New Facility Refreshes Post-Consumer PP by Washing Out Additives, Contaminants

PureCycle prepares to scale up its novel solvent recycling approach as new facility nears completion.

A new kind of recycling facility is taking shape on the banks of the Ohio River. PureCycle’s Ironton, Ohio, site is nearing completion of a massive expansion that will create an industrial-scale facility for purifying post-consumer polypropylene.

Polypropylene is favored for many applications due to its high specific strength, resistance to heat and chemical degradation, and versatility. PP products can and are made in innumerable shapes and colors, formed from fibers, containers, films, and more. But this versatility becomes a challenge when recycling PP. Recycling of HDPE milk jugs, for example, is facilitated by the uniformity of the target. Material recovery facilities (MRFs) everywhere exploit the way HDPE natural containers reflect light, using optical scanning systems to sort them from mixed streams.

Gray pellets resulting from traditional recycling of mixed color PP. This material will be processed as feedstock by Purecycle.

Photo Credit: Matt Stonecash

With PP, recovery facilities are dealing with a much broader mix of formulations, colors, and morphologies. The result is a mixed-color flake that becomes a gray pellet. The gray pellets have value and can become new products, but that value is limited by the available applications. You cannot take those mixed flakes and turn them back into clear pellets that look like virgin material. Or can you?

Purecycle’s product: clear, pure PP ready for conversion.

Photo Credit: Matt Stonecash

New Solution to the PP Recycling Problem

Aiming for higher quality than is produced by mechanical recycling, and lower environmental footprint than from existing chemical recycling processes, consumer-goods giant Procter & Gamble developed and patented a solvent-wash recycling process for PP. In 2015, PureCycle Technologies was created to scale up the technology and was licensed to commercialize the process.

The new plant is on the site of a former Dow facility that produced polystyrene. Lawrence County Development Corp. had purchased the property, hoping to find a use that would help the area recover employment and economic activity. They found PureCycle, and in 2019 the pilot plant began processing carpet into recycled PP.

“It’s a good area,” says Dustin Olson, CEO at PureCycle. “You want to be close to people and close to industry, because that’s where you get post-consumer and post-industrial waste. “

Construction is nearing completion of the scaled-up, modified version of the pilot plant at the same site. It is expected to be finished in April, and will have a capacity of around 100 million lb/yr.

Cleaning Plastic at the Molecular Level

Diverted waste material will start in the prep facility, where PureCycle has a variety of familiar equipment for preparing the various manifestations of PP products. There are agglomerators for densifying film and fibers, a grinder for breaking down rigids, and a washing line for removing external contaminants.

Prepped materials feed into one of a pair of KraussMaffei extruders that in turn deliver melted plastic to the heart of the plant, the solvent purification system. Over 100 ft high, the purification system is crisscrossed with a complex network of piping. But each component has its purpose.

“Think of it as a molecular washing machine,” says Olson. “At a mechanical recycling facility, they wash the outside of the plastic. I will wash through it.”

PureCycle’s purification system for PP. Modules were fabricated in Texas and shipped upriver for assembly at Ironton, Ohio. (Photo: Matt Stonecash)

In the extraction column, melted PP is introduced to a solvent under critical conditions. Under these conditions, organic, non-PP materials such as processing additives are separated from the PP. A settling stage then removes inorganic materials; and finally the material is filtered, leaving pure polypropylene. The company refers to its PP pellets as a “no-compromise” drop-in replacement for virgin, fossil fuel-based PP. The solvent is reusable, so it is recovered and routed back through the process.

Process Efficiency and a Sustainability Edge

PureCycle has used its pilot plant to refine its process for efficiency. Lifecycle analysis indicates the solvent-based recycling process provides 35% smaller carbon footprint than virgin, fossil-based PP production. There is reason to think this number will likely increase in the future, as the process is far more energy efficient than virgin PP production, using 79% less energy per pound of product.

Ironton is part of the Huntington-Ashland metropolitan area, where Ohio meets Kentucky and West Virginia, and where energy comes mostly from coal. Reports from the Intergovernmental Panel on Climate Change (IPCC) have identified coal combustion as the energy supply with the largest lifecycle greenhouse gas emissions. Any change in energy mix will therefore allow PureCycle to reduce its carbon footprint even further. One strategy the company is exploring is rooftop installation of solar panels on some of the site’s buildings.

In Augusta, Ga., the planned location of Purecycle’s next facility, the energy mix is already very different, thanks to a nearby nuclear power plant. “We’ll have a much lighter carbon footprint there than we will here,” says Olson. Water usage is also expected to be reduced through the company’s investment in a more efficient water-treatment system from Krones.

Building a New Operation Amid Tumultuous Times

When construction on the new plant began, the COVID-19 pandemic had already hit. The global semiconductor shortage, the war in Ukraine, and the COVID surge that hit Germany last fall have all impacted the delivery of necessary equipment. Plans for opening in 2022 had to be delayed.

“The world is tough right now for the supply chain”, says Olson. “When we build in Augusta, it will be a much smoother process.”

Despite disruptions caused by war, a pandemic, and all the associated logistical problems, the site is now a flurry of activity as construction nears completion.

Dustin Olson, CEO at PureCycle, with recovered yard signs promoting candidates of all stripes. The signs are of PP and will be turned into like-new pellets. (Photo: Matt Stonecash)

Recycled PP carpet, containers, film, even political campaign signs, are on-site and ready to be processed. Soon, renewed PP pellets will start rolling out of Ironton. PureCycle is confident that when they do, customers will be pleased with what they see.

“We’re the only ones in the world that can make a product like this. No matter what happens with prices in the short term, people are going to want it,” says Olson. “If they have a goal to reduce fossil PP usage, and they have a product that demands higher quality than mechanical recycling, they should be calling us.“

PureCycle plans to open the Augusta facility in the second half of 2024 with initial capacity of at least 260 million lb/yr. The company will expand its operations into Asia and Europe in the future with planned plants in Ulsan, South Korea, and Antwerp, Belgium.

Related Content

The Importance of Mass Balance in Chemical Recycling

Approaches to mass balance can dramatically impact calculations of recycled content.

Read More‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MoreMultilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

Read MoreProcessing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

Read MoreRead Next

Making Polypropylene the Next Big Thing in Recycling

PureCycle Technologies’ solvent-based recycling process returns polypropylene to a pristine state.

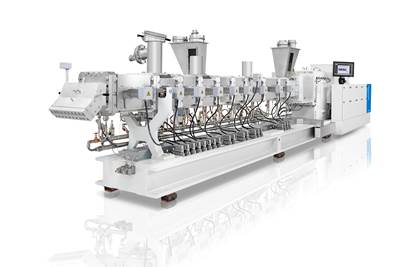

Read MoreSolvent-Based Recycling: Emerging Technology for Reclaiming & Purifying Polyolefins with Twin-Screw Extruders

Just now being applied commercially, solvent-based recycling turns colored polyolefin waste into clear, clean and even food-grade resin comparable to virgin—all while keeping the polymer structure intact. Specially engineered systems of tandem twin-screw or twin- and single-screw extruders can do the trick.

Read MorePureCycle to Supply Recycled PP to Berry

The material will be supplied to Berry in summer 2023 for manufacturing at one of Berry’s ISCC PLUS certified facilities.

Read More