The New Polypropylenes - They've Got More of Everything

Whether it’s toughness, stiffness, heat resistance, clarity, barrier properties, high flow, or high melt strength—you’ll find more of what you’re looking for in new breeds of PP resins from all suppliers.

The last two years have been a lot more fruitful, in some respects, for users of polypropylene than for makers of the resin. During this time, PP suppliers have struggled under thinning profit margins as they battled huge overcapacity, falling resin prices, and rising feedstock costs. At the same time, however, they have launched a host of new polypropylene resins with a wide range of novel attributes.

New and enhanced polymerization processes and catalysts have spawned PPs with higher impact, stiffness, and crystallinity, a better balance of impact and stiffness, as well as enhanced heat resistance, clarity, gloss, and barrier properties. New grades for extrusion, thermoforming and blow molding are steadily making inroads into non-traditional PP applications. Metallocene grades are taking a wider role, but they are only one part of the story.

Metallocenes move forward

PP made with metallocene catalysts (mPP) has up to now been a niche player in a few specialty markets, but that may be about to change. Three companies now offer isotactic mPP grades in the U.S. and one has just brought the industry’s first syndiotactic PP (sPP) to commercial fruition after years in development. This brand-new form of the polymer was made possible by the advent of metallocenes.

At February’s SPE Polyolefins International Conference in Houston, AtoFina Petrochemicals launched its sPP line, initially comprising three film/sheet resins and one injection molding grade produced in LaPorte, Texas.

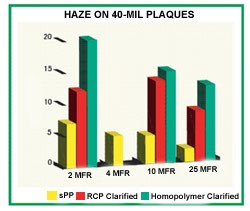

Finaplas sPP resins are copolymers with lower crystallinity than standard isotactic PP. Their unique molecular structure is said to produce exceptional gloss and clarity (see graph opposite), a lower melting point (265 F), and low levels of extractables. These polymers also boast excellent room-temperature impact strength (notched Izod values of 11-12 ft-lb/in.) and are much softer than isotactic PP. Marketing manager Joe Schardl says the latter property suggests roles in competition with other low-melting materials like flexible PVC. Soft sPP is also an alternative to the discontinued Rexflex FPO (flexible polyolefin) family made by the former Rexene Polyolefins before it was acquired by Huntsman.

Finaplas 1251 (2 MFR) and 1471 (4 MFR) are higher-melt-strength grades for blown film and extruded sheet. They have haze values of 6.9% and 4.8%, and a yellowness index (YI) of –3.7 and –1.7, respectively. Both have flex modulus of 50,000 psi and tensile modulus of 70,000 psi. Finaplas 1571 (10 MFR) is for cast and BOPP films. It has a haze value of 4-6%, YI of –2.3, flex modulus of 55,000 psi, and tensile modulus of 71,000 psi.

Finaplas 1751 for injection molding (25 MFR) has a flex modulus of 58,000 psi and tensile modulus of 63,000 psi. AtoFina says all four Finaplas grades can be used for food contact under the provisions of FDA 21 CFR Section 177.1520 C 3.1.

Schardl says sPP also shows potential as a coextrusion tie layer or a compatibilizer in blends of PP or PE with ABS, polycarbonate, or TPU. For that purpose, AtoFina has a developmental functionalized sPP, SM7-001, that is grafted with maleic anhydride.

Isotactic mPP spreads out

Metallocene poly propylenes of the more familiar isotactic type have now penetrated beyond nonwoven fibers into injection molding and films. Stretch-blow molding and thermoforming grades are soon to come.

Advances in mPP may be accelerated by a recent cooperative development agreement between Basell and ExxonMobil. They are sharing metallocene know-how and R&D but not production or marketing.

ExxonMobil currently offers four Achieve mPP homopolymer injection molding resins. These FDA food-contact grades boast higher HDT and flex modulus than conventional homopolymers.

Achieve 1605 is a 32-MFR GP grade with HDT of 201 F at 66 psi and flex modulus of 180,000 psi. Achieve 1615 is a nucleated, 34-MFR resin with HDT of 237 F and flex modulus of 223,000 psi. A clarified grade, 1635E1, has 28.5 MFR, HDT of 241 F, and flex modulus of 230,000 psi. With its low haze (8-10%), 1635E1 is particularly useful for fast-cycle molding of clear articles like thin-wall packaging.

Achieve 1654 is a low-MFR grade for precision molding of small healthcare or electrical parts. This 16-MFR resin has a flex modulus of 225,000 psi and reportedly yields parts with better dimensional accuracy than standard homopolymers.

New developments can be expected from a metallocene catalyst developed by ExxonMobil that enables the tailoring of mPP molecular-weight distribution and produces resins with a fractional MFR similar to those made with conventional Ziegler-Natta catalysts. Initial offerings this year will include homopolymers for film and injection molding that feature clarity, heat resistance, and good stiffness, as well as reactor-made high-melt strength resins for thermoforming and stretch-blow molding, says Exxpol metallocene venture manager George Wagner. Film resins with a better balance of clarity and stiffness may compete with random copolymers.

Basell’s Metocene line of mPPs, newly available in the U.S., now includes four nucleated grades for thin-wall injection molding. Three are homopolymers with unusual combinations of stiffness, high clarity, and low warpage. Metocene X50081 and X50109 are both 60-MFR resins, and X50182 has 18 MFR. They have flex moduli of 220,000 to 230,000 psi, notched Izod values of 0.50 to 0.70 ft-lb/in., and haze of 8%.

The fourth grade is X70293, a 40-MFR random copolymer that boasts improved toughness and “unheard-of transparency” for PP. It has a flex modulus of 160,000 psi, notched Izod of 0.50 ft-lb/in., and haze value of 5%.

These materials exhibit improved optical properties combined with high stiffness, low warpage, and enhanced barrier resistance. Target uses include DVD and CD-ROM cases, containers, and cosmetic articles.

According to Metocene project leader Dr. David Fischer, the next mPPs to surface will be reactor grades with ultra-high MFR. Also in the works are impact copolymers for injection molding, which will combine the optical properties of mPP with good impact strength at below-freezing temperatures.

As we reported in March (p. 30), AtoFina has its own metallocene technology and a family of around 20 Finacene mPP homopolymers and random copolymers for cast film, heat-seal layers, and injection molding. The mPP homopolymers range from 3 to 40 MFR, and 302 to 312 F melting point. Random copolymers range from 7 to 30 MFR and 237 to 297 F melting point. Cast-film grades are aimed at higher-end food and non-food packaging. High-ethylene-content random copolymers are designed for sealant layers in BOPP films. Clarified homopolymer and random copolymer injection grades have scored commercial success in containers and housings for office equipment, replacing clear PS, ABS, and acrylics.

Higher melt strength

Dow Plastics’ new family of specially tailored PPs, trade-named Inspire Performance Polymers, are said to show improved performance and processing characteristics compared with standard PP. Initial products have melt strengths up to 20 times higher than conventional PP, according to global new-business development manager Carlos Ruiz. He says Inspire HMS (high-melt-strength) resins offer drawability up to three times higher than conventional PP resins (see graphs). Better low-temperature impact, higher HDT, and increased stiffness are also claimed.

The first of these HMS resins is Inspire 112, a 0.4-MFR blown-film grade. It produces 2-mil film with dart impact strength of 150 g and 2% secant modulus of 125,000 psi. In coextrusion, it has good clarity for liquid stand-up pouches and bakery-film overwrap. It also has good puncture resistance for heavy-duty sacks, and its melting point above 320 F offers high heat resistance for autoclavable bags.

Two new HMS developmental grades push the performance envelope in other directions. Inspire D 114.01 is a 0.5-MFR grade optimized for blown film and sheet extrusion and high-quality printing. It is said to provide improved stiffness, heat resistance, machinability, creep resistance, puncture resistance, and toughness over competitive polyethylene films. A 2-mil film has dart impact of 120 g and tensile modulus of 184,000 psi. This grade is FDA compliant for use in retort pouches. It also has potential for melt-phase thermoforming of trays, in which it can reduce sag and shorten cycles.

New Inspire D 113.01 is a 0.9-MFR impact copolymer with excellent low-temperature properties and stability over a broad processing window for profile extrusions such as fiber-optic core tubes. It has no-break notched Izod impact at room temperature and a flex modulus of 148,000 psi.

Chisso America also has a new family of reactor-grade HMS resins. “Newfoamer” foamable PPs promote uniform cell structure and are designed for protective packaging, food trays, and soft interior automotive trim. They can also be used as additives to homopolymers and block copolymers to enhance processability and properties.

Novel copolymers coming

In the last year, Basell has developed two classes of PP copolymers. One is the Clyrell family of heterophasic (impact) copolymers for injection molding, which boasts unprecedented combinations of clarity, gloss, and toughness. Clyrell random copolymers for cast film and fibers are said to have unusually low seal-initiation temperatures (252-257 F) and half the usual level of hexane extractables (see PT, Jan. ’02, p. 51). In North America, Basell sources say, “Specific grades are being made available to specific customers for high-end, niche applications.”

Basell will also soon start up in Italy the first commercial-scale unit to use its brand-new, gas-phase loop technology. This Multizone Circulating Reactor (MZCR) process (PT, March ’02, p. 35) is said to be unique in its ability to make more uniform products with advanced performance capabilities. MZCR, which will be retrofittable to existing Basell-licensed Spheripol PP plants, is a step beyond Basell’s multi-reactor Catalloy process. It can be used to make bimodal homopolymers, random and impact copolymers, terpolymers, and special post-reactor blends with improved stiffness/impact balance, heat resistance, melt strength, and seal-initiation temperature.

High-crystallinity grades

AtoFina is using a new Z-N catalyst to make a high-crystallinity blown-film homopolymer (grade 3270) with better processability, barrier properties, and stiffness than its 3276 grade. The new resin has a flex modulus of 560,000 psi, tensile strength of 33,000 psi, and MVTR of 0.2 g/100 sq in./24 hr/mil.

Sunoco Polymers, which took over the PP business of Epsilon Products in late 2001, is developing new PP products for a variety of markets. According to sales director Bill McCann, these include three high-crystallinity homopolymers in the MFR range of 35 to 100. They’ll be aimed at injection molded automotive and appliance parts. F-350-HC, F-600-HC, F-1000-HC are high-stiffness resins with flex moduli above 300,000 psi.

Also new are three 1-2 MFR grades for blow molding and thermoforming of packaging and automotive products. TR-3015-WV, TR-3020-F, and TR-3020-C boast improved processability and good stiffness/impact balance.

Meanwhile, BP is seeking to leverage its Innovene gas-phase process and new high-activity catalyst technology. This process produces PP resins with advantages in flow and toughness/ impact balance, according to venture manager Gary Brooks.

BP has two new high-crystallinity homopolymer extrusion grades with stiffness about 20% higher than conventional PP. In 60% wood-filled plastic lumber, they allow for thinner walls than are possible with HDPE, plus better creep resistance and HDT. A 12-MFR grade, Accpro 9433, has a flex modulus of 350,000 psi and notched Izod of 4 ft-lb/in. Accpro 9346, with 5-MFR, has a flex modulus of 310,000 psi and notched Izod of 6 ft-lb/in.

More high-tech PPs

Besides its work in metallocenes, ExxonMobil also has new Ziegler-Natta (Z-N) catalyst technology, which has produced grades such as PP4792 E1, an easier processing, OPP film grade suitable for food contact. The 2.7-MFR resin has a 1% secant modulus of 119,000 psi MD and 120,000 psi TD, coefficient of friction >1, haze value of 1.0%, and gloss of 89.

Phillips Sumika Polypropylene Co. (PSPC), div. of Chevron Phillips Chemical, has been using improved versions of Z-N catalysts to expand its product slate. One is an enhanced homopolymer for extrusion and thermoforming. Marlex HNZ-02, a 2-MFR nucleated grade, looks promising as an alternative to random copolymers for 4-oz to 1-qt single-serve food containers. Dr. Charles Capshew of PSPC’s Technical Service Dept. says HNZ-02 offers good clarity along with the stiffness of a homopolymer (flex modulus is 230,000 psi).

Other enhanced homopolymers are 2-MFR Marlex HGY-020 and 3-MFR HGY-030, both high-clarity OPP film grades for thermoforming. They are said to permit exceptionally high-speed processing—greater than 1000 ft/min vs. 600-900 ft/min with conventional grades. They have haze values of 0.3% and 0.2%, and gloss of 157% and 160%, respectively.

Two new clarified, high-stiffness injection grades are aimed at containers, large storage boxes, and video-cassette boxes. The 12-MFR Marlex RLC-120 and the 35-MFR RLC-350 are said to have good color (Hunter b value is less than 0) and flex moduli of 180,000 psi and 170,000 psi, respectively.

Equistar Chemicals is developing new products and capabilities with the Novolen dual-reactor, gas-phase process that Equistar and partner ABB Lummus acquired from Basell almost two years ago. One example is a 3.5-MFI homopolymer for extrusion and thermoforming of thin-wall containers and other parts. PPTR522 has an improved stiffness/impact balance, with a flex modulus of 235,000 psi and notched Izod of 0.8 ft-lb/in.

Also new from Equistar is a Novolen-based impact-copolymer compound for high-speed telecom and data com wire and cable insulation. PP4173TS can be extruded at speeds greater than 9500 ft/min vs. 6000 ft/min with previous grades while maintaining excellent conductor centering. It meets the Telecordia OIT aging requirements and can be used as a solid insulation or as the skin layer over HDPE foam for tougher, more abuse-resistant skin/foam structures.

Basell has added SG722, a new high-gloss resin to its line of Pro-fax reactor-grade PP impact copolymers. This is a medium-flow (25 MFR) injection grade designed to replace HDPE in housewares such as drinking cups. It has clarity comparable to HDPE but outperforms the latter in processing speed and physical properties. It has low density (0.90), a gloss rating of 86, drop-weight impact of >61 ft-lb, flex modulus of 152,000 psi, no-break notched Izod impact, and HDT of 200 F.

Boosting flow

Huntsman has come out with a new family of super-high-flow impact copolymers produced with Mitsui’s Hipol gas-phase process and a new-generation Z-N catalyst. These reactor-grade materials are said to have high crystallinity, excellent impact and stiffness balance, and a broader processing window. Initial grades include 100-MFR, medium-impact AP5995 HS (and antistatic version AP5995 HA) for high-speed injection molding of thin-wall dairy and deli containers. With a notched Izod of 0.8 ft-lb/in. and flex modulus of 230,000 psi, they allow molding of 16 to 32 containers every 4-5 sec.

Huntsman’s AP5165 is a nucleated 65-MFR impact copolymer for auto interior trim. It has a notched Izod of 1.3 ft-lb/in. and flex modulus of 175,000 psi.

For high-speed molding of thin-wall food containers, BP now offers Acctuf 3944, a 100-MFR impact copolymer with a good balance of stiffness and impact. It has a flex modulus of 250,000 psi and notched Izod value of 1.1 ft-lb/in.

For molding electronic packaging such as CD cases, Equistar has developed PPTR513, a 65-MFR homopolymer. It has flex modulus of 265,000 psi and notched Izod of 0.2 ft-lb/in.

PSPC has developed new reactor-grade homopolymers with melt flows greater than 100, which will be offered mainly in proprietary compounds.

ICPs are more than tough

The latest crop of impact copolymers are designed for improved balance of flow and mechanical properties. For example, Huntsman has a new 10-MFR, reactor-grade impact copolymer that meets requirements for automotive energy-management systems such as front pillars. New AP7810 has a very broad molecular-weight distribution and is much more shear sensitive than currently used impact-modified PPs with 20 to 30 MFR.

For injection molding, BP is offering 12-MFR Acctuf 3432 impact copolymer with a balance of flow, stiffness (210,000 psi flex modulus), and toughness (2.5 ft-lb/in. notched Izod). It is aimed at crates and pallets, as well as office-furniture seat backs and other applications that require good flow and low blushing, such as housewares, toys, and other consumer products.

For sheet extrusion and thermoforming, BP introduced Acctuf 3140, a 1.3-MFR grade for corrugated sheet and signage. It boasts improved long-term thermal stability, a flex modulus of 185,000 psi, no-break notched Izod impact, and improved printability at higher print temperatures.

Sunoco has two new copolymers with extra-high impact (no-break notched Izod) for consumer and automotive injection molding. The 12-MFR TI-6120-NB and 20-MFR TI-6200-NB are said to have excellent impact/stiffness balance and superior low-temperature drop impact (>28 ft-lb at –20 F).

Another new ExxonMobil development is an impact copolymer for GP injection molding that has significantly better impact/stiffness balance than its predecessor while maintaining its HDT. This PP7032 E2 grade has a 4.5-MFR, no-break notched-Izod impact, flex modulus of 146,000 psi, and HDT of 181 F at 66 psi (see graph p. 57).

Recent developments from Formosa Plastics include impact copolymers with enhanced stiffness and toughness. They are particularly well suited to caps and closures, specialty containers, and automotive trim, says Polyolefins Div. v.p. and general manager Ken Mounger.

Tougher, clearer RCPs

Also new from Formosa are random copolymers with enhanced clarity for molded housewares and other consumer applications.

For extrusion blow molding, BP offers a new clarified version of a 2-MFR random copolymer, Acclear 8239. It has a flex modulus of 220,000 psi, notched Izod impact of 2 ft-lb/in., and a haze value of 11%.

And for stretch-blow molding of small food and pharmaceutical containers, BP is offering sample quantities of a developmental 20-MFR grade with clarity approaching that of PET.

For extrusion or injection-blow molding of juice and beverage bottles, Equistar has developed a new clarified random copolymer with a good balance of clarity and mechanical properties. PP33HF04 is a 2-MFI resin with a haze value of 3-5%.

Huntsman has reintroduced a family of medical grade, random copolymers produced with the Rexene liquid-pool process and fourth-generation Z-N catalysts. According to PP business director Steve Litherland, Rexene 13M11A is a 1-MFR injection grade for pharmaceutical and electronics packaging (e.g., silicone-wafer storage containers). It has a flex modulus of 150,000 psi and notched Izod impact of 1 ft-lb/in.

There are also three Rexene injection, extrusion, and stretch-blow molding resins. Grades 23M2A, 23M2ACS 198, and 23M2ACS 038 all have 2 MFR and a flex modulus of 150,000 psi, plus different additives for packaging particular drugs—including Kosher-grade additives. These resins offer improved stiffness, color stability, and heat resistance that allows for autoclave and ethylene-oxide sterilization.

Related Content

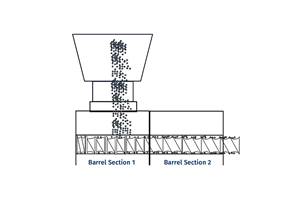

How to Configure Your Twin-Screw Extruder -- Part 2

Follow these tips to configure your twin-screw elements to promote feeding and solids conveying.

Read MoreWhat to Know About Your Materials When Choosing a Feeder

Feeder performance is crucial to operating extrusion and compounding lines. And consistent, reliable feeding depends in large part on selecting a feeder compatible with the materials and additives you intend to process. Follow these tips to analyze your feeder requirements.

Read MoreImproving Twin-Screw Compounding of Reinforced Polyolefins

Compounders face a number of processing challenges when incorporating a high loading of low-bulk-density mineral filler into polyolefins. Here are some possible solutions.

Read MoreMore Than a Compounder: They Have the Science to Create New Custom Materials

Insight Polymers & Compounders leverages its expertise in polymer chemistry to develop next-generation materials.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More