I Didn’t See This Coming

Somehow, an entry-level job in journalism turned into a career at one magazine—49 years and counting. How did that happen?

July 22, 1972 – a day that will live in infamy. Well … not exactly. But it will live in my memory, since that was the day I started work at Plastics Technology magazine.

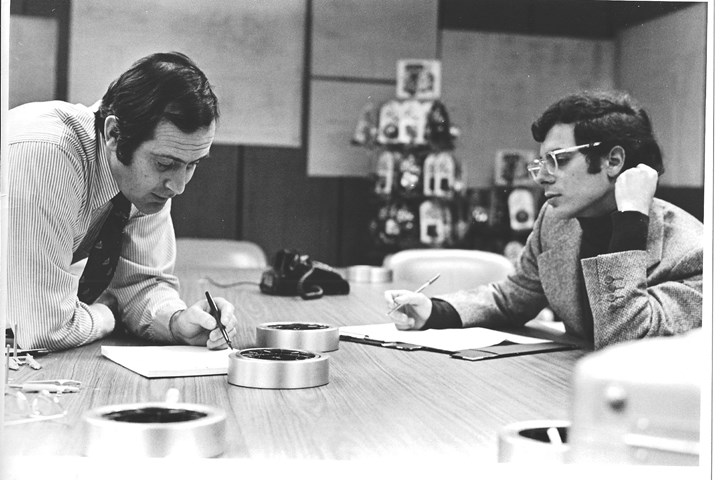

Me (right), learning the craft, 1973.

I was 22 years old, a former English Lit. major, fresh out of journalism school, where I’d spent a year getting closer to the “real world”; and now I was entering the real-er world of work. I phoned my parents to tell them, “Hey, I got a job!” When they asked where, I told them, and they asked, “What’s that?” I said not to worry about it—a couple of years to get some experience, and then I’d be on to something else. (Apparently, PT’s publisher thought so too, and almost didn’t hire me for that reason.) But … 49 years later, here I am. Who knew? –That writing about plastics would be a career? That it would take me to 37 of these 50 states and to 11 other countries? That I would make so many long-term friends and memorable acquaintances? That I would hone my favorite hobby of photography on the job? That in just six years, I would be running the editorial department?

Of course, I didn’t know any of that. I found myself seated at a desk in a hallway with nothing but an electric typewriter and a bottomless stack of press releases. The managing editor instructed me, “When you’re finished with these, I’ll give you some more.” It was a great intro to the field. The releases covered every subject area. (I remember one: the first commercial announcement of PEEK resin. The name was enough to stick in my brain.) I’d study one and then pick up the phone: “So, what does this thingamajig do? What’s new about it? Why is this feature attractive? Is that unique to this product?”

I found I had a valuable knack for a technical reporter: a sense for what I had to understand about a product to write about it, but also what I didn’t have to understand, exactly. Some statements in the releases about the product features just sounded clear and logical, even though I didn’t fully understand the terminology. A larger accumulator increases injection capacity. Maybe I didn’t know what an accumulator was back then, but larger injection capacity made sense for an injection molding machine, and I had no reason to doubt that the two were mechanically related.

I found I was better prepared than the average cub reporter in other ways, too. I had a strong math and science background, especially in chemistry. Unlike most new employees at PT, I could spell polyethylene from the get-go. I knew what an ester was—as in polyester. I could convert °C to °F and kg/m3 to lb/ft3 on my own with just a pencil and scratch paper. And all those college classes in creative writing came in handy, too. Not that I was writing fiction, of course; but, as I would tell junior editors that I would hire in the coming years, “You’re a bit like a novelist, in that you have to put yourself in the mind of someone you don’t know, whose job you’ve never held, and you have to imagine that person’s daily concerns at work and what he or she is looking to get from the article you are reporting and writing.”

I got my first promotion at the end of my first year at PT, when they generously (ha!) let me write an entire 12-page feature section single-handed on a topic that apparently no one else wanted to touch—plastics additives (my chemistry background sure came in handy). A couple of promotions later, I advanced to managing editor, which meant taking responsibility for hiring and firing and the look and content of every editorial page in the magazine. When PT’s editor and publisher decided to focus 100% on the sales side, I became chief editor, and stuck with that for almost 29 years, before moving to my current position as executive editor.

I need hardly say how much the plastics industry has changed during my time at PT. Who remembers when there were at least 20 American builders of injection machines? Or when nearly 70 different brands of those machines were sold here, including imports (and none yet from mainland China)? As for changes in technology, just one article I wrote in 1975 can put things in perspective: It was all about this apparently miraculous little piece of electronics called a microprocessor. I also recall writing the first major stories in PT on mold-flow simulation and something called linear low-density polyethylene, and discovering curious new things at overseas trade shows, like coextrusion blow molding and electric servo drive on injection machines.

The technology of making magazines changed pretty dramatically during my career, as well. When I started, I would fact-check my articles by sending out copies via U.S. Mail or by reading short items, or selected paragraphs of longer stories, to a source over the phone. It was like a lightning bolt when the first fax machine arrived—with that crummy thermal paper that darkened over time. Just imagine—I could send a full text to a source in a minute or two and get a response back the same day! Of course, that was nothing compared with the arrival of the personal computer and then email. No more typewriter eraser ribbons or liquid white stuff to cover up typos. But the computer giveth and taketh away—stories could suddenly disappear without a trace, as I discovered to my chagrin.

An equally earth-shaking change was the transition from typesetting and paste-board layout to electronic page composition. When I started, we sent typed manuscript every afternoon to be driven to a printer 100 miles away. The next morning, the printer would deliver back to us long strips of printed “galleys” the width of a column of type. The art director would cut up the galley strips with scissors, brush a weak glue on the back and paste them up on boards that were ruled into columns of the exact length of our magazine pages. Those paste-up boards were hardly a foolproof technology. Carried around a drafty printing plant, a little piece of a galley—like the heading of a table—might just fall off and no one would notice until the magazine was printed. Yes, that happened.

I failed to mention that before the galleys were pasted up, editors had to proofread them and make deletions and insertions based on corrections that our sources mailed or faxed to us. We would have to guess how those changes would affect the line count, and sometimes we were wrong, as we found out in the next production step. After sending the paste-ups by car back to the printer, we received the full-page proofs the next day. We would proofread those and inevitably make further corrections, and hope we didn’t change the overall line count. We sent the page proofs back to the printer and received the final proofs, called “blues” because that was their overall tint. Once those were proofread and approved—or possibly corrected—the magazine issue was ready to be printed.

What’s different today? Editors and art directors do much of the work that we once paid printers for. Editors create stories on desktop or laptop computers and post them to an online form, which is then transmitted to the art director—who might be in another state, or a neighboring country, rather than in an office next door to mine—who creates page layouts on a computer and posts that to a folder that editors can access online. Editors then proofread and make type corrections in WYSIWYG mode—“what you see is what you get”—so there’s no more guessing about line counts. We see the story almost exactly as it will look in print while we are making the corrections.

In my time at PT, I’ve worked with nearly 60 other editors, including some of the most talented, hard-working and loyal people I’ve ever met. They are what kept me at PT long enough to make a career of it. That, and the unfailing creativity and vibrancy of this industry and the generosity of the people in it whose acquaintance I was fortunate enough to make. On plant visits, I never fail to marvel at how complete strangers will open up to reporters and allow them into a part of their lives. (There are exceptions, to be sure.) And I’ll never get tired of hearing engineers and inventors show off their newest developments. Their pride and excitement is contagious for the reporter, who gets to say in print, “Hey! I just found out about something great, and let me be the first to tell you about it!”

Read Next

Making the Circular Economy a Reality

Driven by brand owner demands and new worldwide legislation, the entire supply chain is working toward the shift to circularity, with some evidence the circular economy has already begun.

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read MoreSee Recyclers Close the Loop on Trade Show Production Scrap at NPE2024

A collaboration between show organizer PLASTICS, recycler CPR and size reduction experts WEIMA and Conair recovered and recycled all production scrap at NPE2024.

Read More