100% Cellulose Film Resin Adopted by Restaurant Chain for Take-Out Packaging

Woodly and film converter Amerplast have applied the novel material to commercialization of heat-sealed sandwich bags.

We often report on emerging developments in bioplastics for which commercial applications are being sought through industry partnerships. Recently, we were approached by Woodly Oy, a Finnish company that has been developing a wood cellulose-based plastic for film packaging and other uses. Through a collaboration with Finland-based Amerplast, one of Europe’s largest flexo printers and bag converters of high-performance packaging for fast-moving consumer goods for both food and non-food categories, the company brought its novel material to commercial fruition.

The new, commercial application made from the 100% carbon-neutral and recyclable Woodly material film resin is a heat-sealed bag for takeout products launched by St1’s HelmiSimpukka restaurant chain in Finland.

Woodly CCO Tomi Nyman confirmed that the film is made 100% of Woodly, whose key raw material is cellulose and is also the main polymer backbone in the film structure. Woodly is reportedly suitable for film-blowing and cast film extrusion, among many other converting techniques, including injection molding. In the film packaging arena, while Woodly is primarily intended for monolayer films, it can be laminated with other polymers as well, according to Nyman.

More specifically, the Woodly film is an alternative solution to traditional cellophane with a reduced carbon footprint and improved recyclability. The film has been shown to also prevent moisture condensation and preserve the quality of fresh food products for longer. In addition to food packaging, the Woodly film can be used for labels and to wrap flowers and presents, just to mention a few example applications.

“We have a resourceful collaboration with Amerplast. With Woodly material we can cover many interesting packaging product categories that can benefit from the quality and characteristics of our material. As a producer Amerplast plays a key role when we are developing new material applications for the growing plastic film markets,” says Woodly CEO Jaakko Kaminen. His company sees a lot of new opportunities here to expand similar Woodly heat-sealed takeout bag solutions to other product categories as well.

Founded in 1952, Amerplast has extensive experience in plastics and the manufacturing of packaging. Amerplast provides packaging solutions for both food and non-food applications to the biggest brands in key market segments in Europe. With its AmerGreen program, Amerplast is taking a leading position in transforming the industry into an environmentally sound business. Amerplast is the market leader in carrier bags in Finland and the company’s bag solutions are based on the use of recycled materials in line with the circular economy model

Says Ari-Pekka Pietilä, Amerplast’s chief sales and marketing officer, “The wood-based plastic material offered by Woodly and our technical know-how is a perfect match that supports our commitment further to increase the use of biobased raw materials in the packaging we manufacture. We have strong expertise in food industry requirements and packaging materials. We are excited to collaborate with Woodly in investigating the potential of having an alternative to cellophane-type of material that fulfils our customers’ expectations. Our company’s strategic goal is to further increase the use of biobased raw materials in the packaging we manufacture.”

Since early Spring, St1’s HelmiSimpukka restaurant chain has been packing their display case sandwiches in the new heat-sealed takeout bag that made from the unique Woodly material. Recognized as one of the biggest companies in Finland, St1 and their HelmiSimpukka outlets are known for comprehensive services and delicious foods. With the new environmentally friendly packaging solution, St1 aims to reduce food waste, increase consumer recycling and also to improve the quality and shelf life of products.

“It is important for us to continuously develop our services and products. We offer our customers bread products made from high-quality ingredients. Sandwiches packaged in the Woodly heat-sealed takeout bags retain freshness even longer than those packaged in a traditional plastic bag, which supports our goal of reducing food waste. In addition, the Woodly heat-sealed bag is made of renewable material and is suitable for recycling, which is in line with our responsibility thinking,” says marketing & concept manager Emil Huttunen of the HelmiSimpukka chain.

Related Content

Honda Now Exploring UBQ’s Biobased Material Made from Unsorted Household Waste

UBQ is aiming to expand its reach for more sustainable automotive parts as well as non-automotive applications.

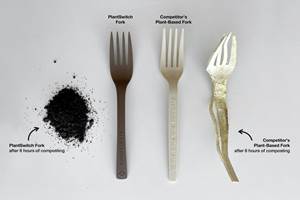

Read MoreAdvanced Biobased Materials Company PlantSwitch Gets Support for Commercialization

With participation from venture investment firm NexPoint Capital, PlantSwitch closes it $8M bridge financing round.

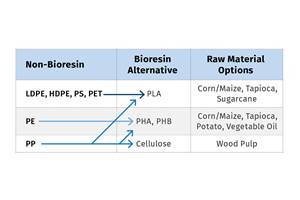

Read MoreHow to Optimize Your Molds and Hot Runners for Processing Bioresins

Demand for bioresins is growing in molded goods, particularly as a sustainability play to replace fossil-fuel based materials, but these materials are not a drop-in replacement for traditional materials. Molds and hot runners need to be optimized for these materials.

Read MoreBASF Highlighting How They 'Make, Use and Recycle Future Solutions'

NPE2024: BASF is using its proprietary computer-aided engineering tool Ultrasim when designing for sustainability in a broad range of industries.

Read MoreRead Next

People 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More