Machine vision technology is widely used in the plastic packaging industry and throughout manufacturing processes in all markets that have any level of automation. Historical use of the technology was simply to reject defects from the production line, so that nonconforming output does not ship to the customer and lead to return costs.

In this mode of operation, vision systems were often considered to be a “necessary evil,” since they do not add to the production process, but rather reduce output by rejecting not only bad products but some that are borderline or, at times, even good products through false rejects. In the hands of an inexperienced operator, a natural tendency when a vision system starts to reject a large amount of product is to turn it off so that product can be shipped.

But that was the past. With proper design and application of industry-specific expertise, today’s vision systems can be used to continuously monitor and improve production and, ultimately, to reduce costs.

What Causes Scrap?

What are the causes of scrap in plastic product manufacturing? Scrap can be created by material variations, process settings, machinery malfunction, environmental conditions and operator error.

Material variations are only increasing with demands for sustainability and greater use of recycled materials. Material variations occur from batch to batch, and even within a batch. Two major areas where vision technology can help is inspection for color variations (yellowing, graying) and for presence of contamination (black specks).

Vision systems were often considered to be a “necessary evil,” since they do not add to the production process, but rather reduce output by rejecting bad products and sometimes borderline or even good parts.

In the case of scrap caused by process, machinery and environmental issues, the most important function of inline vision technology is early detection. Defects can be discovered almost immediately, preventing the need to re-sort a production batch or scrap a large amount of suspect product.

Personnel challenges have significantly accelerated in recent years. It is a common story for manufacturers to have challenges simply hiring enough workers to operate their plant. It has become even more challenging to find and keep sufficiently skilled workers for an increasingly technical manufacturing environment.

Reducing Operator Errors

To address personnel challenges, a major area of continuous development for vision systems has been in their ease of use and security. Some vision-system suppliers have become focused on specific markets. With a high level of know-how for the applications, these companies have developed purpose-dedicated systems, designed specifically for the application and ease of use. Furthermore, modern vision systems can be equipped with individual logins and passwords, controlled access to key functions, and full traceability of operator actions.

With regard to personnel issues, another major advantage of dedicated vision suppliers is the customer’s ability to rely on the supplier for training and support, so that a manufacturer’s vision program does not collapse upon the departure of key users from the company.

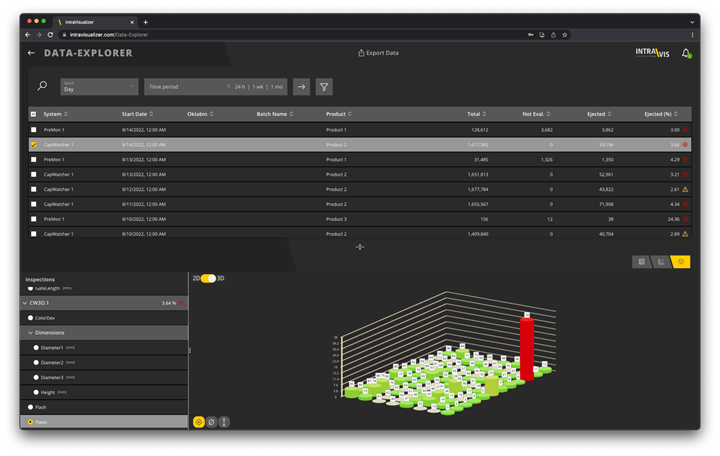

FIG 1 Intravis’ IntraVisualizer remote monitoring software includes a dashboard and trend analysis with Estimated Time to Failure (ETF). (Photos: Intravis)

Digestible and Accessible Data to Prevent Scrap

Today’s vision technology can supply a rich depth of statistics to provide data to diagnose production variations. An operator can review graphs of rejects by defect type during specific periods of time and review image history to see what has occurred. To make the data review more intuitive, information can be grouped by functional elements, rather than by specific camera inspections.

Another key feature of modern vision technology is the ability to provide notifications when processes shift. Warning limits can be programmed so that an alert is raised when inspections are nearing reject limits. This allows identification of issues and preventive action to be taken before defects are produced.

Estimated Time to Failure (ETF) identifies an issue and the time available to take corrective action before defects are produced.

To take notifications to another level, information can be provided remotely, to reach decision makers without requiring their review of each individual vision system on the production floor. One modern feature is email or push notifications when warning limits, reject limits or negative machine states are reached. To take capabilities to another level, some vision-system suppliers provide remote monitoring software (Fig. 1), so that trends can be accessed and monitored through any web-based device such as a PC, laptop, tablet or smart phone. Remote monitoring software can allow the creation of production line “dashboards” visualizing key data that are meaningful to the user.

Furthermore, remote monitoring software can provide more detailed feedback on production trends. For particular product attributes, the software will identify an upward or downward trend, heading towards an upper or lower quality limit, and provide an Estimated Time to Failure (ETF). This function gives key information to the production planners that identifies an issue and the time available to take corrective action before defects are produced.

FIG 2 Intravis’ “Mold Map” technique for cavity correlation of temperature readings of plastic closures helps isolate potential problem areas.

Pinpointing Issues to Identify Machine-Generated Scrap

Advanced vision systems can be used to closely monitor production processes and pinpoint the specific causes of issues so that scrap created by upstream machinery can be promptly addressed.

A classic example is on the filling line after filling and capping. Vision systems that are inspecting fill height and cap application can pinpoint reject rates to individual heads on the filling and capping machines. This is accomplished by a signal interface and tracking of product movement from the filling/capping machine through the inspection system. Software can identify problem filler/capper heads immediately so that corrective action can be taken to prevent prolonged production of defects.

A major example of using vision to pinpoint machinery issues in plastics injection and blow molding is to correlate defects to specific molds and/or cavities. This can be a challenge for many applications since the parts are often not controlled between the molding and inspection areas. In the production of plastic closures or preforms, for example, parts are commonly handled in bulk before feeding into the inspection system. A main technique to address this challenge is to use vision to read cavity numbers and to correlate data and statistics to each mold. Cavity number reading has advanced significantly with the onset of deep-learning algorithms.

One basic use of cavity reading is to “blacklist” specific cavities creating defects, so that those parts are automatically rejected to be reprocessed later. This allows the production line to continue running until the issue can be addressed.

Cavity reading and correlation can create value for additional inspections relevant to the production process. One example is inspection of plastic closures. The vision-inspection system incorporates a temperature measurement of every part, in addition to the cavity reading. The supplier’s web-based remote monitoring software can produce a “mold map” (Fig. 2), indicating the physical location of the cavities in the injection mold, together with temperature data. This easy-to-use graphical data is applied to identify and troubleshoot potential temperature-related issues that are causing defects on the molding machine.

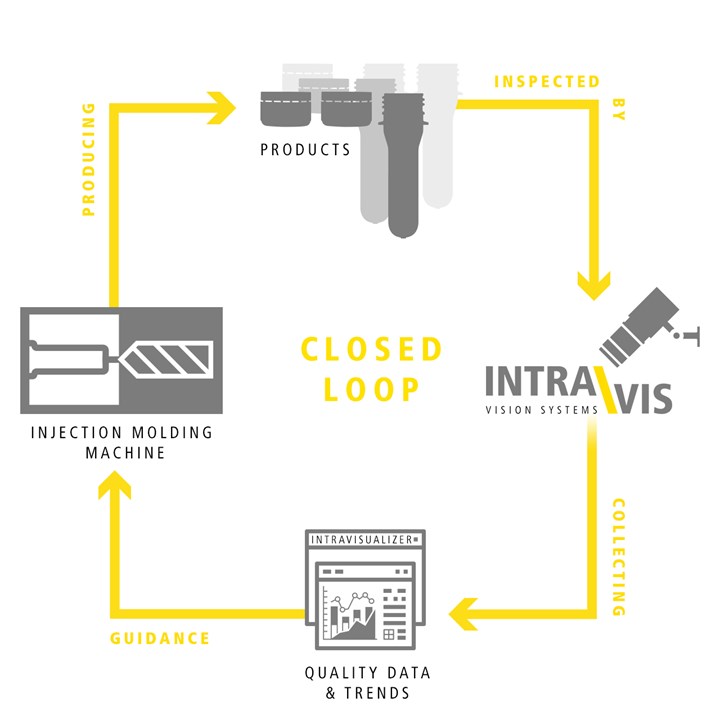

FIG 3 In closed-loop production, the vision system feeds information back to the molding machine to ensure scrap products are never produced.

Using Vision to Close the Loop

The ultimate goal for advanced vision systems is to use the information gathered from every product inspected to “close the loop” — i.e., to provide a feedback loop to the production machine to automatically adjust the machine to prevent defects (Fig. 3). This is a significant step towards achieving “lights out” production as part of an Industry 4.0 program.

One example was implemented with the cooperation of a vision system supplier and a major injection molding machine manufacturer on a plastic closure production line. The vision system provided a highly precise measurement of the closure diameter inline after molding. Diameter values were communicated to the molding machine via an OPC-UA interface, informing the machine that the diameter was moving towards its limit value, and that intervention was necessary. The injection machine automatically counteracted this trend by making appropriate adjustments to the associated process parameters (e.g., injection pressure, melt temperature). After a very short period, the machine corrected the drift and prevented scrap from occurring.

Cavity-number reading has advanced significantly with the onset of deep-learning algorithms.

Another application in plastic packaging is in labeling of containers. The vision system measures the position of every label, including horizontal, vertical and skew information. The data are processed into a digestible format and fed back to a labeling machine with a specially designed servo-driven label-application head. With this continuous feedback loop, the labeling machine will correct its application of the labels to prevent going out of specification.

Envision Greater Productivity

When utilized to their full capabilities, today’s vision systems can play a significant role in reduction and prevention of scrap. Issues caused by operator error can be reduced by partnering with a vision-system specialist with industry-specific know-how embedded in the technology and support. Statistics including trend data can be provided in a digestible format to enable prompt corrective actions. Ultimately, capabilities will continue to advance for vision technology to be used to close the loop and allow lights-out production.

ABOUT THE AUTHOR: Scott Heins is the director of sales & marketing at Intravis Inc. Scott has 30 years of experience providing inspection equipment for the plastic packaging industry. He joined Intravis in 2016 and is located at the company’s U.S. division in Norcross, Ga. Intravis designs and produces turnkey vision systems for plastic packaging, including closures, bottles, containers, preforms and decorated products. Contact: (770) 662-5458; info-usa@intravis.com; intravis.com.

Related Content

Brabender GmbH Bought By Austrian Measurement Company

Leading metrology company Anton Paar buys 100-year old firm, known in the U.S. as C.W. Brabender.

Read MoreMeasuring Technology Specialist Pixargus Acquired by CiTex Group

A global player in optical inline quality control, Pixargus is intensifying presence in U.S. & Asia under CiTex umbrella.

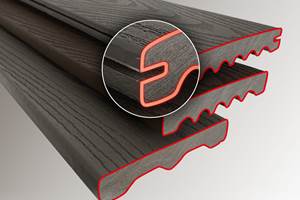

Read MoreInline Inspection System for Wood Plastic Composites

Pixargus’ ProfilControl 7 DX WoodPlasticComposites measure all dimensions and geometrics, including deep grooves.

Read MoreRobust Rotational Viscometer

Versatile viscometer line said to offer robust measurement, repeatability and reporting.

Read MoreRead Next

Second Generation of Autonomous Machine Vision Systems Launched

Inspekto’s new S70 Gen. 2 offers reflection-free images and autonomous machine vision AI which reportedly take vision inspection to new heights.

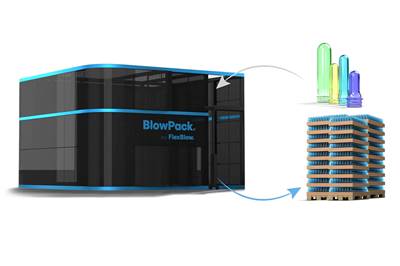

Read MoreFirst Integrated PET Bottle Blowing, Inspection & Palletizing Machine

During K 2022, FlexBlow will demonstrate BlowPack at its plant in Lithuania. It’s described as a “world’s first” integrated system in one machine.

Read MoreInjection Molding: Self-Adjusting, Self-Learning Machine Vision System

Inspekto’s Autonomous Machine Vision (AMV) S70 independently determines the number of samples needed to learn a part’s features and automatically adjusts camera settings for the best possible image.

Read More