What is Backpressure and How Should We Calculate It?

Does using an intensification ratio to calculate backpressure result in an accurate reflection of what’s happening in the barrel? Newer machine technologies have us revisiting an old project with fresh eyes.

Over the years I have had several, let’s call them, “discussions” with molding machine manufacturers regarding to machine setpoints and outputs. I even recall my first conversation arguing the merits of using air shots to clock actual injection-speed capabilities. I’ve never been one to keep my thoughts to myself, especially when I feel strongly enough about them, and I have some new thoughts about calculating backpressure.

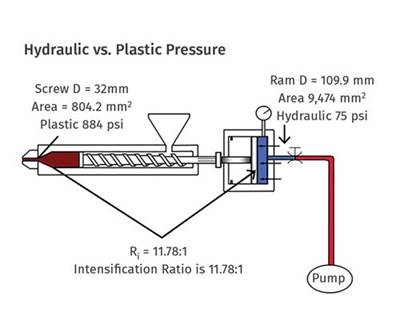

The genesis for this article actually came more than 10 years ago while I was working on a combination process/production monitoring project at a medical molder, which I wrote about in my February ’21 column (Process Monitoring or Production Monitoring—Why Not Both?).

Let me give you a little background. One of the objectives of that original project was to not just eliminate the need to document the CPOs (critical process outputs) manually twice a shift, but to make the process completely automatic and increase the frequency to 100% of the cycles, ensuring that no part was sent to a customer that wasn’t run within those CPOs.

This being medical molding, we couldn’t just network the machine controllers and only rely on their data. We needed a true third-party system to verify the outputs and gather the data. Thus the need for a monitoring system. The project included adding third-party pressure sensors, position sensors and even temperature sensors in order to have a true verification of the process outputs.

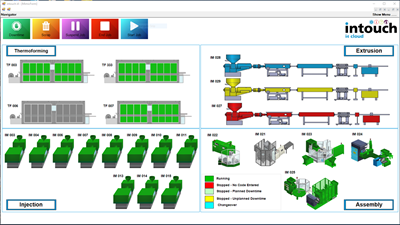

Understanding what’s actually happening with plastic pressure at the nozzle has a lot to do with the backpressure in a process. (Photo: Getty Images)

This was done to avoid any creative math by process techs in the background that could possibly impact the outputs on the machine’s controller. The team identified more than its fair share of that number fudging, which I have highlighted in previous articles.

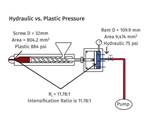

The pressure sensors that the team installed were typically placed near the machine manufacturer’s transducers. This was done to help ensure the outputs wouldn’t be different due to sensor location. This also meant that we did not install a transducer in the melt to measure the actual plastic pressure during injection. Instead we would use the intensification-ratio conversion from hydraulic pressure to plastic pressure.

This was all done in an effort to avoid significant deltas between the machine’s outputs and the monitoring system’s outputs that might arise from inconsistent measuring techniques. I should note that the processes were all qualified with our medical customers, using the machine’s outputs. Depending on the size of the delta, the differences could result in a burdensome requalification process. Don’t get me wrong, we did have to complete a few of these due to some of that creative math I mentioned, but those were the exceptions.

My question was and is: Why are we calculating backpressure into plastic pressure using the intensification ratio?

So, ultimately we ended up with well-equipped machines capable of providing data that most could not. That said, we still had no ability to measure actual plastic pressure at the nozzle, and that is why I haven’t written about backpressure as a main topic. I have mentioned my thoughts on backpressure, alluding to it in some previous articles, and I have had discussions with many machine manufacturers, including the one I worked for, but I never had the opportunity to follow up on this with a machine equipped with a functioning pressure transducer at the nozzle tip. That is , not until now.

Back to Backpressure

My big issue with how machine manufacturers calculate and display backpressure started several years ago during the project mentioned above. We had recently been awarded some new insert-molding business that required downsizing the screw and barrel on a vertical injection molding machine. This was no small downsizing either, as we took the barrel as low as it could go with this particular injection unit and machine. The machine itself had a maximum hydraulic injection pressure setting of 3300 psi, and once the new smaller screw and barrel were installed, this caused the intensification ratio to increase to 20:1, taking the maximum plastic pressure (PPSI) to 66,000.

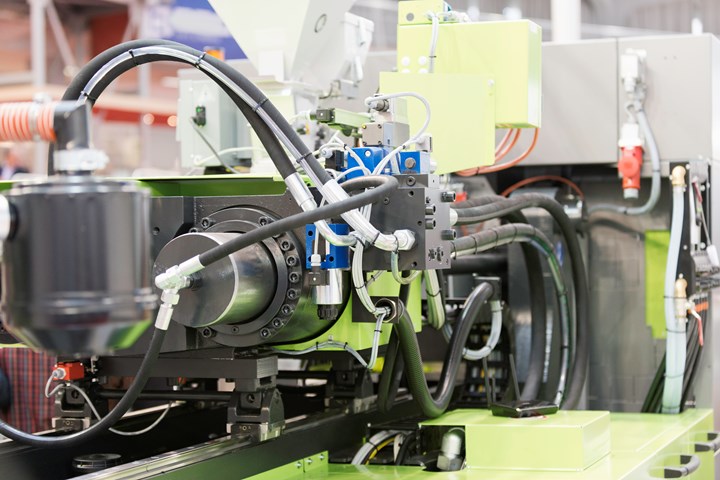

Understanding how your machine control calculates backpressure is key to better understanding your process. (Photo: Arburg)

We were all so focused on the maximum injection pressure—and rightfully so—that no one even considered the impact this reconfiguration could have on the backpressure. The machine manufacturer did program the machine to a maximum injection pressure of right around 30,000 PPSI—pressure limiting it with software to prevent blowing the mold apart. This protected our mold and machine from damage but didn’t help us to consistently produce a good part.

We were unable to find a stable process, regardless of the setpoints, molding short parts on one shot and then flashing on the next. Considering we had well-equipped machines, once the data was reviewed it wasn’t difficult to find the issue: Screw recovery time was all over the map.

If you ask 10 processors to define backpressure, I promise that you’ll get 10 different answers, and most of those answers will be what it does, not what it is.

So we started to increase the backpressure, which had a maximum setpoint of 1500 PPSI. The backpressure, along with all the other injection pressure settings or outputs, were converted using the machine’s intensification ratio. We did start to see an improvement in repeatability when we maxed out on this setting, but something just wasn’t adding up to me. So I did the math and to all of our surprise, 1500 PPSI of backpressure, with the new intensification ratio, was equivalent to setting the backpressure at 44 psi hydraulic. That’s when I really started asking: Why are these machine controllers designed to calculate backpressure in plastic pressure?

How Should We Calculate Backpressure?

Backpressure is the setting of how restrictive the proportional return valve will be as the hydraulic fluid returns to the hydraulic fluid tank during screw recovery. So we’re told the higher the backpressure setting, the smaller the opening will be and the lower the setting, but in reality, the opposite is true.

Among other things, backpressure determines how hydraulic fluid returns to the tank during screw recovery. (Photo: Getty Images)

My question was and is: Why are we calculating backpressure into plastic pressure using the intensification ratio? Remember, the intensification ratio is the ratio between the diameter of the hydraulic piston pushing the screw and the screw diameter itself. Backpressure is generated going in the opposite direction, created by the plastic itself as it pushes the screw back. The pressure of the plastic in front of the screw builds as the screw rotates and forces more plastic forward. Once that plastic generates enough pressure to exceed the pressure required to force hydraulic fluid through the proportional return valve, then the screw begins to retract its position.

This should result in a plastic pressure in front of the screw that is just north of the hydraulic pressure reading at that valve. So I’ll ask again: why are we using the intensification ratio on backpressure? I understand it might be easier to write a code for the machine’s HMI that is all or nothing, but if it is not a true and accurate reflection of the process, I don’t think easier controller programming is a good enough reason.

A New Insight

I recently visited with iMFLUX, a company that has spent a few years developing a pressure-controlled process in which it uses a specially designed nozzle equipped with a pressure transducer. This transducer allows the iMFLUX system to adjust fill speeds in real time to maintain a consistent injection pressure throughout the injection cycle. It also can read actual plastic pressure during screw recovery.

For the first time, I was able to see plastic pressure outputs during screw recovery that confirmed my concerns that using an intensification ratio (Ri) for backpressure is not an accurate reflection of backpressure. It is more accurate to leave it as a hydraulic setpoint than to multiply it by the Ri since there is no intensifying of the screw diameter moving backwards. This would have saved us many long days when dealing with that insert-molded product many years ago. I think backpressure is still sort of a dirty word to some processors, just like suckback or decompression.

If you ask 10 processors to define backpressure, I promise that you’ll get 10 different answers, and most of those answers will be what it does, like “adds heat to the material” or “can increase shot volume,” not what it is. I’ve asked some processors why they set their backpressure so low, and I’m told, “It causes too much heat—less heat in less heat out.” While there is some truth to that, you have to ask yourself, “How much cycle time could that extra heat really be adding compared with the benefits of a consistent screw-recovery time?” When you understand what it really is—resistance behind the screw during screw recovery—and what that does to prevent the screw from just zipping back uncontrollably, it isn’t hard to understand why it is critical to a robust and repeatable process.

Related Reading: How Backpressure Optimization Affects Melt Preparation

ABOUT THE AUTHOR: Robert Gattshall has more than 22 years’ experience in the injection molding industry and holds multiple certifications in Scientific Injection Molding and the tools of Lean Six Sigma. Gattshall has developed several “Best in Class” Poka Yoke systems with third-party production and process monitoring such as Intouch Monitoring Ltd. and RJG Inc. He has held multiple management and engineering positions throughout the industry in automotive, medical, electrical and packaging production. Gattshall is also a member of the Plastics Industry Association’s Public Policy Committee. In January 2018, he joined IPL Plastics as process engineering manager. Contact: (262) 909-5648; rgattshall@gmail.com.

Related Content

Why Shoulder Bolts Are Too Important to Ignore (Part 1)

These humble but essential fasteners used in injection molds are known by various names and used for a number of purposes.

Read MoreBack to Basics on Mold Venting (Part 1)

Here’s what you need to know to improve the quality of your parts and to protect your molds.

Read MoreInjection Molding: Focus on these Seven Areas to Set a Preventive Maintenance Schedule

Performing fundamental maintenance inspections frequently assures press longevity and process stability. Here’s a checklist to help you stay on top of seven key systems.

Read MoreWhere and How to Vent Injection Molds: Part 3

Questioning several “rules of thumb” about venting injection molds.

Read MoreRead Next

Understanding Intensification Ratio

A first step in taking the “art” out of molding.

Read MoreUnderstanding—and Using—Decompression to Your Advantage

Decompression—aka suckback—is a very important setting on an injection molding machine. On today’s machines, molders typically get the option to set decompression before and after screw rotation/recovery. Are they using this feature to their advantage?

Read MoreProcess Monitoring or Production Monitoring—Why Not Both?

Molders looking to both monitor an injection molding process effectively and manage production can definitely do both with tools available today, but the question is how best to tackle these twin challenges.

Read More