Water Injection Beats Gas Assist in Lightweighting Car Door Panel

Renault’s conversion from metal-frame construction to plastics prototype switched from gas assist to water injection. Here’s why and how.

Recently, Renault in France introduced a lightweight-construction prototype automobile called Eolab. Among the objectives of the project was the investigation of materials and production methods that could be applied to exterior bodywork. The aim was to meet current and future requirements and regulations, while also saving vehicle weight and delivering new features and functions to the customer. Of course, increased use of thermoplastics was one of the solutions evaluated, and converting the side-door modules from metal-frame construction to plastics became one of the projects.

Using the technical specifications of the doors on Renault’s popular Megane Coupe, the challenge was to develop a replacement for the door’s central structural layer using 40% long-glass-filled polypropylene. In the end, the door-frame solution would meet several critical objectives:

• Design freedom, including functional integration of features without assembly or welding.

• Lower weight: The thermoplastic structure weighed almost 6 kg (13 lb) less than the steel design.

• Low total cost of production with an impressive 90-sec cycle.

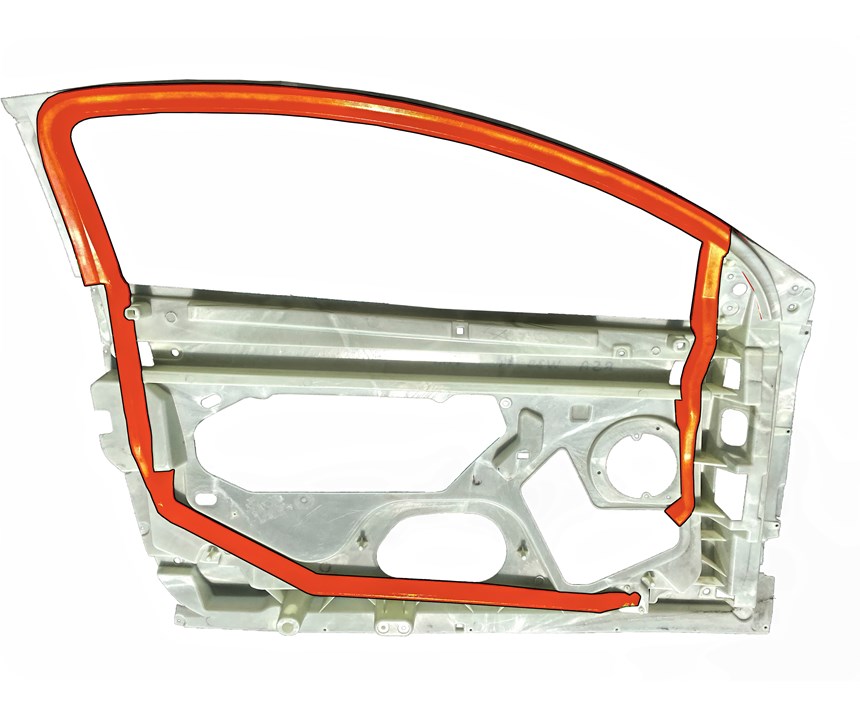

But getting to that result would not be easy. The engineers wanted to use many of the same door components—seals, windows, locking systems, handles—as in the original metal design. This meant that the glass-filled PP door would need stiffness and other mechanical properties similar to the metal structure. Designers decided to include a large-diameter channel around the outside of the door in order to meet these requirements. This channel would form the upper and side frame for the window and also connect the upper and low portions of the door.

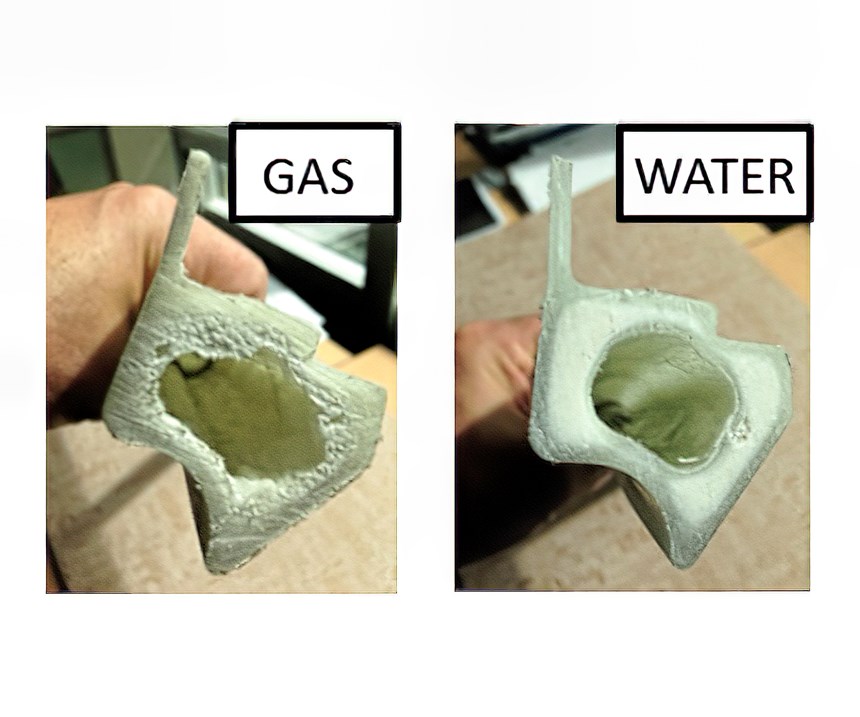

In order to keep weight to a minimum, Renault designers planned to use gas assist to hollow out this critical channel. However, the results of initial molding trials were disappointing, since both costs and cycle times exceeded project targets by a substantial margin. So they approached PME Fluidtec in Germany (pme-fluidtec.de/en), to see if water-injection technology (WIT) could achieve better results. PME Fluidtec specializes in supplying technology for both gas and water injection, as well as a Combined Injection Technology (CIT) that marries the two.

Water injection is more commonly accepted in Europe and Asia than in the U.S. today. It requires different mold-design features than gas injection for several reasons. First, gas injection uses an overflow chamber to receive the resin displaced by gas. PME Fluidtec, on the other hand, planned to use a technique that uses water to drive displaced material through hot-runner valves “back-to-barrel.”

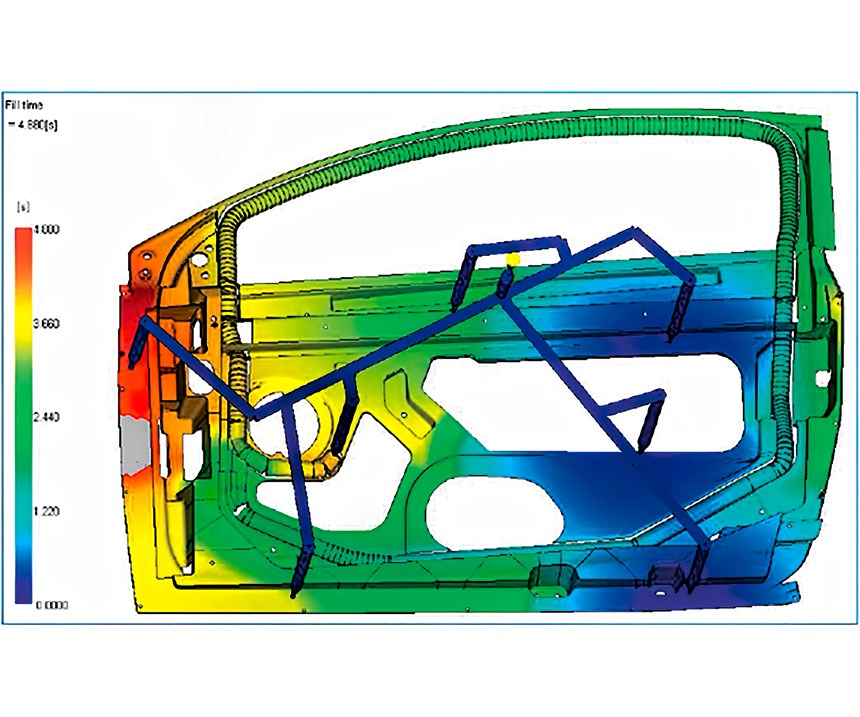

This decision necessitated redesigning the existing mold, with special attention to the hot-runner system. Hot-runner design normally would be straightforward for a typical injection molded part, but there were no established principles for a part that includes a large-diameter channel as a structural element. It was difficult to determine the number and location of the hot-runner nozzles and how the flow paths should be configured in a part with wall thicknesses that range from 2.7 mm in most of the part to 30 mm in the channel sections. That’s mainly because the pressure needed to fill the large-diameter sections is significantly less than is required to fill the thinner areas. This large pressure delta meant that, as melt flows into the channel during the injection phase, filling stops at all other gate points or does not start at all. Therefore the location of the gates and sequence of filling had to be carefully organized to achieve proper filling and avoid weld lines.

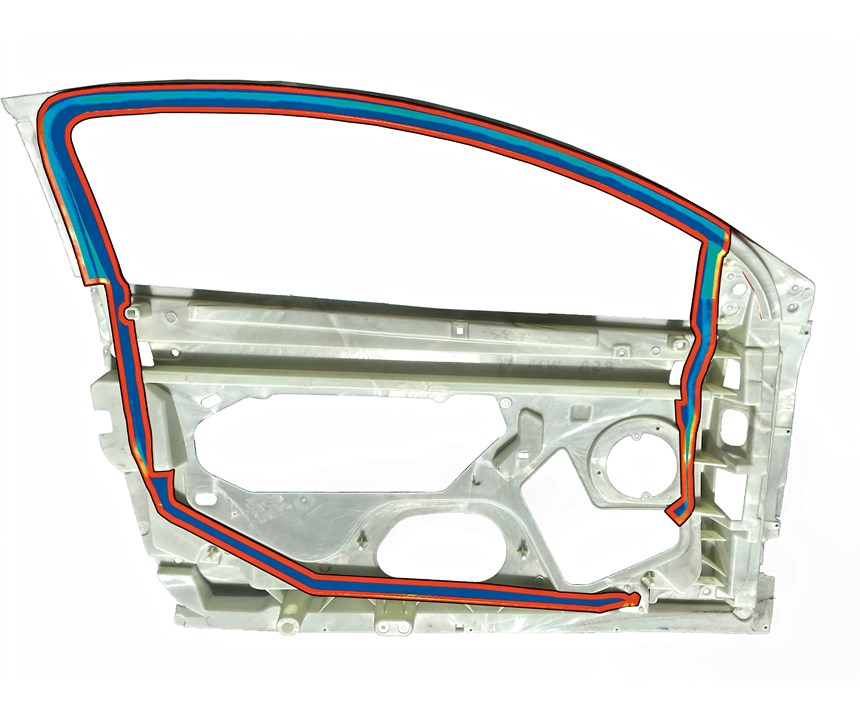

In addition the large-diameter structural channel itself had to be reconfigured slightly so that melt could flow in at one end and water at the other, pushing material back to the barrel at the injection site. Also, the water had to drain by gravity out of the channel after doing its work, so the water injector had to be located at a low point in the tool. In the end, the mold would be mounted in the machine at an angle (rather than square to the platens) to achieve the correct orientation for gravity draining.

Renault engineers conducted computer-aided mold filling studies with the original mold design, anticipating gas injection, but there was not much time to re-study the new tool design. Consequently, the automaker had to rely on the experience of PME Fluidtech technicians and a certain amount of trial and error to get the design right.

WATER OR GAS INJECTION?

One of the reasons that Renault decided to switch from gas assist to water was the greater flexibility and stability of water, which is due to its incompressibility. Thus, pressure and volume can be managed and controlled more effectively during the cycle, according to PME Fluidtec.

WIT also makes it possible for the channel to end at the place where it is required. The water pushes material back into the barrel until the hollowed-out area extends as far as it needs to and no farther. PME Fluidtec says the water volume and pressure can be controlled so precisely that the process is perfectly repeatable. The WIT system also controls the valve gates of the hot-runner system, as well as other mold or machine movements, so that all functions are perfectly synchronized.

Another advantage cited for WIT is the cooling effect of the water inside the channel. Water can cool the polymer 40 times better than gas, so the dimensional stability and resistance to deformation required for demolding are achieved very quickly. In fact, water injection reportedly can begin up to 10 sec earlier than with gas, without the risk of delamination or penetration of the fluid into adjacent thin-wall areas. Thus, cycle time reductions of 15 to 25 sec can be achieved without adversely affecting product quality, according to PME Fluidtec.

ENCOURAGING RESULTS

In the end, the result of the prototype door project exceeded expectations. Compared with the steel version, the plastic-framed door module reduced weight by 9 kg. The new door passed all essential validation checks and could be assembled now in production vehicles. Cycle time was around 90 sec, which was longer than the original target, but acceptable. Stiffness and other mechanical properties were about 5% better than predicted.

Automobile manufacturers like Renault and Nissan are already using plastics in components like tailgates. The Renault door project demonstrated that is practical to also use thermoplastics even for large components like doors and body panels. PME Fluidtec believes that similar results could be achieved in such components as front ends, car seats, backrests, battery cases and wheel wells. Water injection may prove important to realizing such solutions by creating cavities that result in higher component stiffness.

Related Content

How to Design Three-Plate Molds, Part 1

There are many things to consider, and paying attention to the details can help avoid machine downtime and higher maintenance costs, and keep the customer happy.

Read MoreGot Streaks or Black Specs? Here’s How to Find and Fix Them

Determining the source of streaking or contamination in your molded parts is a critical step in perfecting your purging procedures ultimately saving you time and money.

Read MoreBack to Basics on Mold Venting (Part 2: Shape, Dimensions, Details)

Here’s how to get the most out of your stationary mold vents.

Read MoreOptimizing Pack & Hold Times for Hot-Runner & Valve-Gated Molds

Using scientific procedures will help you put an end to all that time-consuming trial and error. Part 1 of 2.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More