Here's Another Process for Foam Blow Molding

After two years of behind-the-scenes development, a new process for lightweight bottles emerges into the open.

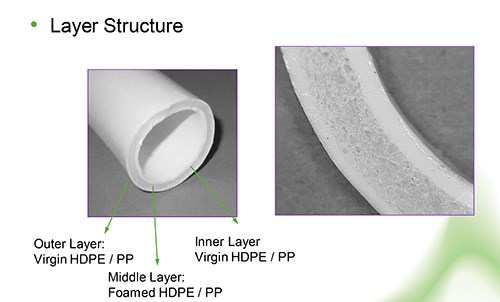

If anyone has a doubt that foam blow molding is on the verge of a renaissance, take a look at what W. Müller USA is doing. At NPE2015, the Agawam, Mass., maker of blow molding extrusion heads, spoke quietly with potential customers about a foam blow molding process that it has been working on behind the scenes since 2013. Company president Wolfgang Meyer gave Plastics Technology details on the process, which uses a special head design for three-layer coextrusion with solid inner and outer skins and a foamed center. What’s different about this process is that it uses nitrogen gas injection into the head, not into the extruder like other processes. It uses no chemical blowing agent—only talc as a nucleating agent, so it is acceptable for food packaging, Meyer says. For more details, see this month’s Starting Up section.

Other firms exploring foam blow molding include MuCell Extrusion, Trexel, and Plastic Technologies Inc.

Related Content

-

For Extrusion and Injection-Blow Molders, Numerous Upgrades in Machines and Services

Uniloy is revising its machinery lines across the board and strengthening after-sales services in tooling maintenance, spare parts and tech service.

-

How Inline Vision Inspection Can Minimize Scrap in Molding

Once viewed by injection and blow molders as a necessary evil, machine vision technology today can continuously monitor and improve production while reducing costs.

-

Get Color Changes Right In Extrusion Blow Molding

Follow these best practices to minimize loss of time, material and labor during color changes in molding containers from bottles to jerrycans. The authors explore what this means for each step of the process, from raw-material infeed to handling and reprocessing tails and trim.