High-Flow PEI ‘Captures’ Burn-In Test Socket Manufacturer

S. Korea’s Sensata is one of the first BiTS makers to adopt SABIC’s new Superflow Ultem.

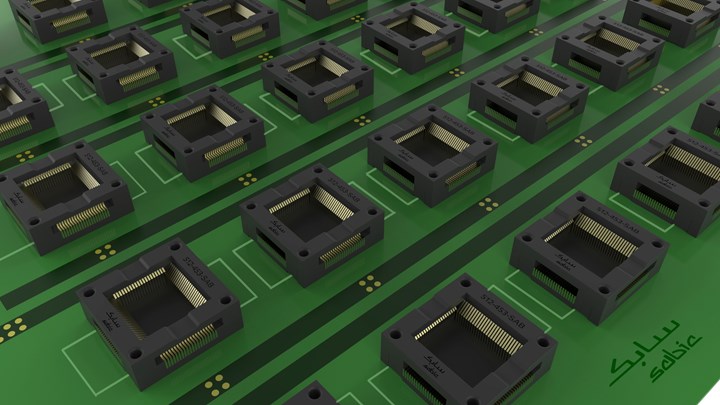

I recently had a discussion with Tommy Oh, design & engineering manager, Sensing Solutions, for Sensata Technologies Korea, which across the global Sensata enterprise provides the majority of the company’s production capacity of burn-in test socket (BiTS)—used to stress-test integrated circuit (IC) chips. Although Sensata R&D teams focused on BiTS design are located in both the U.S. and Japan, the main R&D site for BiTS is in South Korea and, as such, most material specification for new BiTS products is done there. The company recently became among the first BiTS manufacturer to adopt Superflow Ultem PEI from SABIC.

Last year, SABIC commercially launched two new grades in its portfolio of Superflow Ultem resins that reportedly address the trend of electronic component miniaturization to enable smaller, lighter and more-sophisticated devices. Glass fiber-reinforced Superflow Ultem SF2250EPR and SF2270 resins boast exceptional flow properties for molding BiTS. They also have potential for molding thin-wall, high-precision, miniaturized connectors. Their signature flow properties help meet the challenges of complete mold filling and easy release in ever-smaller components.

Balancing flow with toughness, Superflow Ultem SF2250EPR and SF2270 resins are said to be excellent alternatives to incumbent materials such as glass fiber-reinforced LCPs and PES resins, according to SABIC. They reportedly deliver greater weld line strength and mechanical performance than LCPs, and higher tensile strength and modulus, higher weld line strength and lower moisture absorption than PES resins. Not only do the Superflow Ultem resin grades offer similar flow behavior compared to PES--avoiding the need for tool modification, but they have been shown to deliver up to 20% higher strength and modulus, up to 9% lower density, and lower moisture absorption.

According to SABIC, burn-in test socket manufacturers are seeking new material solutions that can support advanced designs for fine-pitch components that are used under extremely harsh conditions, including high temperatures, high pressures and multiple cycles of use. Superflow Ultem SF2250EPR resin is an advanced material that can withstand high-heat burn-in tests up to 302 F/150 C, while offering higher strength and dimensional stability compared to incumbent materials.

Says, Sensata Korea’s Oh, “As the industry advances to finer pitches and miniaturization, existing material solutions present technical limitations in complex BiTS designs due to insufficient flowability and weak weld lines. SABIC’s new Superflow Ultem SF2250EPR solution enables us to successfully develop and commercialize various BiTS devices with superior performance, especially those with lower pitches, such as 0.5 mm and even 0.4 mm. This material has demonstrated approximately 30 percent better ductility, plus much better flowability, compared to alternative PES solutions, especially in thinner-wall weld areas. With the new SABIC material, we anticipate major benefits for our BiTS applications in critical performance areas, including tensile and flexural strength.”

Here's some further details on how Sensata came to opt for this material, as well as the material’s merits and current and future use:

PT: Can you describe BiTS devices, and how your facility produces and assembles them?

Oh: A burn-in test socket is comprised of several molded plastic parts and some metal components, such as metal contacts for electrical conductivity. These parts are mostly sourced from third-party molders and metal component manufacturers. Sensata specifies which materials should be used by our suppliers. Our production facility is basically an assembly line for these plastic and metal parts. Assembly includes simple, manual soldering processes. However, specific information about our facility and processes is highly confidential.

PT: What other materials did Sensata evaluate?

Oh: We previously used Ultem SF2255 PEI resin as well as other materials for our separators and adaptors, depending on part design and requirements. But when finer-pitch designs for adaptors were created, we found the existing resin grade did not offer enough ductility (weld line strength).

Now, we use Ultem SF2250EPR resin in all new models of our burn-in test sockets. The exception is models that require thermal conductivity, and in those cases, we use SABIC’s LNP Konduit compound (thermally conductive PPS compound).

PT: Where is the new Superflow Ultem SF2250EPR used currently and what do you plan for future BiTS production?

Oh: A burn-in test socket is comprised of many components (cover, latch, base, adaptor, separator, stopper, etc.). We are still using other materials for certain parts, but we have adopted the new Superflow Ultem SF2250EPR resin for adaptors. In the future, we may potentially use the SABIC material in other parts within our BiTS models.

In terms of key processing advantages, Oh concurs with SABIC’s claim that within the Ultem family of PEI materials, the Superflow series provides the highest flow properties with up to five times longer flow length than standard glass fiber reinforced Ultem resins. The high flow performance can reduce the number of gates resulting in less breakage, higher production yields, and more durable end-products. Other benefits include lower melt temperature settings that can save energy and minimize outgassing, and accelerated cycle times for higher productivity.

Related Content

General Polymers Thermoplastics to Further Expand Distribution Business

NPE2024: Following the company’s recent partnership buyout, new North American geographic territories are in its sight.

Read MoreAutomotive Awards Highlight ‘Firsts,’ Emerging Technologies

Annual SPE event recognizes sustainability as a major theme.

Read MoreScaling Up Sustainable Solutions for Fiber Reinforced Composite Materials

Oak Ridge National Laboratory's Sustainable Manufacturing Technologies Group helps industrial partners tackle the sustainability challenges presented by fiber-reinforced composite materials.

Read MorePrices Up for All Volume Resins

First quarter was ending up with upward pricing, primarily due to higher feedstock costs and not supply/demand fundamentals.

Read MoreRead Next

Lead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MorePeople 4.0 – How to Get Buy-In from Your Staff for Industry 4.0 Systems

Implementing a production monitoring system as the foundation of a ‘smart factory’ is about integrating people with new technology as much as it is about integrating machines and computers. Here are tips from a company that has gone through the process.

Read More