Nanodiamonds 'Shine' As Thermal Fillers For Plastics

Advances in nanodiamond fillers present new alternatives for boosting thermal conductivity of plastics for electronic and LED applications.

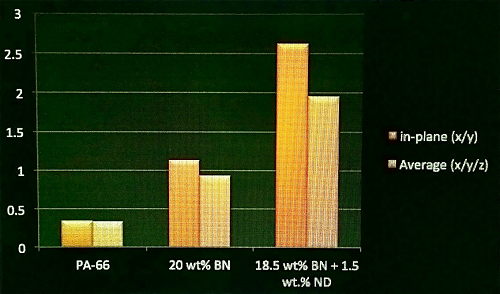

Nanodiamonds (NDs) might sound extravagant for use as thermal fillers in plastics, but Finland’s Carbodeon (U.S. rep. is SiliconSense of Nashua, N.H.) has made significant strides by refining its functionalized nanodiamonds which can deliver a performance increase of 20-100% and allow similar performance improvements with 70% less ND use, greatly reducing their cost.

Carbodeon CTO Vesa Myllymaki says the company is now selling its uDiamond nanodiamonds (ND) in either their powder or dispersion form. “As dispersions, the ND particles are fully dispersed in chosen liquid media—as such, they are available as their primary particles without agglomeration. What this means is that the customer can benefit from the entire available surface area of NDs, giving better performance with less material and cost. While the company is not currently selling the NDs in masterbatch form, this is one of the future options. The company is targeting manufacturers of thermally conductive polymers and compounds as well as thermal filler manufacturers, as NDs can be formulated with established thermally conductive fillers such as boron nitride and alumina.

The performance achieved by uDiamond fillers is a combination of diamond’s extremely high thermal conductivity, Carbodeon’s ability to optimize the ND filler affinity to a range of thermoplastics and other thermal fillers, and its improvements in ND filler agglomeration control. Says Myllymaki, “With the ability to control these parameters, the nanotechnology key paradigm of ‘less gives more’ can truly be realized.” He notes that the active surface chemistry inherent in detonation-synthesized nanodiamonds has historically presented difficulties in utilizing the potential benefits of the 4-6 nm particles, making them prone to agglomerations. Carbodeon functionalizes the surface of NDs with a patented graphite-based coating so that the particles are driven to disperse and to become consistently integrated throughout the plastic.

Late last year, the company published data showing the conductivity of nylon 66-based thermal compounds could be increased by 25% by replacing 0.1% by wt. of the typically maximum effective level of boron nitride (45%) with NDs. In addition, the company recently was granted a patent on nanodiamond-containing thermoplastic thermal composites.

While still more costly than boron nitride or alumina, the enhanced NDs can be used in applications such as thermoplastic LED secondary heat sinks as co-additives with existing fillers. “While there are certain limits on, for example, boron nitride loadings, the overall performance can now be pushed forward with a minimum replacement of existing filler material with our NDs. If a customer wishes to reduce the standard filler concentration but retain certain thermal performance—either to reduce component weight or excess wear of production tools-- according to our calculations, it is cheaper to do this with NDs than with boron nitride materials,” he says.

Related Content

-

PEEK for Monolayer E-Motor Magnet Wire Insulation

Solvay’s KetaSpire KT-857 PEEK extrusion compound eliminates adhesion and sustainability constraints of conventional PEEK or enamel insulation processes.

-

Design Optimization Software Finds Weight-Saving Solutions Outside the Traditional Realm

Resin supplier Celanese turned to startup Rafinex and its Möbius software to optimize the design for an engine bracket, ultimately reducing weight by 25% while maintaining mechanical performance and function.

-

Injection Molded Enclosures Plug into Potential Electric Vehicle Battery Applications

In partnership with material suppliers, Engel is proving out injection molded thermoplastic-based concepts for electric vehicle battery housings, utilizing production tools and dedicated machines at its large press factory in St. Valentin, Austria.