Design Optimization Software Finds Weight-Saving Solutions Outside the Traditional Realm

Resin supplier Celanese turned to startup Rafinex and its Möbius software to optimize the design for an engine bracket, ultimately reducing weight by 25% while maintaining mechanical performance and function.

German Tier 1 automotive systems supplier ElringKlinger had already worked with Celanese’s design engineering team to optimize an injection molded engine bracket for a leading European luxury sedan supplier when Celanese decided to apply an emerging technology to see if further optimization was possible. Celanese’s Computer-Aided Engineering (CAE) team located at its European Technical Centre (ETC), in Meyrin, Switzerland, turned to Möbius software from Rafinex, a software startup based in Luxembourg. Experts in established CAE software, the Celanese team wanted to evaluate Rafinex’s new stochastic topology optimization software to determine its potential utility going forward to help it support customer projects.

Automated Iterative Design

“Stochastic topology optimization” may seem like quite a mouthful. Wikipedia defines “topology optimization” as “a mathematical method that optimizes material layout within a given design space, for a given set of loads, boundary conditions and constraints with the goal of maximizing the performance of the system.” Wikipedia further defines “stochastic optimization” as “optimization methods that generate and use random variables.”

In the case at hand, Möbius software employs a probabilistic approach to generate a large number of potential designs and identify the optimal one. This technology can optimize the structural design of automotive thermoplastic and composite components such as automotive engine mounts, suspension brackets and body panels. Notably, Möbius software also claims to produce designs that meet safety requirements precisely and withstand forces beyond those foreseen during vehicle operation.

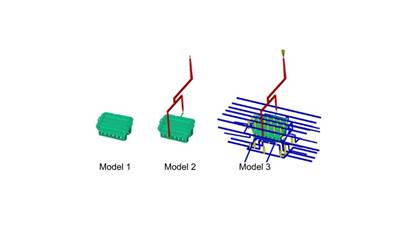

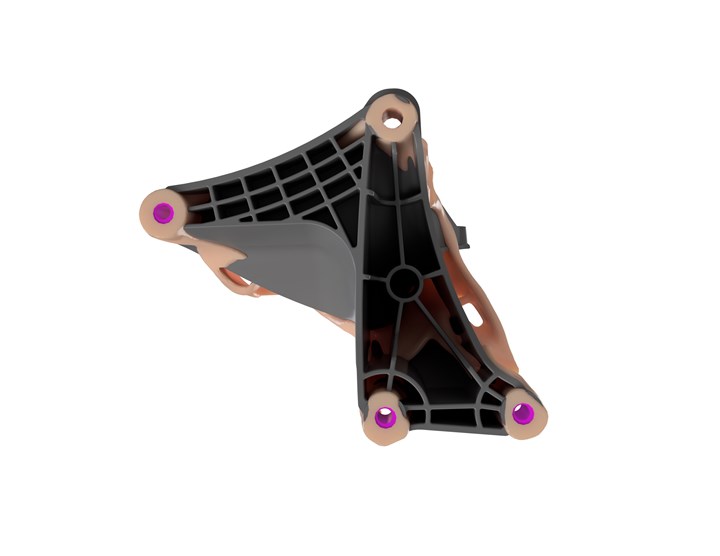

In this view of the front of the engine mount, the salmon-colored elements were generated by the Möbius software, while the brown areas are the original design. (Photos: Celanese)

The software evaluates initial designs based on a set of predefined criteria, including weight, strength, stiffness and durability. The best-performing designs are then used to generate a new set of designs, and the process continues until the optimal design is identified. Depending on the application and its constraints and manufacturing method, that design may be more organic or biomorphic in shape.

What sets stochastic topology optimization apart is its ability to uncover designs and structures that wouldn’t come out of traditional methods. The technology enables engineers to fine-tune the design of automotive plastic parts, resulting in lighter, stronger and more efficient components, cutting weight but maintaining strength in parts where lightweighting was already believed to be maximized.

What sets stochastic topology optimization apart is its ability to uncover designs and structures that wouldn’t come out of traditional methods.

Rafinex offers Möbius using a software-as-a-service (SaaS) model, where users access the program on the Cloud with state-of-the-art Intel Xeon and AMD EPYC processors for efficient computation. Möbius then applies adaptive local mesh refinement technology and optimization algorithms to optimize design. Armin Lohwasser, chief business office and partner at Rafinex, explained that Möbius requires only a browser on the user end. Data transfer, translation, modeling and setup, optimization and validation (including storage) are provided by Möbius.

A Test Case

To test drive the software, Celanese’s automotive team in its ETC decided to run an existing engine bracket molded from Zytel 70G50 (50% glass-filled nylon 66) that had already been optimized through Möbius. Rafinex ran the optimization based on the design space, constraints and load cases Celanese provided. Then the Celanese team evaluated the optimal result for injection molding processability, as well as structural performance.

In this image of the side of the engine mount, the salmon-colored elements were generated by the Möbius software, while the brown areas are the original design.

According to Pieter Volgers, technical programs manager/CAE at Celanese, the biggest challenge for structural components in engineering polymers is to create a sufficiently stiff and robust design using the minimum amount of material. “Traditional design is usually based on experience and previous developments,” Volgers says. “This history is not available for new applications, making the design of these very challenging. As a result, designs tend to be ‘conservative’ or ‘traditional,’ excluding shapes and solutions which could be more efficient.”

Volgers said that enhancing the bracket’s topology using the advanced stochastic optimizer developed by Rafinex enabled Celanese to conduct iterative design studies and eventually recommend a solution that it knew could be successfully injection molded.

Celanese provided Rafinex the available design space for the engine mount with instructions to maintain thickness constraints for the boss, bolt seating/washer areas and holes. The washer projected areas were assumed to be fully constrained, and a rotating load vector was applied in the ZX plane to the boss surface.

Next, Rafinex ran the model through the topological optimization process within its Möbius software. The process was driven by mass targets for maximum stiffness. A brief visual evaluation of the results and design variants led the team to believe the 15% mass target design would be most suitable for further study.

The 15% mass target Möbius results were then compared with the original injection molded rib designs. In the images, the salmon-colored elements are from Möbius designs, while the brown areas are the original design.

Nonlinear structural analysis was performed and compared with the results obtained with the traditional design. The latter included the effect of fiber orientation, as well as more accurate modeling of bolts and bushings. Although important, this was not considered to influence the results so much that it would invalidate the conclusions. This also further validated the Rafinex design, which showed equivalent structural performance.

Depending on the application and its constraints, and manufacturing method, stochastic topology designs may be more organic or biomorphic in shape.

In the final analysis by the team, the Möbius-optimized design resulted in 25% less volume for the engine mount. A subsequent Moldflow analysis of the optimized design showed balanced filling of the part via a single gate, with low injection and holding pressures. Celanese notes that as the optimized design is 25% lighter than the original version, significant opportunities remain to finalize the shape so that it meets all the structural and moldability requirements while still providing significant weight and cost savings.

With the experiment deemed a success, Celanese’s Volgers says that by applying Möbius software in the early stage of development, Celanese could quickly come to an optimal design shape. “The shape not only has a mass potentially even lower than the existing design but a more natural and unconventional shape,” Volgers says.

He also noted that while the Rafinex tool provided a manufacturable shape via injection molding, the design would likely require minor modifications for ease of demolding. Once implemented in a design process, Rafinex expects that five to 10 design variants can be generated per week with Möbius, including structural FEA validation. According to the company, these structural FEA validation runs can be prepared and solved automatically in the browser-based UI. Having established itself in Europe, the company is now eyeing expansion into North America in 2024, according to Lohwasser.

Viewing the engine mount bottom, the salmon-colored elements were generated by the Möbius software, while the brown areas are the original design.

Related Content

Injection Molded Tape and Resin “Sandwich” Technology Debuts

During its Mobility Days in Austria, Engel and KTM Technologies debuted an all-plastic molded motorcycle seat base produced via a tape-sandwich process that can run in a standard molding process.

Read MoreAutomotive Awards Highlight Emerging Technologies

Annual SPE Automotive event gives nods to several ‘firsts’ as well as sustainability.

Read MoreInjection Molded Enclosures Plug into Potential Electric Vehicle Battery Applications

In partnership with material suppliers, Engel is proving out injection molded thermoplastic-based concepts for electric vehicle battery housings, utilizing production tools and dedicated machines at its large press factory in St. Valentin, Austria.

Read MoreAdditive Fusion Technology Optimizes Composite Structures for Demanding Applications

9T Labs continues to enhance the efficiency of its technology, which produces composite parts with intentionally oriented fibers.

Read MoreRead Next

Celanese to Acquire DuPont’s Engineering Plastics

Celanese will acquire nearly all of DuPont’s engineering thermoplastics, except for its Delrin, Multibase and Tedlar products.

Read MoreHow to Achieve Simulation Success, Part 1: Model Accuracy and Mesh Decisions

Molding simulation software is a powerful tool, but what you get out of it depends very much on your initial inputs. Follow these tips to create the most successful simulation possible.

Read More