'First' PBTs for Extrusion of Profiles and Thermoforming

BASF will showcase the new Ultradur PBT portfolio extensions at K 2019.

We have devoted a significant portion of the September issue of Plastics Technology to what themes, equipment and materials innovations you can expect to see at K 2019 this October in Düsseldorf, Germany. In my K 2019 preview of resins and additives, I included news from BASF, which along with several other new materials and additives, will be highlighting its newly extended Ultradur PBT portfolio to include what is said to be the ‘first’ performance PBT extrusion grades for profiles and thermoforming.

Like BASF, other suppliers also opted to give us more or less a glimpse of what will be showcased at the show. Naturally, my colleagues and I are pouncing on some of the more interesting news to see if we can flesh out the technologies of interest. So here’s a bit more on BASF’s Ultradur PBT for extrusion, based on further clarification offered by the company after our initial reporting.

▪ Up until now, according to the company, the melt strength of PBT was simply not sufficient to make it a preferred product for extrusion. BASF scientists discovered that by connecting and branching the polymer chains via tailor-made additives, they were able to obtain a very high melt strength.

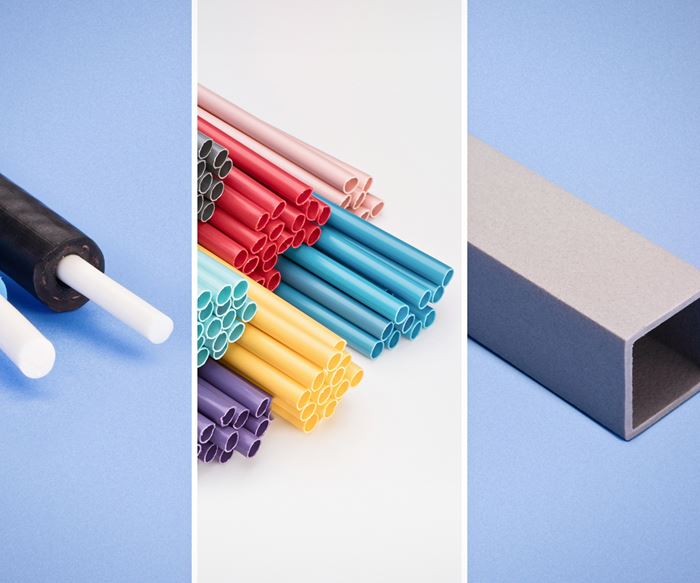

▪ This reportedly makes new grade B6551 LNI the perfect material for pipes, profiles and mandrels. In turn, new grade B6560 M2 FC TF is poised as the material of choice for extrusion of films and thermoforming of packaging or technical parts. Both grades reportedly offer good mechanical properties, are easy to color, and foaming is possible. Both also boast to combine all the well-known characteristics of the Ultradur family like high melting point, low water uptake, high dimensional stability and good barrier properties.

▪ Neither grade requires extrusion equipment changes. But, the company notes that drying is necessary, as is the case for PET.

▪ These grades are designed to replace the following: In the case of extruded profile, B6551 LNI can replace PET, nylons or metal and can be blended with existing reinforced Ultradur PBT grades depending on the applications; and, in the case of thermoformed packaging, depending on the requirements where heat stability and barrier properties are obligatory, B6560 M2 FC TF can replace PET, PP multilayer structures, ABS, or aluminum.

▪ According to the company, all products—profiles, tubes, mandrels, sheet and thermoformed packaging—have been successfully produced. Successful field trials have included: film extrusion at Infiana Germany GmbH & Co. KG.; thermoforming at ILLIG Maschinenbau GmbH & Co. KG; and, rod stock extrusion at Gehr. Stay tuned for more in future coverage!

Related Content

-

How to Select the Right Tooling for Pipe Extrusion

In pipe extrusion, selecting or building a complementary set of tooling often poses challenges due to a range of qualitative factors. Here’s some guidance to help you out.

-

Making Gains in the Drain Game

AWD blends extrusion and thermoforming technologies with plenty of home-brewed equipment and processes to keep water away from where it isn’t supposed to be.

-

KraussMaffei Adds to Pipe, Profile Sales Team

Fowler to handle sales for Southeast.