Laser Annealing of Block Copolymers

Could blasting copolymers with temperatures above 1000 F create novel structures and features?

Could blasting copolymers with temperatures above 1000 F create novel structures and features?

Two Cornell researchers say yes in a paper recently published in the American Chemical Society’s (ACS) Macromolecules Journal with a caveat: the materials can only be exposed to the intense laser heat for extremely short durations—between 250 microseconds and 10 milliseconds.

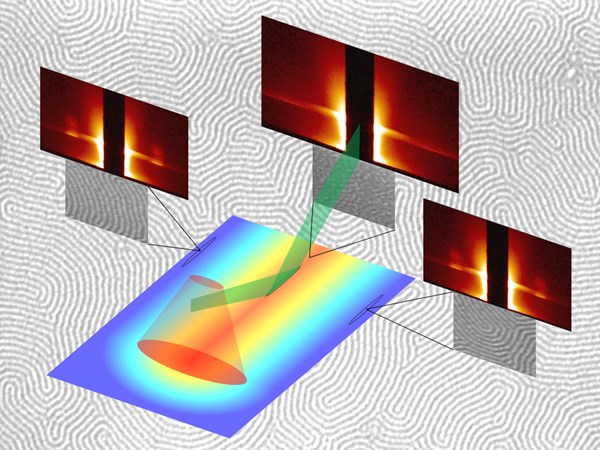

In the experiment, Cornell’s Mike Thompson and Chris Ober worked with a polystyrene (PS) and polymethylmethacrylate (PMMA) block copolymer. They used a laser spike annealing apparatus to push the materials to temperatures up above 1000 F (550 C) for bursts of no more than 10 milliseconds.

According to Alan Jacobs, a graduate student in the lab and lead author on the paper, this this work “opens up a whole new regime for studying the dynamics of polymer motion.”

Normally we think of polymers as being fairly rigid. But when you go to high enough temperatures, they become exceedingly mobile and flexible in a liquid-like state. With laser induced heating, we can reach these temperatures fast enough, and also cool down fast enough, that the block copolymers can reorder and restructure themselves into useful and interesting structures before they begin to burn.

Typically in a block copolymer, like materials group together, resulting in a non-homogenous blend, but short, intense bursts of heat could serve to put the material in a state of “controlled disorder”, which results in fewer defects and unique properties that can actually be dialed in by changing up the length of heating and the temperature. Per Jacobs:

With enough energy in there, they will mix randomly and create a more homogeneous structure at high temperature. Then, as they cool, they are free to adopt the new and unique structures.

The research is supported by grants from the U.S. Department of Defense, the National Science Foundation and the National Institutes of Health. Read more here.

Related Content

-

Prices Up for All Volume Resins

First quarter was ending up with upward pricing, primarily due to higher feedstock costs and not supply/demand fundamentals.

-

Automotive Awards Highlight ‘Firsts,’ Emerging Technologies

Annual SPE event recognizes sustainability as a major theme.

-

The Fantasy and Reality of Raw Material Shelf Life: Part 1

Is a two-year-old hygroscopic resin kept in its original packaging still useful? Let’s try to answer that question and clear up some misconceptions.