Time to Swap Out Those General-Purpose Injection Nozzle Tips

Still the standard in the industry, GP nozzle tips can cause a myriad of problems for molders. There are alternatives out there that should be examined.

Injection molding involves hundreds of details. Finding and fixing the details costing you money will often make or break a molding shop. The problem is that there are so many details that most of us get lost in the quagmire.

Here we will focus on the often-ignored nozzle tip. Granted, it’s a minor component of an injection molding machine, but it can cause major issues in profit loss, part quality, and production … not to mention processor aggravation. Using the wrong nozzle tip can ruin a molder’s day and make the front office cringe at the profits lost (if they bothered to notice). We will start by listing the issues involved, then detail what needs to be done to make life on the shop floor significantly easier and more profitable.

Here is a partial list of issues resulting from the wrong nozzle style:

1. Poor design/installation:

a. Excessive shots/time for color changes;

b. Excessive heat transfer to cold sprue bushing;

c. Incorrect nozzle contact force;

d. Shorted wires and a hassle and safety risk repairing them;

e. Contamination;

f. Stringing;

g. Personal harm;

2. Poor temperature control:

a. Nozzle drool;

b. Plugged nozzle;

c. Cycle interruptions;

d. Stringing;

e. Shorts;

f. Tolerance/size variations;

g. Machine downtime;

h. Processor aggravation and injury.

I do not have specific dollar values to jolt you into action, but my guess would be thousands of dollars per day. Plus, I do not know how to account for processor aggravation, time loss and human suffering. Talk to anybody who has changed nozzle tips — I bet they have been burned. So where do we start to make your life easier, more productive and safer — and save thousands?

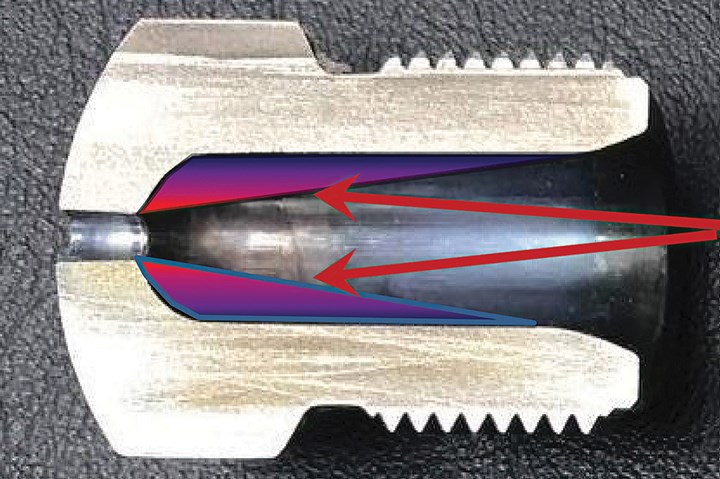

Start with nozzle-tip design. The purpose of the nozzle body and tip is to provide a free flow path for the molten plastic from the end of the barrel to the sprue bushing of the mold. Seems simple, but most molders pay little attention to it and ignore serious design flaws. We will start with the flow path through the most common nozzle tip (Fig. 1).

FIG 1 Note the colored area in this GP nozzle tip. It shows a dead space that causes drag flow, causing resin degradation and purging/changeover problems. (Photos: J. Bozzelli)

Note the colored areas, which are “dead spaces.” This dead space retains the plastic that first fills the nozzle. It stays there throughout production! Molten plastic flows through the center channel. Don’t believe me? Go out to any machine with a GP nozzle tip. Next change the color or resin and then make a few shots until you see mostly the new color.

Stop and safely take off the nozzle tip. Let it cool without cleaning out the polymer inside. Then carefully drill out the plastic in the center from the back end. Start with a drill that is about the size of the nozzle orifice. Clean out the plastic shavings, do not go too fast or too far, as you do not want to scratch the inside of the nozzle. Now look inside. Then go to a slightly larger drill bit; as you increase the diameter of the center channel, eventually you will see the previous color near the side walls. This proves drag flow on the sides.

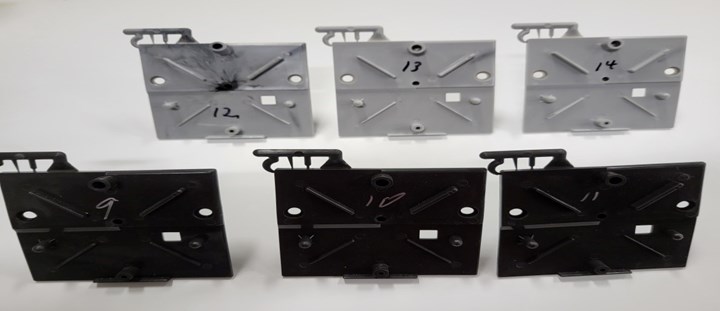

FIG 2 Here are shots 9-14 in a black-to-gray-color change using a GP nozzle tip. These are sequential shots (no purging, but a special screw was used). This illustrates the extended time it takes to transition from one color to the next due to dead spots in the GP tip.

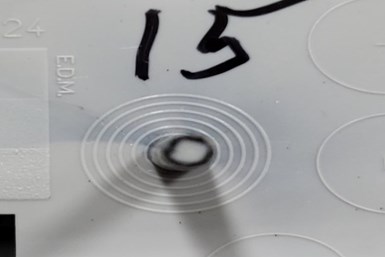

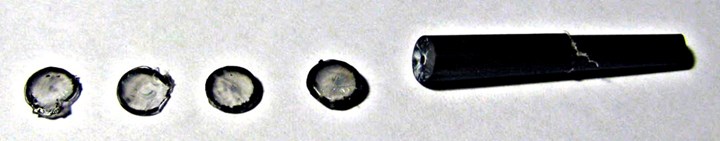

Still not convinced? Check out Figs. 2, 3 and 4, which show a color change going from black to gray. These are sequential shots, no purging but using a well-designed screw.

Figures 2- 4 clearly show that GP tips have dead space that leads to drag flow, which contributes substantially to extended time and extra shots to make color/resin changes. So why are GP tips still the standard in the industry? It’s hard for me to answer without getting profane, but they are the first thing I change when I get on a machine. What should you use? Check out Fig. 5 for a nozzle tip I recommend designed by fellow Plastics Technology columnist Jim Fattori. It is free flow and also great for getting rid of stringing.

FIG 3 Shown here is shot 15 of a transition from black to gray (no purging). The black ring on the outside of the sprue indicated drag flow in the GP nozzle tip.

Another option is to buy what is called a “full-taper nozzle” shown in Fig. 6. It is free-flow and also great for getting rid of stringing. It costs about $5 more than the standard GP tip.

In short, GP tips cause significant issues, which waste:

1. Plastic;

2. Purging compound;

3. Press time;

4. Processor & Operator time;

5. Cleanup time;

6. Cost of waste purge and scrap, plus removal/disposal.

FIG 4 This is a purge study, going from black to clear. Note that the outer ring of the sprue is black, the inner flow channel is perfectly clear. This picture highlights drag flow through a GP nozzle tip.

Because of these issues with the standard GP nozzle tips, I urge you to swap them out as soon as possible for the full-flow or taper version. First,

FIG 5 Designed by Plastics Technology columnist Jim Fattori, this nozzle tip is free-flowing and reportedly eliminates stringing. (Photo: Jim Fattori)

recycle all standard or GP nozzle tips to the metal scarp bin. Then use the free-flow type nozzle tips or if necessary (rarely), the reverse taper.

Check the surface contact of the tip against the sprue bushing to make sure the contact is on the inside of the radius. The best seal is with a small area of contact on the inside radius, but the contact area must be large enough not to peen the sprue-bushing orifice. Contact force is 2 tons to around 6 tons. This is needed to contain molten polymer at 40,000 psi in thinwall applications. In addition, a smaller area of contact will transfer less heat from the nozzle tip to the sprue bushing. It is assumed the injection unit is centered to the sprue bushing. Also, I may have found an insulator that stops heat transfer from the hot nozzle tip to the cold sprue bushing, which I will address in my next column.

FIG 6 Fully tapered nozzle tips like this one minimize dead spaces where material can hang up.

Bottom line: chuck the GP tip, install a full-taper nozzle tip. It is easier and quicker to purge due to reduced dead space. Check it out!

About the Author: John Bozzelli is the founder of Injection Molding Solutions (Scientific Molding) in Midland, Mich., a provider of training and consulting services to injection molders, including LIMS, and other specialties. E-mail john@scientificmolding.com or visit scientificmolding.com.

Related Content

The Effects of Time on Polymers

Last month we briefly discussed the influence of temperature on the mechanical properties of polymers and reviewed some of the structural considerations that govern these effects.

Read MoreFundamentals of Polyethylene – Part 6: PE Performance

Don’t assume you know everything there is to know about PE because it’s been around so long. Here is yet another example of how the performance of PE is influenced by molecular weight and density.

Read MoreHow to Select the Right Cooling Stack for Sheet

First, remember there is no universal cooling-roll stack. And be sure to take into account the specific heat of the polymer you are processing.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreRead Next

How to Prevent Nozzle Tip Leaks, Part 1

Instead of learning from your mistakes, stop making them in the first place.

Read MoreNovel Nozzle Tip Prevents Stringing, Saving Molds & Cycle Time

New design is said to eliminate mold damage from nozzle stringing or work-arounds that slow cycles.

Read MoreHow to Prevent Nozzle Tip Leaks, Part 2

Your very costly mold in that very expensive press is relying on the performance of a $20 nozzle tip that no one ever checks, and has a high probability of not doing its job. Stop learning from your mistakes and start learning how not to make them.

Read More

.jpg;width=70;height=70;mode=crop)