Exterior Applications' Finalists: SPE Auto Innovation Awards

Check out these three interesting finalists of the 2014 SPE Automotive Innovation Awards within the exterior applications category.

In this month’s issue, I reported on the award winners of the eight categories of the 2014 SPE Automotive Innovation Awards and noted that nearly all other finalists’ applications are newsworthy. Having participated as a Blue Ribbon judge for this event, I was fortunate to see these innovations up close! Here are three innovations in the exterior applications category that grabbed my attention.

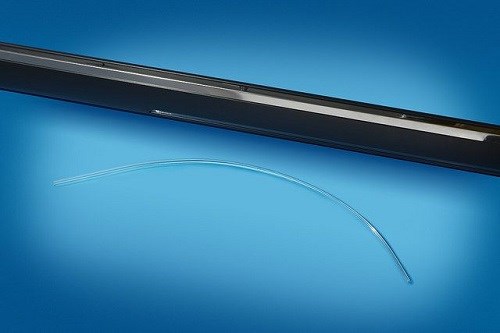

• Transparent Plastic Fin: This first transparent, adjustable fin on a commercial vehicle that allows rear visibility through the fin appears on the 2014 GM Chevy Corvette Stingray Z06. It was molded by 3 Dimensional Services Group of Rochester Hills, Mich., featuring Lexan SLX1432 PC copolymer from SABIC IP. Using a combination of PC/ABS on opaque sections of the fin and Lexan PC/ITR (isophthalate terephthalate resorcinol) on the transparent section, the unique look also improves vehicle handling and control by increasing downforce without impeding or blocking the driver’s line of sight through the rear-view mirror. Additionally, special resin technology provides resistance to impacts, weather, and chemicals while reducing mass40% and costs 60% versus more common metal fins. The innovation is transferable to other OEMs and/or vehicle lines.

• Light Element for Articulating Step: This is the first application of precision light element powered by LEDs and appears on the 2015 GM Cadillac Escalade SUV. Tier I supplier Magna International of Troy, Mich.., used 3M’s PLE urethane, to produce a cast flexible PUR light bar with molded-in light dispersion/extraction geometry. Coupled with a hard-coated extruded PC lens profile, it helps provide improved entry/egress into full-size SUVs equipped with articulating step assists. Unlike conventional light pipes with LEDs, there are no “bright spots”. The system, which is transferable to other vehicles, achieves very uniform lighting for improved safety while sealing the light pipe against heat, water intrusion, stone throws, and shoe impacts.

• Belly Pan with Multiple Airdam Options: This new design that is applicable to other vehicle lines and OEMs appears on the 2015 Ford Mustang, and is injection molded and extruded by US Farathane, Auburn Hills, Mich., of KE308 20% talc-filled PP from KW Plastics. This innovative design allows a single belly pan to accommodate multiple airdam profiles while meeting all program targets for low-speed impact, pedestrian protection, aerodynamic targets, ground clearance, and tooling costs. The resultant system features die-cut airdam extrusion profiles sonically welded to an injection-molded base belly pan, saving $1.2 MM USD in tooling, while providing either improved front-end lift or improved drag at speed depending on the profile used while meeting all program goals.

Want to find or compare materials data for different resins, grades, or suppliers? Check out Plastic Technology’s Plaspec Global materials database.

Related Content

-

Improving Twin-Screw Compounding of Reinforced Polyolefins

Compounders face a number of processing challenges when incorporating a high loading of low-bulk-density mineral filler into polyolefins. Here are some possible solutions.

-

The Fundamentals of Polyethylene – Part 1: The Basics

You would think we’d know all there is to know about a material that was commercialized 80 years ago. Not so for polyethylene. Let’s start by brushing up on the basics.

-

First Quarter Looks Mostly Flat for Resin Prices

Temporary upward blips don't indicate any sustained movement in the near term.