Borealis Starts ADCA-Free Foamed HDPE for Communication Cable

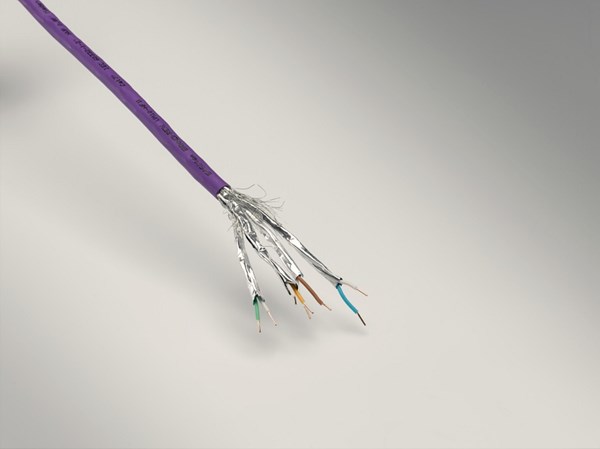

The development is said to be the first of its kind, and it meets Cat 6, Cat 7 and Cat 8 standards for physically foamed data cables.

Borealis AG (U.S. office in Port Murray, N.J.) recently unveiled what is believed to the first HDPE for foamed communication cable that is free of azodicarbonamide (ADCA) blowing agent.

Commonly used as a blowing agent for foamed communication cables, ADCA has been classified as a “substance of very high concern” by the European Chemical Agency (ECHA) due to its respiratory sensitizing properties.

Because the substance has now been recommended for inclusion on the ECHA Annex XIV list of compounds requiring prior authorization for use, a viable replacement fulfilling the same stringent quality and processing demands as ADCA has emerged.

Developed in partnership with Scotland-based Brand-Rex Ltd., a leading developer of cabling solutions for network infrastructure and industrial applications, Borealis’ HE4873 is a fully formulated HDPE compound containing a blowing agent for physical foamed data cable insulation. Borealis expects it to become the material of choice for next-generation, higher category communication cables.

The company cites the 2016 Cisco Global Cloud Index which has forecast a tripling of global data center IP traffic within the 2015-2020 time frame, with an overall compound annual growth rate of 27%. Factors contributing to rising data volumes include growth in the number of hyperscale data centers, and the increasing popularity of cloud computing. By moving towards higher category data cables, global communication networks can better respond to these trends.

Borealis’ HE4883 is both ADCA-free and meets requirements for categories Cat 6, Cat 7 and Cat 8 physically foamed data cables. It boasts the same benefits as its predecessor HE4873—long the leading foamed data grade for Cat 7 data cables used in data centers—but offers several advantages:

- Fully formulated compound for reliable consistency

- Optimal cell structure, for increased resilience, enabling higher twisting speeds and jacketing line speed without crush damage to cables

- Enhanced process stability with reduced preparation time, longer production runs, and less scrap

- Improved dissipation factor versus HE4873

- Higher lines speeds of up to nearly 2000 meters/min possible

- Improved dissipation factor versus HE4873

- Formulated to achieve best electric performance across a broad spectrum of frequencies

Said Kennedy Miller, technology and sustainability manager at Brand-Rex, “Using HE4883 in our products will allow the next generation of high performance data communication cables to use more environmentally sound materials whilst still maintaining the excellent processing capacity and electrical performance that we expect today.”

Related Content

-

How to Select the Right Cooling Stack for Sheet

First, remember there is no universal cooling-roll stack. And be sure to take into account the specific heat of the polymer you are processing.

-

Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

-

The Importance of Barrel Heat and Melt Temperature

Barrel temperature may impact melting in the case of very small extruders running very slowly. Otherwise, melting is mainly the result of shear heating of the polymer.