Finnish Startup Gets IMSE Lighting Patent

TactoTek’s newly-patented technology available for licensing.

TactoTek’s newly-patented technology available for licensing.

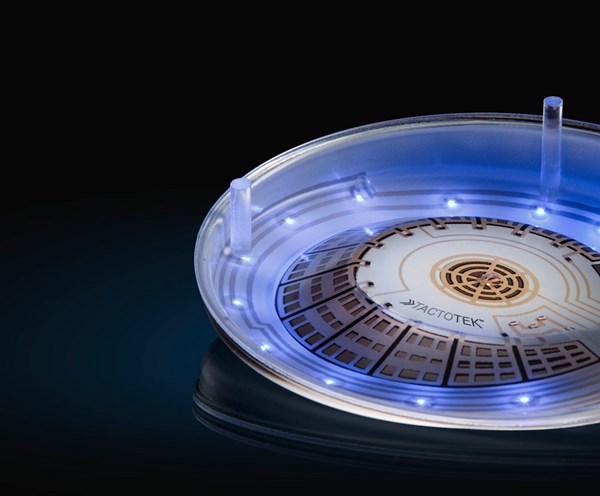

An interesting technology from a Finnish startup that has a unique method for integrating printed electronics such as circuitry, touch controls and antennas, as well as discrete electronic components such as LEDs, into injection molded plastics has been issued a U.S. patent (9297675). Applications for the so-called “illuminated indicator structures for electronic devices” include automotive, home appliances, wearables and health care.

The new technology from TactoTek, based in Oulu, Finland (U.S. office in Cupertino, Calif.) reportedly enables sophisticated lighting in very thin 3D plastic ‘smart surfaces’. “This patent recognizes a key innovation for injection molded structural electronics (IMSE) technology—employing the plastic material that is the structure of a part as a light guide. Using this technique, we can create very bright, evenly distributed illumination within structures as thin as 2-millimeters (0.079 in.),” according to CTO and co-founder Antti Keranen.

For illumination, TactoTek’s IMSE technology consolidates printed electronics and LEDs within the 3D molded plastic part and uses the plastics themselves to conduct light. This, in contrast with traditional electronics designs, which typically include a cosmetic surface structure and use a separate light pipe structure to direct lighting to the surface from a flat, rigid printed circuit board (PCB).

TactoTek’s approach of using the molded cosmetic surface as a light guide removes design constraints that had previously prescribed thick, multi-part assemblies, explains head of product management Hasse Sinivaara. “As we remove parts, we remove design time, weight and minimize electrical and mechanical assembly—very appealing when considering form factor innovation and total cost of ownership.”

TactoTek’s patented and patent-pending technologies integrate a mixture of well-known production technologies into a unique approach that enables mass production of 3D structural electronics. These include flexible circuit printing, surface-mounting electronic components, thermoforming, in-mold labeling (IML), and injection molding.

The approach starts with an IML material. Decoration, if desired, is printed, followed by conductive circuitry, and in some designs, printed touch controls and printed antennas. Electronic components are mounted using standard high-speed pick-and-place machinery. Electronics can be as simple as LEDs or as complex as microprocessors and are affixed to the IML using specialized adhesives able to withstand the temperature and pressure of injection molding. With electronics in place, the IML carrier is used as an insert for injection molding.

According to senior v.p. of marketing Dave Rice, the company uses a range of plastics that are standard for high-pressure, high-temperature injection molding, including: PC, ABS, and acrylic for rigid structures; TPU and hybrids, e.g., TPU/silicone for flexible structures.

Here is Rice’s answer when I asked if the company plans to license its newly-patented technology: “Our core business model is to help customers adapt their traditional electronics designs to TaktoTek IMSE technology and, develop mass production ready prototypes. For mass production, in some cases, we will manufacture parts ourselves; in most cases, we will license our technology and train a third party—typically an established Tier 1 supplier, to mass produce those parts.”

Related Content

‘Monomaterial’ Trend in Packaging and Beyond Will Only Thrive

In terms of sustainability measures, monomaterial structures are already making good headway and will evolve even further.

Read MoreMedical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read MoreUS Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

Read MoreMultilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read More