Ferromagnetic Nanoparticles Lead Quest for Reversible Adhesives

Promising research on reversible multi-material adhesive bonds could prove game changing in auto industry.

A key trend in automotive is the use of multi-material structures and, in turn, the ability to structurally join dissimilar materials and keep them together during the vehicle’s useful life, yet the need to separate them for repair, rejoin them and then separate them again at end-of-life for recycling has become increasingly important. This is particularly key for primary vehicle structures, which are far more safety critical than interior or exterior panels and, as such, vital to prevent unwanted separation during vehicle operation. They are also costlier to replace, which makes them highly desirable targets for repair rather than the junkyard if damaged.

Each of the conventional structural joining technologies—welding, mechanical fastening and adhesive bonding—fall short of ideal in this new multi-material reality, according to Peggy Malnati in a contributed article to the January 2018 issue of our sister publication Composites World.

Malnati reports on a multi-year research program involving the American Chemistry Council’s Plastics Division (ACC-PD) and Michigan State University (MSU) through its Composite Vehicle Research Center (CVRC; East Lansing, Mich.), headed by Lawrence Drzal, university distinguished professor and a renowned expert on composites, nanocomposites, and surface chemistry. This continuing effort has yielded surprisingly effective results in its quest to develop reversible adhesive joints that can be debonded and rebonded multiple times. Center stage in making this possible are ferromagnetic nanoparticles in thermoplastic adhesives, using electromagnetic energy,

According to the researchers, this capability could facilitate composites use in mixed-material vehicle structures because it gives adhesively bonded joints the durability and the reversibility of mechanically fastened joints, with reduced weight. Here’s s quick summary of how things have shaped up to date:

The team has used iron oxide nanoparticles at loading of 4-20% in a variety of thermoplastic adhesives. “We characterized the particles in and out of the adhesive, so we could understand their synergy and be able to predict when impact and strength would drop and what concentration was best so mechanicals stayed good but the bond was quickly reversible,” explained Mahmood Haq, assistant professor at MSU’s Department of Civil & Environmental Engineering. “For example, at 4% loading, the joint has good impact and strength, but takes 10 minutes to heat. However, at 12-16% loadings, we have a small drop in mechanicals but we can heat the joint in less than 20 seconds. Those bonds still carry loads, prevent fractures, resist fatigue and eliminate corrosion.”

The team started with nylons 6 and 66 followed by ABS, PC, HIPS and several olefin-based hot-melt adhesives. Thanks to professor Drzal’s surface-chemistry expertise and the team’s hard work, they now know how to adjust the surface chemistry of not only the polymers but also the nanoparticles and, as such, can make the technology work in just about any thermoplastic adhesive system. The technology is said to be fairly tailorable—amorphous, crystalline, polar or non-polar resins are usable—all being a matter of identifying application requirements, followed by adjusting the chemistry so functional groups on particles match up with those on the polymer, according to Haq.

Mike Day, ACC-PD technical consultant and career retiree from DuPont, noted that the team’s approach has been this that this is an ‘enabling” technology’. “We took a fairly broad view of thermoplastics as an adhesive element and tried lots of resins so we weren’t limited to one polymer family. This is pre-competitive work, so we knew we couldn’t figure everything out, but had to focus on proving the concept.”

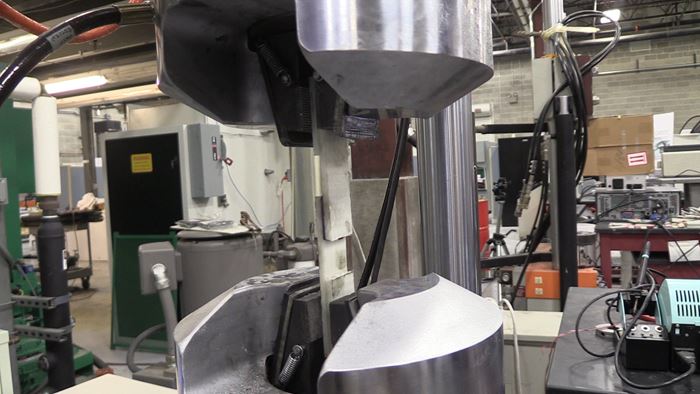

When resin/particle surface compatibility and substrate surface prep are correctly done, the team has achieved joint shear strengths in the range of 12-13 MPa (1741-1886 psi), which is said to be better than epoxy structural adhesives.

Interestingly, bond strength reportedly increases after several cycles of bonding/debonding vs. that achieved via convection heating alone. While the initial target was to create a reversible joint that could survive six cycles of bonding/debonding—a goal thought by the team as a reasonable lifetime expectation—they were pleasantly surprised to find joints surviving 20 and even 100 cycles. Also, electromagnetic bonding is faster than with convection ovens; it does not heat surrounding substrates and is amenable to automation.

Related Content

Additive Fusion Technology Optimizes Composite Structures for Demanding Applications

9T Labs continues to enhance the efficiency of its technology, which produces composite parts with intentionally oriented fibers.

Read MoreABC Technologies to Acquire Windsor Mold Group Technologies

The Tier One automotive supplier with compounding and blowmolding machine capabilities adds the 50-yr-old molder and moldmaker.

Read MoreImpacts of Auto’s Switch to Sustainability

Of all the trends you can see at NPE2024, this one is BIG. Not only is the auto industry transitioning to electrification but there are concerted efforts to modify the materials used, especially polymers, for interior applications.

Read MorePlastic Compounding Market to Outpace Metal & Alloy Market Growth

Study shows the plastic compounding process is being used to boost electrical properties and UV resistance while custom compounding is increasingly being used to achieve high-performance in plastic-based goods.

Read MoreRead Next

For PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreBeyond Prototypes: 8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples to look for at NPE2024.

Read More