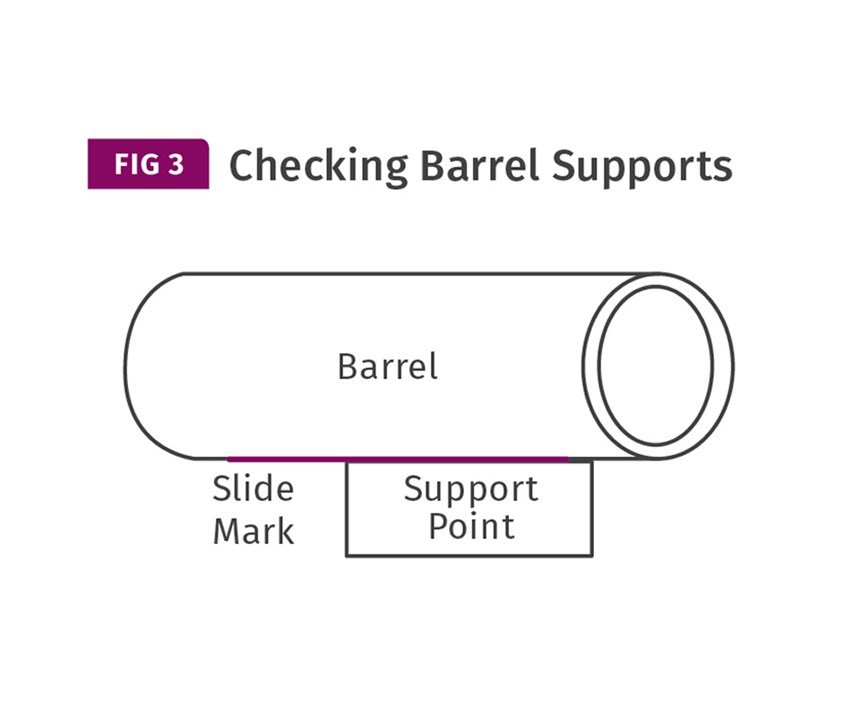

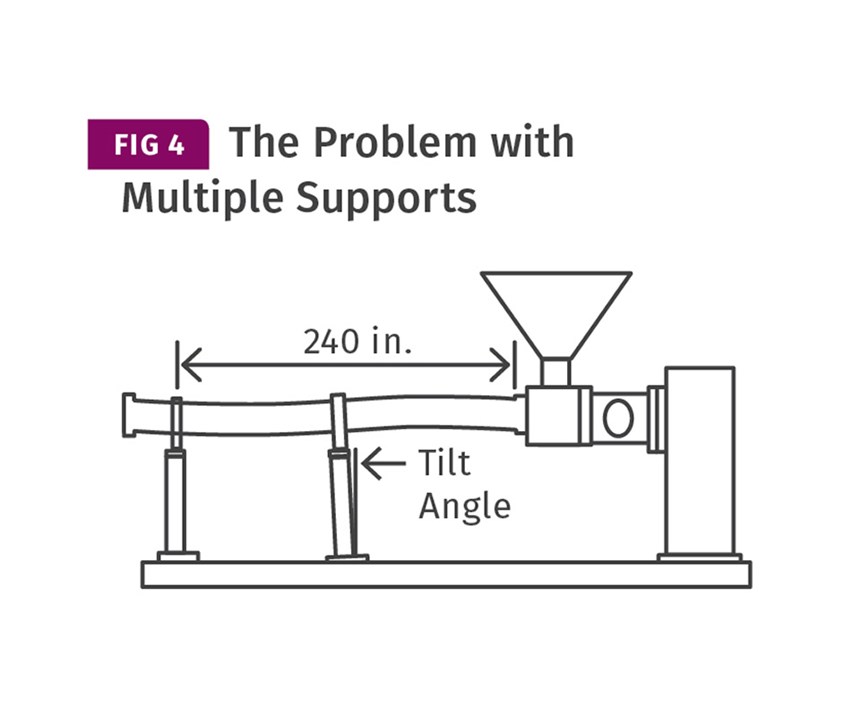

You can check to see whether your supports are working properly by putting a level on the support when the extruder is cold and then checking it again when it’s fully heated to see whether it tilts. Also, you can check the slide marks on the barrel at each support and see whether the movement over the support is proportional to the calculated expansion at that point (Fig. 3). The problems can be more severe when there is more than one support. If each support allows a different degree of sliding, that causes it to distort into a complex bend, which is worse than a gradual bend (Fig. 4). When the total cost of screw and barrel wear from an out-of-alignment barrel is computed, and other replacement parts are considered, downtime and reduced production efficiency can wind up being a bigger expense than what’s considered catastrophic such as loss of a drive or reducer. Maintenance of the supports is an important aspect of overall extruder maintenance but is seldom considered even by the most experience operators when corrective action is very inexpensive.

ABOUT THE AUTHOR: Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 40 years. He is now president of Frankland Plastics Consulting, LLC. Contact jim.frankland@comcast.net or (724)651-9196.

Related Content

Understanding the Incumbent Resin Effect

When you are looking to replace an existing resin with a new one, in trials sometimes the “incumbent” resin will cause gels and other defects. Here’s what to look for.

Read MoreRoll Cooling: Understand the Three Heat-Transfer Processes

Designing cooling rolls is complex, tedious and requires a lot of inputs. Getting it wrong may have a dramatic impact on productivity.

Read MoreWhy Are There No 'Universal' Screws for All Polymers?

There’s a simple answer: Because all plastics are not the same.

Read MoreHow Polymer Melts in Single-Screw Extruders

Understanding how polymer melts in a single-screw extruder could help you optimize your screw design to eliminate defect-causing solid polymer fragments.

Read MoreRead Next

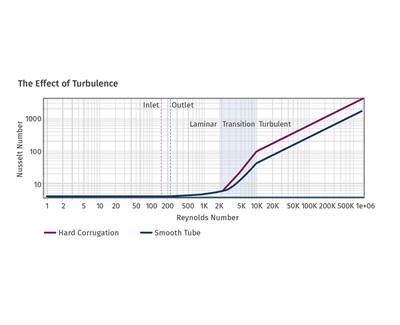

Extrusion Cooling: It’s All About Turbulence

Regardless of what you are extruding, in order to maximize cooling you need to generate turbulence at the heat-exchange surface.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More

.jpg;width=70;height=70;mode=crop)