Second Generation of Autonomous Machine Vision Systems Launched

Inspekto’s new S70 Gen. 2 offers reflection-free images and autonomous machine vision AI which reportedly take vision inspection to new heights.

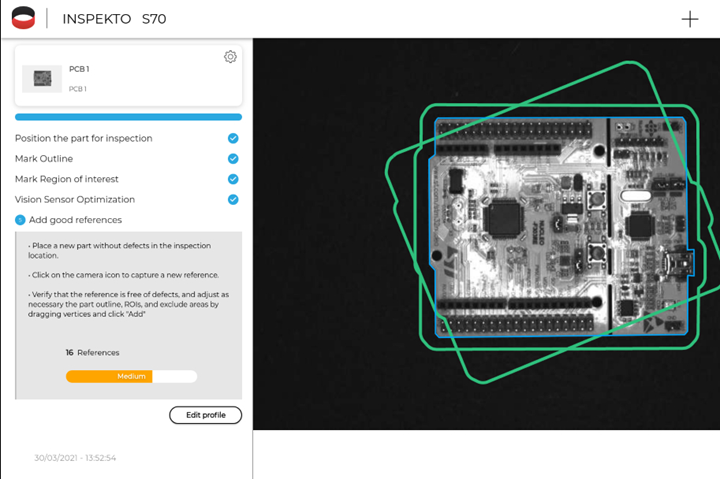

The second generation of the Autonomous Machine Vision (AMV) system for industrial quality inspection pioneered by Israel’s Inspekto (U.S. office in Detroit) has been commercially launched. The new and improved Inspekto S70 Gen. 2 reportedly supports an even higher number of use cases and allows for reliable quality inspection in challenging applications such as highly-reflective materials, moving parts and vibrating platforms.

While allowing for high-quality inspection in wider number of scenarios, the Inpekto S70 Gen.2 is said to maintain its speed and ease of installation. Unlike traditional machine vision solutions, the S70 Gen.2 is an off-the- shelf edge device that users can install in as little as 45 minutes, without any expertise in machine vision or AI. The simple setup procedure only requires an average of 20 to 30 good (OK) sample items and defective (NOK) ones, meaning that no training, data labelling or annotation is required to create the immediate proof of concept (POC).

New and improved characteristics include the possibility to deploy the system in an even higher number of use cases. As opposed to traditional machine vision solutions, built as a project from multiple components and set to inspect only a specific use case, AMV systems are universal, they include both the required hardware and software, and can inspect a wide variety of parts and use cases. This revolutionary feature has been further extended by the possibility to reliably inspect highly-reflective parts, such as metals and plastics.

The built-in 5000K LEDs of the S70 Gen.2, controlled by pulse-width modularization and arranged in several distinct regions, allow the system to autonomously control the direction of the illumination and take several images with varying light direction and intensities. These are then fused to create a single reflection-less HDR image.

Another unique benefit of this patent-pending technology is that it was designed so that the human eye can see no flickering or light variation. This means that if workers are standing nearby, they won’t be disturbed by sudden light changes. If needed, the system automatically adjusts parameters such as exposure, iris, illumination regime, or the sequence of images used to create the final and optimised image, with no human intervention.

The S70 Gen.2 also offers an improved vibration detection and resolution mechanism, as well as the possibility to inspect moving objects running at up to 0.75m/sec. Another benefit is that the inspection cycle time has been shortened to less than 0.5 seconds in most cases, meaning that the system can inspect up to three parts per second.

The second generation of AMV systems is based on continuous research and advancement in Autonomous Machine Vision AI (AMV-AI). This is a unique method of neural networks formulation and architecture, specifically developed to mimic the human cognitive vision process end-to-end.

AMV-AI is powered by three independent and synergetic AI-based engines. The first is the acquisition AI engine, in charge of dynamically adapting the operating parameters of the electro-optical imaging system in real-time to support multiple different vision tasks. The second is the detection and alignment AI engine, in charge of the identification, classification and 3D alignment of any object within the acquired image, after a single input sample. This engine allows the system to recognize the parts it sees in a live video stream and identify the best moment to acquire an image and complete the last task – inspection, which is performed by the third AI engine.

Said Inspekto’s CTO Yonatan Hyatt, “Inspekto has always supported the idea of democratizing quality assurance. What excites us is that the S70 Gen.2 allows also small manufacturers to enjoy the benefits of automated quality inspection, without losing their agility and flexibility. Until not long ago, such technologies were reserved for large corporations.”

Related Content

Powerful and Versatile Infrared Spectrometer

Thermo Fisher Scientific’s Nicolet Apex FTIR is well suited for a wide range of applications including materials analysis.

Read MorePolyfuze Graphics Corp. Partners With RFID Specialists

To help customers navigate the complexities of RFID technology, Polyfuze has partnered with such companies as HID Global.

Read MoreCompact Entry Rotating-Rack Series of Weather Testers Expanded

Atlas’ Xenotest now also available to meet American standards.

Read MoreMeasuring Technology Specialist Pixargus Acquired by CiTex Group

A global player in optical inline quality control, Pixargus is intensifying presence in U.S. & Asia under CiTex umbrella.

Read MoreRead Next

See Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read MoreMaking the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read More