Regrind can be a tremendous asset, a costly liability, or just an afterthought taking up shelf space. For plastics processors who use or produce regrind, steps should be taken to track and manage it like any other material. However, this can require time and effort; and is not necessary in all cases. Here are a few questions to help you determine whether tracking regrind is right for your operation.

Does it Impact the Bottom Line?

For many processors regrind is a cost-saving recipe ingredient and added revenue source. In addition to saving expensive virgin resin, plastic processors may allocate the cost of regrind processing as part of product costing. They may also deduct the cost of what they receive back from the recycler. Others may simply charge the full cost of the virgin raw material and processing time to the job and recover regrind sold to the recycler as a bonus.

On the other hand … Thermoforming processors and companies dealing exclusively with virgin materials do not utilize regrind and obviously have no reason to track it.

How Complex is the Recipe?

Plastic processors relying on a single recipe or two may not place importance on regrind or its tracking. For many of these companies, scrap is simply a disposable byproduct.

Processors that use a variety of materials, recipes and colors in their process need to consider setting up a system to track scrap.

Processors that use a variety of materials, recipes and colors in their process need to consider setting up a system to track scrap.On the other hand … Complex recipes require material tracking. And more than one plastics processor has learned a lesson in regrind tracking the hard way. For example, color can be an important branding differentiator, where even the slightest variations in shade are unacceptable. And so, discovering a color discrepancy halfway through a run, the processor had no choice but to scrap the entire job. In this instance, the wrong regrind was added to the recipe.

The result of this error was lost production time, lost inventory, and lost money; and this company was fortunate that the customer was not lost as well. Improperly managing regrind can have serious consequences.

Is it Worth the Time and Trouble?

It’s generally assumed that material management requires a sophisticated solution; but that’s not always the case. Regrind tracking can be improved significantly by simply implementing a few basic steps. Here are some things to consider.

If you are using minimal variations of material, consider separating that material into bins or zones and labeling each with a corresponding colored placard. This will help avoid contamination and provide better value for those selling it.

Regrind tracking can be improved significantly by simply implementing a few basic steps.

Segregate regrind into three raw-material classifications: Green, Yellow and Red. Green indicates regrind of great quality, Yellow lower quality or what had been produced using Green regrind. Finally, Red is what is sold to recyclers and consists primarily of regrind produced from products using Yellow regrind or contaminated material.

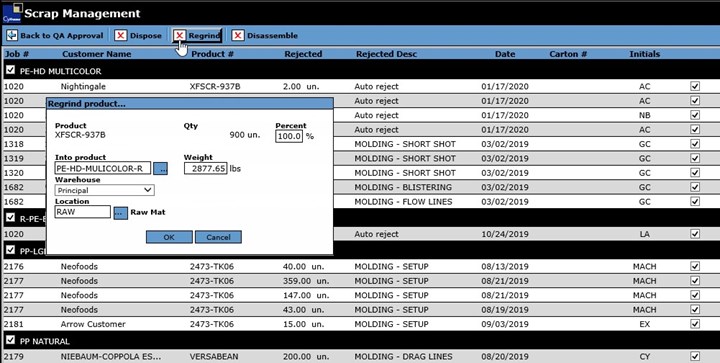

ERP systems can be an effective tool to manage scrap generated in-process. This one converts rejected finished products into regrind inventory.

Create three recipes for all products that could use regrind. One with 100% virgin resin, one with a percentage of Green regrind and one with a lower percentage of Yellow regrind. Next mark each Gaylord or container of regrind with a Green, Yellow or Red tag to avoid mistakes on the shop floor.

On the surface, some processors would seem to have no use for regrind or its tracking. But again, companies recycling or selling remnants/regrind can benefit from its proper management. It helps to have a process in place to organize, sort and store the material. Taking the time to separate scrap or regrind by color and/or quality adds value and helps secure the best price from buyers.

Here are a few more ways to improve regrind tracking:

• Declare all production rejects as they are generated.

• Group scrap by raw-material type and color.

• Separate reusable from contaminated scrap.

• Use a fixed percentage when estimating scrap. It is generally not worthwhile to try to specify the exact level for each product.

• Code regrind with a different SKU than virgin material, with a realistic unit cost.

• For each mold, have one recipe that uses virgin material and a second recipe that uses regrind.

On the other hand … As a plastics processor, you’ve got dozens of daily concerns. Will we win that big contract? Can we meet that tight delivery schedule? Should we add a third shift? Worry about the things that have a direct impact on your business. In many instances, regrind may not be one of them.

Do You Have the Right Tools?

To help manage regrind, some processors have turned to spreadsheets. While these basic applications can be overwhelmed as jobs get bigger and more complex, they are generally acceptable for most simple situations.

When your company begins to outgrow your tracking tools, consider the following steps:

-

Stop tracking regrind altogether.

-

Continue using spreadsheets and live with their shortfalls.

-

Employ a robust software solution.

On the other hand … Manually cataloguing regrind material is time-consuming, costly and inexact. While some can achieve proper regrind management by implementing a few basic manual steps, more complex situations require a more robust approach. Because of this, many simply do what they can and hope for the best. Consequently, any accumulated information is almost instantly out of date. Without access to real-time information, processors are never quite sure that they have the right amount and type of regrind in stock to run the job effectively and turn a profit.

If regrind tracking is important, and you utilize multiple recipes, then an ERP system is likely the best option. These systems serve as an information hub integrating production, inventory, sales, finance and other shop-floor and front-office applications. This provides detailed and current information about a specific customer or job and that customer’s unique requirements for the percentage of acceptable regrind that goes into the mix. For those selling regrind, ERP systems tell exactly how much of the scrap/remnants are reusable, along with the quantity and value of regrind on hand.

If regrind tracking is important, and you utilize multiple recipes, then an ERP system is likely the best option.

Do You Inventory Regrind?

Companies using 100% virgin resin, or those with simple recipes, have no real need to track regrind. Even those recycling or selling regrind as scrap can justify excluding the material from inventory.

On the other hand … For processors that employ regrind, inventory accuracy is critical. Consider a company whose books showed $100,000 in raw-material inventory. So why, with abundant resin in stock, was it constantly being reordered?

An inventory audit revealed that a large portion of material being recorded as resin was in fact regrind. Over time, the amount of regrind in stock steadily increased, eventually creating an inflated raw-material inventory value while hiding a substantial loss.

In this instance, $50,000 worth of regrind was unknowingly counted as virgin material. This error not only skewed financial reports provided to banks and investors; but the next day after discovering this error, the company was hit with an unexpected loss of $50,000. The bottom line is this: if you’re using regrind and not tracking it, hidden costs such as this will find you at some point.

Focus on What Matters

Depending on the processes you employ, tracking regrind may or may not be necessary. Step back and take an objective look at your operation and consider whether tracking regrind contributes toward your business goals and bottom line. Ask yourself, is regrind important; and if so, are we managing it effectively? If it’s not important, turn your attention to what is. But if you’re not giving regrind the attention it deserves, start doing so. Even small steps can make a big difference.

If you’re considering an ERP system, do your homework and ask the right questions. Remember, one size does not fit all. In addition to volume, the origin of the material must be determined, tracked, and made instantly accessible. Furthermore, virgin resins may include additives such as color, fillers, lubricants, stabilizers, and so on. These may require a secondary drying step that must also be accounted for. Not all ERP systems will have the complete functionality that our industry requires.

If you’re considering an ERP system, do your homework and ask the right questions. Remember, one size does not fit all.

It’s important to focus on what counts. If regrind is one of those things, select and implement a tracking strategy that’s right for your situation and commit to it.

About the Author: Manuel Riano is an industrial engineer for CyFrame International Enterprises in Montreal. He has nearly 14 years’ experience in the plastics industry. He has overseen the successful implementation of more than 40 process-improvement initiatives for plastic processors, with approximately 80% of those cases involving regrind management. A native of Columbia, Manuel is a practitioner of Six Sigma, Kaizen, Lean Manufacturing and 5S and has worked with manufacturers to implement quality-management systems under ISO 9001-2000 standards. Contact: (514) 693-0999 ext. 233;; mriano@cyframe.com; cyframe.com.

Related Content

Nova Chemicals Attains FDA Letter for Mechanically Recycled LLDPE

RLLDPE product will be marketed for applications including food packaging.

Read MoreMarket Changes Spur Industrial Recycler to Enhance Capabilities in Clear Plastic Reprocessing

Butler MacDonald found new business and flexibility thanks to a big step-up in purging efficiency.

Read MoreNew Facility Refreshes Post-Consumer PP by Washing Out Additives, Contaminants

PureCycle prepares to scale up its novel solvent recycling approach as new facility nears completion.

Read MoreEvolving Opportunities for Ambitious Plastics Recycler

St. Joseph Plastics grew from a simple grinding operation and now pursues growing markets in recycled PP, food-grade recycled materials, and customized post-industrial and post-consumer compounds.

Read MoreRead Next

Is Your Granulator Helping You Maximize Your Profit?

It’s easy to take a scrap granulator for granted. Many people do. But getting the most value out of your production scrap requires both a granulator design and a preventive-maintenance program that are appropriate to the way you use the granulator.

Read MoreAvoid Four Common Traps In Granulation

Today, more than ever, granulation is an important step in the total production process. Our expert explains a few of the many common traps to avoid when thinking about granulators

Read MoreHow the Right Granulator Helps You Get the Most Out of Your Material

Not all granulator designs are the same, so which one is right for your application? The one you have today may have been purchased for an entirely different application and may not be best suited to your needs. Here are some things to think about that can help you decide what’s best for you.

Read More