Understanding Roll Deflection in Sheet Processing

Because of roll deflection, sheet stacks made for PS don’t work nearly as well with PP. One solution is to try a top roll that bends in the opposite direction.

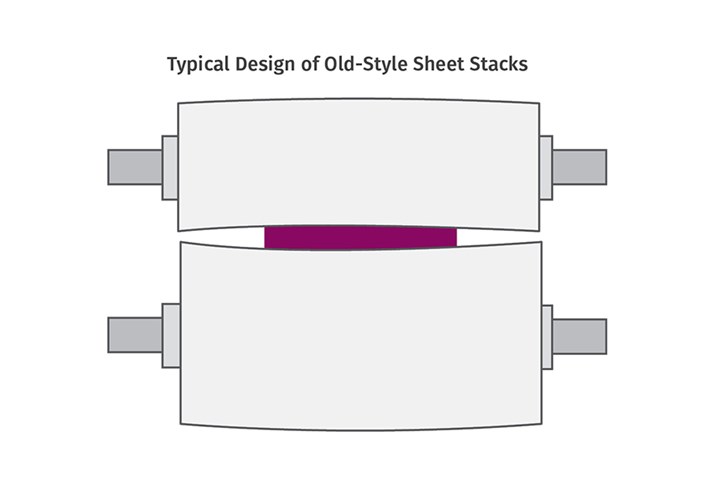

Many of the older sheet stacks still in use today were made for polystyrene or other easily deformed polymers. In these stacks, the top roll was usually smaller in diameter to facilitate an easier and safer “string-up” of the line (Fig.1). Since the polymer contact time with the top roll is only a few inches, the smaller roll causes almost no cooling.

But nowadays, with the conversion of many sheet products to polypropylene, this has resulted in many roll stacks having unacceptable roll deflection, resulting in sheet that is crowned. Polypropylene requires greater nip force to calender due to its viscoelastic properties as well as its tendency to increase in viscosity under certain levels of strain.

FIG 1 In old-style stacks designed for PS, the top roll was usually smaller in diameter to facilitate easier and safer “string-up” of the line.

Adding a larger-diameter top roll to an existing roll stack requires very extensive machine modifications; and if the middle roll is also deflecting, although to a lesser degree, the larger top roll only reduces—but not eliminates—the problem. An approximation of the separating force causing the deflection of rolls in a roll stack is shown in the following calculation:

Pounds of separating force in the nip per inch of length: PLI = G[3µ(2πN)R2]/4H

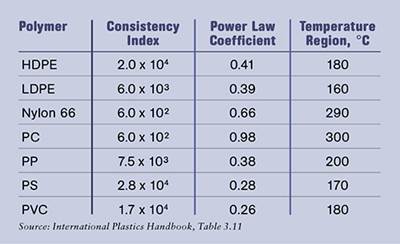

G depends on the size of the bank and the power-law coefficient, but for approximation you can use only the power-law coefficient, since the bank varies from day to day, as does its viscosity.

µ is the low-shear viscosity at the melt temperature.

N = rpm/sec

R is the roll radius

H is the roll gap

The PLI in the nip is thus proportional to the power-law coefficient of the polymer. The power law coefficient for PP is 0.38, while HIPS is 0.28. This means it takes 35% more force to hold the roll position with PP than HIPS. Notice that the separating force is divided by four times the nip height, meaning the deflection increases with declining sheet thickness.

So the issue with excessive deflection occurs predominantly with thinner PP sheet. With most thin sheet, the shear rates are typically low in the roll nip, so there is little shear thinning to consider except at very high line speeds. Roll radius is squared in the calculation, so its easy to see how roll diameter resolves the deflection issues.

The calculation illustrates how the variables contribute to the separating force. Taking the bank width times the separating force per inch equals the total separating force. That can then be factored into standard beam calculations to determine the roll deflection. The best way to determine the separating force is still to lower the closing pressure in the cylinders until the top roll “floats,” as that takes into account every variable.

Adding a larger-diameter top roll to an existing roll stack requires very extensive machine modifications.

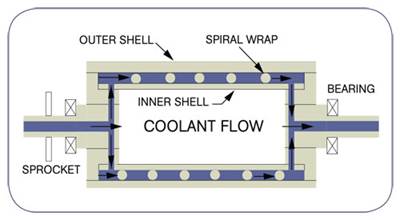

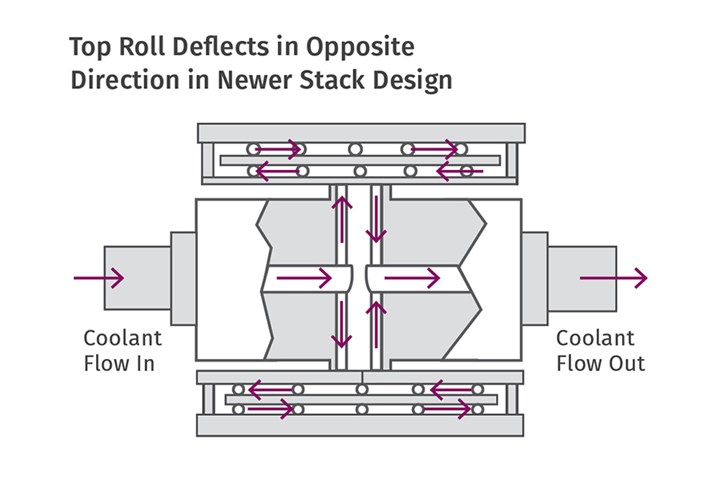

One possible solution is to use a top roll that deflects in the opposite direction. Even if both the top and middle are deflecting, the reverse-bending top roll can take that into account to maintain a parallel roll gap. A schematic of this design is shown in Fig. 2. There were many of these reverse-deflection rolls made for several years, which have been in continuous use since 1996; but New Castle Industries, the company holding the patent, went out of the roll business and few, if any, were made after 2004. The original patent expired in 2013.

FIG 2 In reverse-deflection rolls, the top roll deflects in the opposite direction. Even if both the top and middle are deflecting, the reverse-bending top roll can take that into account to maintain a parallel roll gap.

In the reverse-deflection roll design, a middle shell and center supporting the cooling surface off the center shaft is added so it deflects in the opposite direction. If the design of the opposing (middle) roll is known, its deflection can be exactly matched to the opposing roll by changing the thickness of the shells. The cooling can be designed for “in one end, out the other” or in/out the same end. By making the center shaft solid, almost all deflection of the shaft is eliminated.

I was reminded of the reverse-bending design when I was contacted by a sheet processor who has been using it for approximately 20 years and wanted some built for additional sheet lines. It may resolve your roll-deflection issues at much less expense than conversion of your existing sheet stack or purchase of a larger stack.

ABOUT THE AUTHOR: Jim Frankland is a mechanical engineer who has been involved in all types of extrusion processing for more than 50 years. He is now president of Frankland Plastics Consulting, LLC. Contact jim.frankland@comcast.net or (724)651-9196.

Related Content

The Role Barrel Temperatures Play in Melting

You need to understand the basics of how plastic melts in an extruder to properly set your process and troubleshoot any issues. Hint: it’s not about the barrel temperature settings.

Read MoreSingle vs. Twin-Screw Extruders: Why Mixing is Different

There have been many attempts to provide twin-screw-like mixing in singles, but except at very limited outputs none have been adequate. The odds of future success are long due to the inherent differences in the equipment types.

Read MoreTroubleshooting Screw and Barrel Wear in Extrusion

Extruder screws and barrels will wear over time. If you are seeing a reduction in specific rate and higher discharge temperatures, wear is the likely culprit.

Read MoreWhy Are There No 'Universal' Screws for All Polymers?

There’s a simple answer: Because all plastics are not the same.

Read MoreRead Next

Extrusion: Take Care of Your Rolls So They Can Play Their Role

In the sheet extrusion business, one of your most important manufacturing assets is your cooling rolls.

Read MoreThe Power-Law Coefficient

By referring to the power-law coefficient, the effect of barrel override in the metering section of many screws can be explained and anticipated.

Read MoreHow to Select the Right Cooling Stack for Sheet

First, remember there is no universal cooling-roll stack. And be sure to take into account the specific heat of the polymer you are processing.

Read More

.jpg;width=70;height=70;mode=crop)